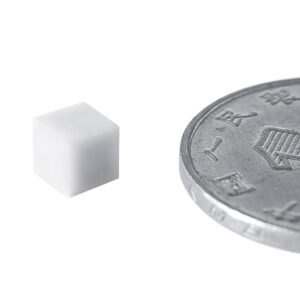

plastic magnets

What is plastic coated magnets?

Plastic coated magnets refer to magnets that have been enveloped within a protective plastic casing. This encapsulation provides enhanced durability and protection, making them increasingly sought-after in various applications. Most of plastic magnets are wrapped with neodymium magnets.

Types of Plastic Coatings

Semi-Wrapped Magnets:

Semi -wrapped means insert molding. These magnets have a partial plastic covering. While they offer some protection, they are primarily used for aesthetic purposes. The magnets housed within are typically of the ferrite magnets, like whiteboard magnets and push pin magnets.

Fully-Wrapped Magnets:

Fully-wrapped also name over molding. These magnets are entirely encased in plastic, ensuring optimal protection. Such magnets predominantly house neodymium iron boron due to their superior strength and vulnerability to external factors.

Materials Used for Coating

Key Features

Plastic coated magnet has some features that you should note:

Waterproof

The plastic coating ensures resistance to water ingress, making these magnets suitable for applications where exposure to moisture is anticipated. The typical waterproof magnet is a button magnet in clothing.

Durability

They offer protection against rust, scratches, and corrosion, particularly in challenging environments like seawater, acidic and alkaline chemicals.

acidic and alkaline chemicals

Stirring bar in the laboratory, where acidic and alkaline chemicals are everywhere. In this case, using the plastic material PTFE can protect the magnet very well.

Seawater

Coral fragment rack. The fish tank used for cultivating corals is filled with high-salt water. Ordinary coated magnets cannot withstand it for a long time.Anti-corrosion Especially in seawater, plastic coating is a must.

Enhanced Strength

The plastic casing provides an added layer of structural support, minimizing the risk of breakage, especially in the case of neodymium magnets.

Surface Protection

Their soft plastic exterior prevents potential scratches on surfaces they adhere to, such as whiteboards.

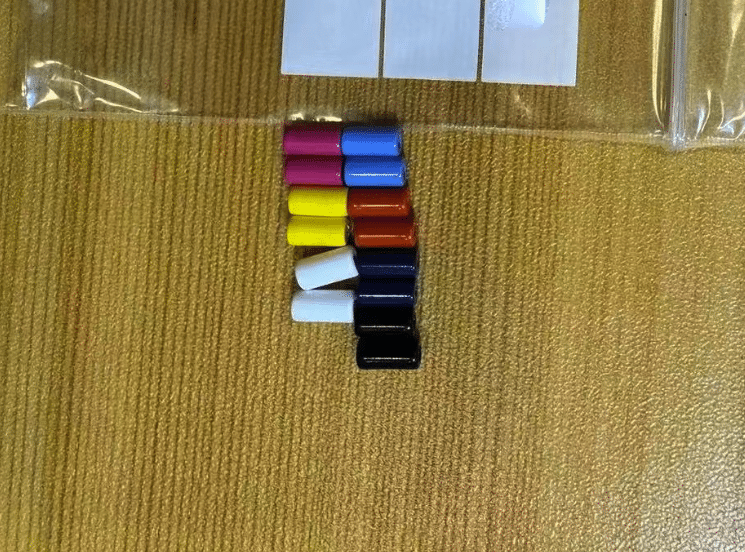

Color Variations

Plastic-coated magnets are available in a spectrum of colors, facilitating organizational tasks and aesthetic preferences in various settings.

Applications