Precision Micro Magnets - Neodymium Micro Magnets

When you’re buying micro magnets for production, “tiny” isn’t the hard part—repeatability is. Our micro neodymium magnets (NdFeB) and other neodymium micromagnets are built for designs where a few tenths of a millimeter changes fit, field, and yield—compact sensors, micro actuators, microrobotics, and lab-to-pilot builds. Share your drawing and stack-up, and we’ll help you lock OD/ID/thickness, coating build, and magnetization—then validate with samples before you commit to volume (often listed as a micron magnet or mikro magnet in EU docs).

- Material: Neodymium, SmCo, Alnico, Ferrite

- Minimiun Wall: 0.15mm (150 µm)

- Minimium Size: 0.2*0.2mm (200 µm)

- Minimum tube: 0.38*0.14 *2 mm

(Note: For smallest neodymium magnets, feasibility depends on geometry, coating thickness, and handling yield. Send your drawing + quantity + coating requirement, and we’ll confirm manufacturability and a realistic tolerance window before sampling.)

Hot-Selling Micro Magnets

What is Micro Magnet

Micro magnets are ultra-small permanent magnets where tolerance and coating build directly change fit and field, so they’re part of the functional spec—not a “nice-to-have.” For clarity, we use:

• Small magnets: 0.80–15.00 mm

• Micro magnets: 0.20–0.79 mm (200–790 μm)

In this range, most teams choose NdFeB for strength-to-volume, but your real limiter is usually handling yield + coating uniformity + air gap in the stack-up (often called a micron magnet in research notes, or mikro magnet in EU documentation).

Features of Micro Magnets

Built for production: repeatable dimensions, coating control, and consistent magnetization for micro magnets and micro neodymium magnets

Common shapes: disc, block, cylinder, ring, tube, ball (custom micro forms available)

Grades: N35–N55, plus temperature grades on request when heat is a risk

Coatings: NiCuNi / Zn / Epoxy / Parylene options (coating build affects final OD/ID)

Packaging for assembly: trays, tape-and-reel, or custom fixtures for pick-and-place

Micro-part reality: brittle material—specify handling, cleanliness, and inspection needs early

Measurement Unit

Most RFQs for micro magnets use mm, while research notes may call them a micron magnet in μm. Either is fine—but always specify magnetization direction on the drawing. In micro assemblies, one wrong assumption (like treating the last dimension as the magnetization axis) can turn a “perfect sample” into a field-direction mismatch at build stage.

Minimum Dimensions of Micro Neodymium Magnets

Osenc can produce micro magnets with the dimensions below as a custom magnet supplier.

- Minimum block: 0.2*0.2*0.2 mm

- Minimum disc: 0.2*0.2 mm

- Minimum tube: 0.38*0.14 *2 mm

- Tolerances: between +/- 0.005mm and +/- 0.020 mm

- Minimum hole diameter: 0.10 mm

If you’re working with ultra-thin parts (for example, 50 × 50 × 0.2 mm), we’ll confirm flatness, coating uniformity, and packaging to reduce cracking and chipping during transit.

Grades of Micro Magnets

Neodymium grades (N35–N55) describe material capability, but they don’t guarantee performance once your assembly adds coating, adhesive, housings, or any air gap. For micro neodymium magnets / neodymium micromagnets, volume is so small that many builds start at N52–N55 to keep usable field after losses. If heat is possible, prioritize a temperature grade first—because avoiding irreversible loss matters more than chasing the highest N-number.

Coatings of Micro magnets

NdFeB micro magnets can corrode quickly in humidity or salt exposure, so coating should be treated as part of the spec—not an afterthought. Common options include Nickel, Zinc, epoxy, Parylene, selected based on corrosion risk and wear. For smallest neodymium magnets, coating thickness isn’t “free”: it changes effective OD/ID and can become a real air gap in your stack-up. If you’re tolerance-sensitive, confirm coating type, thickness target, and how thickness is measured before sampling.

What are micro magnet use for?

Micro magnets are used when you need reliable magnetic force in a very small space—for sensing, holding, positioning, or actuation in compact products. They’re common in electronics, medical devices, precision hardware, and small mechanical assemblies where every millimeter matters.

Sensors & detection: Hall sensors, reed switches, proximity/position sensing

Micro motors & rotors: small BLDC motors, encoders, magnetic coupling

Fastening & latching: tiny closures for cases, covers, doors, lids

Alignment & positioning: jig fixtures, precision locating, repeatable docking

Electronics & connectors: magnetic charging tips, pogo-pin alignment, cable ends

Medical & lab devices: small instruments, disposable cartridges, microfluidic fixtures

Consumer products: earbuds/headphones, phone accessories, wearables, small gadgets

Modeling & crafts: miniature parts, hobby builds, prototyping

Industrial fixtures: pick-and-place aids, holding small metal components during assembly

Where to buy micro magnet?

To quote micro magnets accurately (and avoid spec mismatches), please send:

- Drawing + quantity.

- OD/ID/thickness tolerances.

- Coating type (and any max coating build). Agnetization direction,

- Operating temperature.

- Your real stack-up/air gap.

If you’re sourcing micro neodymium magnets for assembly, tell us your packaging preference (tray or tape-and-reel) and we’ll recommend the most stable option before you move into volume.

FQA

Micro magnets are ultra-small magnets—often under 4 mm (commonly 1–3 mm)—made for assemblies where tiny tolerances matter. Most micro magnets use Neodymium (NdFeB) for maximum strength in a small footprint, while Samarium Cobalt (SmCo) is chosen when higher temperature stability is needed.

Typical size range: 1–3 mm features; often custom micro parts

Common materials: NdFeB (strongest mini form), SmCo (better heat stability)

Where they’re used: electronics, sensors, medical devices, micro-actuators

With our experience, such strong mini magnets are use in medical products , aircraft instrument sensor, mechanical watches, and microrobotics.

In medicine, they enable targeted drug delivery and enhance surgical instruments for less invasive procedures.

In microrobotics, they function as actuators for precise movement and are integral to sensing and control systems, allowing accurate navigation and positioning.

Overall, micromagnets provide precision, control, and efficiency in these applications, leading to improved patient outcomes and new possibilities in both fields.

A small neodymium magnet can feel “surprisingly strong” because neodymium (NdFeB) packs a lot of magnetic energy into a tiny volume. In real use, strength depends on grade, size, shape, coating, air gap, and the steel surface. For example, a 2-gram (0.07 oz) magnet can sometimes lift far more than its own weight—under ideal, flat-to-flat contact conditions.

What affects pull the most: magnet grade (e.g., N35–N52), face area, thickness, and the air gap

Best-case vs real-world: paint, plating, curvature, and thin steel can reduce holding force fast

Why it’s popular: high pull-to-size ratio + good resistance to demagnetization for many applications

The main downside of a neodymium magnet is that it’s not “tough” material. NdFeB is brittle, can chip or crack, and it can corrode if the coating is damaged—especially in humid or salty environments. Standard grades also start to lose strength as temperature rises; many typical neodymium magnets are rated around 80°C (176°F) unless you choose high-temp grades.

If you’re shopping for the strongest small magnets, you’re typically looking at high-grade Neodymium (NdFeB)—especially N56 where available. At Osenc, N56 neodymium magnets are positioned as top-end options for maximum strength in a compact size, often with nickel-copper-nickel plating for corrosion resistance. If you need a broader mix of sizes, N52 is also a common “high power” choice in tiny formats (for example, 1/8" × 1/16" discs).

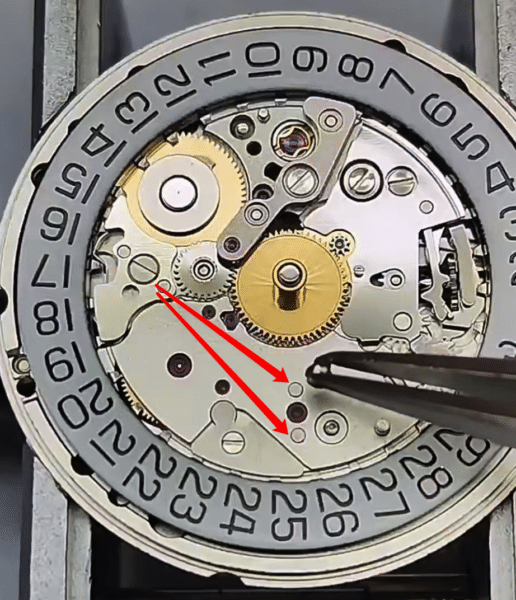

Generally speaking, mechanical watches are highly sensitive to magnetism. People have to avoid any magnetic interference with it. That is why people believed that mechanical watches do not contain magnets. However, there are exceptions.

Some mechanical watches, such as those powered by the ETA 2895-2 movement, they have two pieces very micro magnets. They are use for balance the second wheel. These magnets are carefully engineered with very low magnetic field strength to prevent the magnetization of other components, which could otherwise compromise the watch’s accuracy.

Parylene.

In lots of medica case, customers choose Parylene.

Let‘s Realize Your Grand Plan Together

- [email protected]

- 0086 139 2737 7121

- Changping, Dongguan, Guangdong 523000, China

- We will respond to you within five minutes.