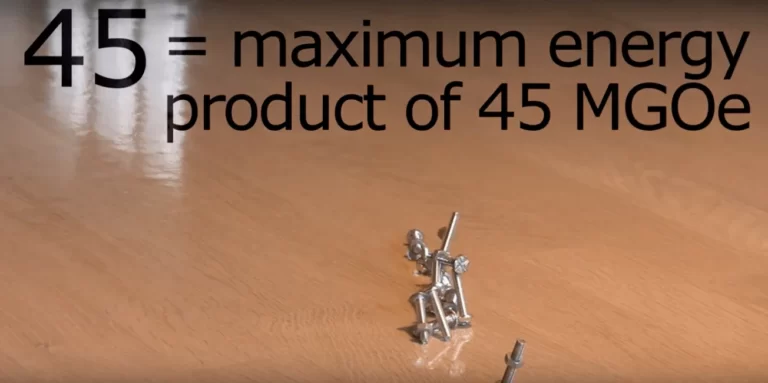

Grades of Magnets

Magnets come in various grades, especially for neodymium magnets (NdFeB). The term “magnet grades” typically refers to the material’s (BH)max or maximum energy product, which is a key value for comparing the strength of neodymium magnet grades. While magnet grades are a reliable indicator of material strength, they do not directly equate to pull force,…