Micro Magnets

Precision Micro Magnets

Possibility starts small. Our precision micro magnets open up a world of potentials that push the boundaries of physics and engineering. If you need some magnets for a microscopic scale, we can help you achieve it.

Don’t hestiate to contact us.

- Material: Neodymium, SmCo, Alnico, Ferrite

- Minimiun Wall: 0.15mm (150 µm)

- Minimium Size: 0.2*0.2mm (200 µm)

- Minimum tube: 0.38*0.14 *2 mm

Small Magnet

If you’re looking for a magnet, it’s not such a small magnet. You can visit our page about small magnets. or contact us directly

What Our Customer Say

What is Micro Magnet

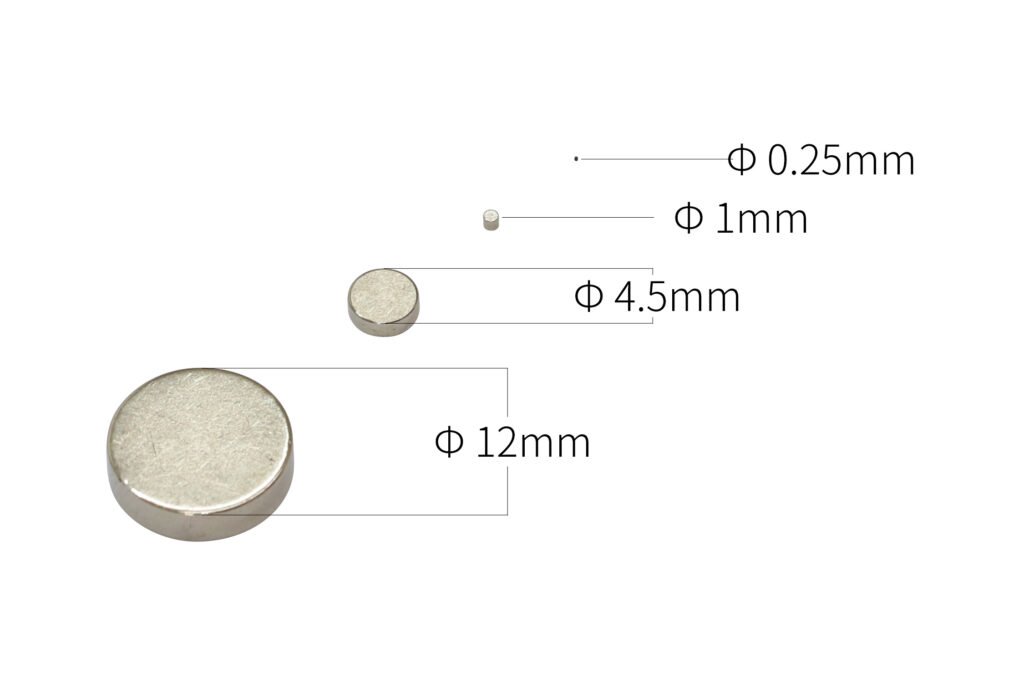

Micro neodymium magnets, also known as tiny or precision neodymium magnets, are ultra-small magnets typically measuring less than 2 mm (5/64 inch) in size. For clarity in discussing technical topics, we classify these minute magnets into two size categories:

• Small magnets (Little magnets): 0.80 – 15.00 mm

• Micro magnets (Tiny magnets): 0.20 – 0.79 mm (200μm – 790μm)

The growing popularity of micro neodymium magnets is evident across various industries, such as consumer electronics, automotive, medical devices, and micro robotics. This trend is driven by the continuous advancements in manufacturing technologies, which enable the creation of increasingly compact designs. Micro neodymium magnets play a vital role in reducing the overall dimensions of these products.

The use of micro neodymium magnets has expanded to include previously unimaginable applications. One notable example is Minimally Invasive Surgery (MIS). In procedures involving coronary arteries, which are only 3-4 mm in diameter, the required magnet diameter is 1.35 mm or even smaller. The versatility and precision of micro neodymium magnets are unlocking new possibilities in various fields.

Features of Micro Magnets

Custom micro magnets are tough to make, and it’s difficult to find supply information. If you search on some major B2B websites, those results are usually for small magnets of quite a few millimeters, not micro magnets.

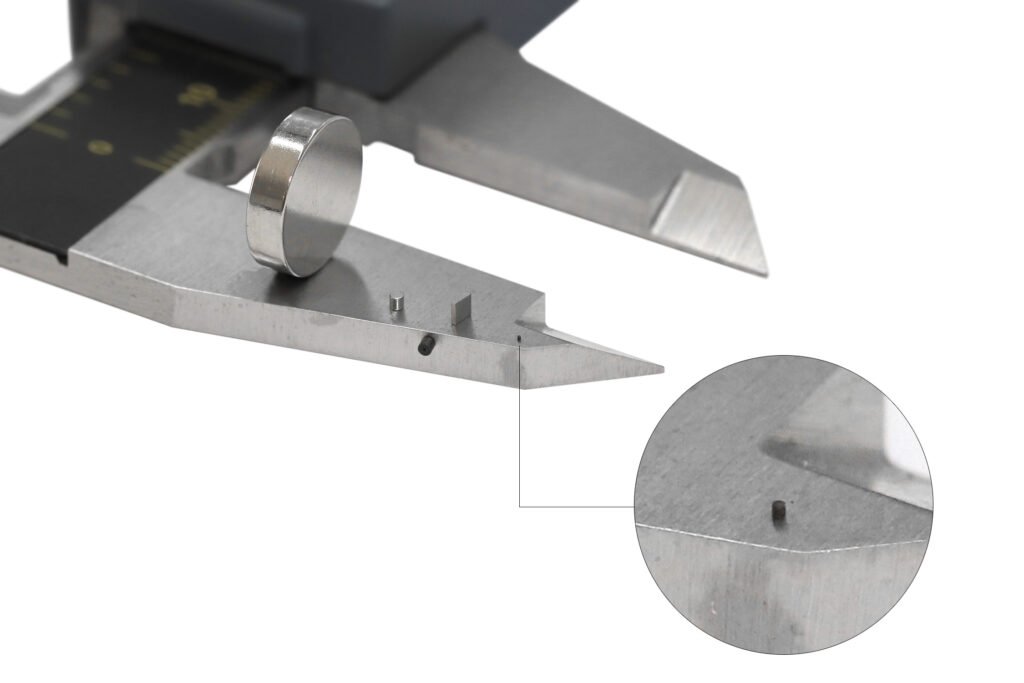

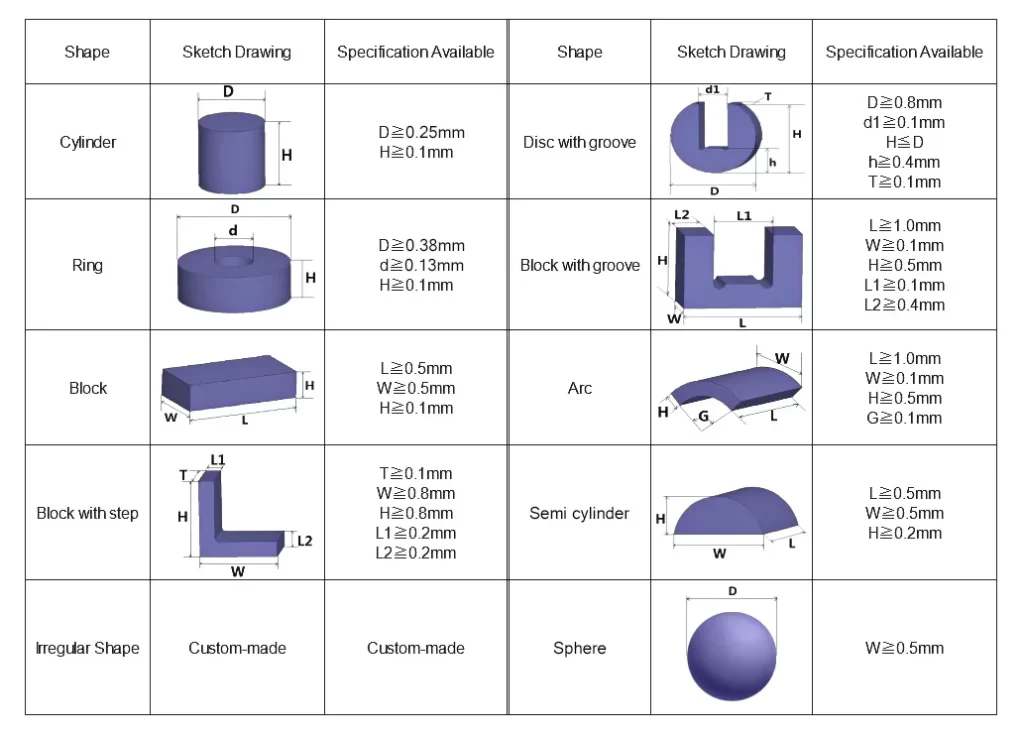

• Across the country, only several magnet manufacturers can produce such tiny magnets with unique shapes – like drilling a hole in a micro magnet, or the form is irregular (like the picture below).

As a custom neodymium magnet supplier, Osenc takes micro magnets as one of our most important focuses. We can produce micro magnets with different materials. Like Neodymium Iron Boron, Samarium Cobalt, Ferrite, FeCrCo and Alnico.

Measurement Unit

Lots of people use the same measurement unit as regular magnets. Both of them are mm. For example, people can describe the disc magnet as 5*5mm. Block magnet as 5*6*9mm. (Please note the last number is magnetic direction)

But in the scientific research, scholars like use μm to measure magnets. like in the paper “A micro electromagnetic actuator with high force density” (Yue Wang)

Minimum Dimensions of Micro Neodymium Magnets

Osenc can produce micro magnets with the dimensions below as a custom magnet supplier.

• Minimum block: 0.2*0.2*0.2 mm

• Minimum disc: 0.2*0.2 mm

• Minimum tube: 0.38*0.14 *2 mm

• Tolerances: between +/- 0.005mm and +/- 0.020 mm

• Minimum hole diameter: 0.10 mm

The giant thin magnet we made is 50*50*0.2mm (This is a big challenge)

Grades

Neodymium magnets are graded based on the strength of their magnetic field. A number indicates the grade of a neodymium magnet. A more significant number indicates a stronger magnetic field.

Neodymium magnets have different grades, ranging from N35 to N55, and they also have high-temperature grades for special applications, like H, M, SH, EH, and AH.

You can refer to our introduction to neodymium magnet grades. It will be helpful for you to determine which grade is the most appropriate for you.

Besides the technical possibilities about which grades we can offer, we recommend choosing micro neodymium magnets of the top grades – N52, N54, and N55.

• The sizes of micro magnets are tiny. Therefore, if you choose magnets of lower grades, they may not be able to offer magnetism at an optimum level.

• Second, magnets of lower grades are more difficult to process and more likely to get damaged during applications.

For these reasons, micro magnets of the top grades are more logical choices than lower grades.

Coatings

Neodymium magnets are sensitive to the working environment. The humidity and even other corrosive elements can cause them to corrode quickly.

To improve the durability of neodymium magnets, we will need to apply a layer or even multiple layers of coatings on their surfaces. Meanwhile, this will also make the magnets more resistant to scratches and other types of damage.

Osenc offers custom neodymium magnets with several different types of coatings. Like Nickel, Zinc, epoxy, Parylene, etc. Each of them has its unique properties and benefits.

Please refer to neodymium magnet coating to pick the most appropriate coating for your magnets.

The dimensions of micro neodymium magnets are already tiny. Therefore, they need to have high precision to function properly. For this reason, customers have to consider the tolerance of different coatings. We must avoid the issue that the coating ruins the magnets’ precision.

In some cases, the thickness uniformity of the coating needs to be appropriate. Somewhere thick and somewhere thin. This is not because the coating service providers deliberately make defective products but because of the nature of such coating techniques.

Don’t hesitate to get in touch with us if you have strict requirements on the roughness and tolerance of the magnet surface.

What are micro magnet use for?

Micro magnets are used in a wide range of applications across industries. Some common uses of micro magnets include:

1 Electronics: Micro magnets are used in various electronic devices, such as hard drives, sensors, and microphones, to convert electrical signals into mechanical motion.

2 Medical equipment: The micro magnets are used in medical equipment, such:

MRI machines, create strong magnetic fields that can produce detailed images of internal organs and tissues.

Medical micro robot,uses magnets for navigation and control within the body for precise drug delivery and surgical procedures.

In the medical device industry, minimally invasive surgery (MIS) and medical micro robot have always had higher and more requirements for micro magnets. They require smaller sizes than other industries. Because they have no choice.

For example, in the MIS, the diameter of human coronary arteries is only 3 to 4 millimeters. That means the magnet diameter should be 1.35 or less. otherwise, catheters containing magnets risk injuring the blood vessels.

In the subretinal injection studies (Like: A Magnetically Navigated Microcannula for Subretinal Injections, Samuel L. Charreyron), the magnet is a very tiny tube magnet, just 400 μm OD, 270 μm ID, and 2mm length.

3 Manufacturing: Micro magnets are used in manufacturing processes to hold parts together or align them in a precise position.

4 Research: Micro magnets are used in research applications, such as studying the properties of materials at a microscopic level or developing new technologies.

In summary, micro magnets have a wide range of applications in electronics, medical equipment, manufacturing, and research. Their small size and strong magnetic properties make them a versatile and valuable tool in various industries.

Where to buy?

You can buy these micro magnets from Osenc.

Osenc has an advantage on the tiny magnets. If you would like to purchase some micro magnets, don’t hesitate to contact us.

We offer lots of micromagnets to research institutes, universities, and companies.

FQA

With our experience, such strong mini magnets are use in medical products , aircraft instrument sensor and microrobotics.

In medicine, they enable targeted drug delivery and enhance surgical instruments for less invasive procedures.

In microrobotics, they function as actuators for precise movement and are integral to sensing and control systems, allowing accurate navigation and positioning.

Overall, micromagnets provide precision, control, and efficiency in these applications, leading to improved patient outcomes and new possibilities in both fields.

Parylene.

In lots of medica case, customers choose Parylene.