You would find answers to most of the usual questions people ask about magnets and magnetism, about the history of magnetism, magnetic materials, magnetic properties, magnetic orientation, magnetic poles, and others. To learn more technical details regarding these aspects, have a look at our Magnetics-101-Design Guide.

Request a quote or call us today and see what we can do to assist in your specialty needs. MagnetShop.com also stocks large quantities of neodymium, samarium cobalt, alnico, ceramic, and flexible magnets that can be purchased online.

1. History

Ancient Greeks and Chinese learned that some rare stones were naturally magnetized, which were known as lodestones. These stones had the power of drawing little bits of iron most miraculously, and were discovered to always point in the same direction when left free to swing on their own, attached by a piece of string, or floating on water. The magnets were used as a primitive compass, as early sailors depended on these magnets to guide them in the direction they were moving in the sea.

The term magnet is derived from Magnesia, a district in Thessaly in Greece, where it is thought that the original lodestone was mined.

Over the years, the magnets have developed into the high-strength ones that we have today. It was found that by forming alloys with different materials, it was possible to produce similar effects as the ones occurring in the natural lodestone rocks, and enhance the degree of magnetism.

The first man-made magnets were, however, invented in the 18th century. Advances in the development of more powerful magnetic alloys were extremely slow until the 1920s, when alnico magnetic alloys (a nickel, aluminum, cobalt alloy) were developed. In the 1950s and 1970s, ferrite and rare-earth magnets were invented, respectively. Since that time, magnetism has expanded exponentially in the field of science, and miniature and powerful devices have become possible due to the existence of high-powered magnetic materials.

2. Fundamentals of Magnets and Magnetism

What exactly is a magnet?

Magnets are produced by putting a magnetic substance, which is usually iron or steel, in a powerful magnetic field. This way, permanent, temporary, and electromagnets can be made.

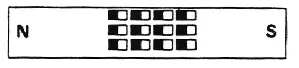

The atoms in materials that are easily magnetized, like iron, steel, nickel, and cobalt, are organized into small particles, known as domains. The domains, though much smaller than a microscope, have millions of billions of atoms each, and the domain resembles a mini-magnet. When a magnetic material is put in a strong magnetic field, the individual domains, which are usually oriented in every direction, will slowly swing in the direction of the field. Neighboring domains are also taken over by them. In case the majority of the domains are oriented in the field, the material turns into a magnet.

Magnetic domains before magnetization

Magnetic domains after magnetization

What does a magnet actually do?

Magnets affect the following:

- Pull towards itself some substances, including iron, nickel, cobalt, some steels, and other alloys.

- Apply either an attractive or repulsive force on other magnets (poles repel, opposite poles attract).

- Influence electrical conductors in the case of a moving magnet and a moving conductor.

- Exert an influence on the trajectory of the electrically charged particles in free space.

According to these effects, the magnets change the energy acquired in one form to another, without having to lose their own energy. The functions of magnets include:

- Mechanical to mechanical, e.g., attraction and repulsion.

- Mechanical to electrical, e.g., generators and microphones.

- Electrical to mechanical, e.g., motors, loudspeakers, charged particle deflection.

- Mechanical to heat, e.g., eddy current and hysteresis torque equipment.

- Magnetic resonance, Hall effect devices, and magneto-resistance.

How are magnets manufactured?

Contemporary magnet materials are manufactured in the form of casting, pressing and sintering, compression bonding, injection moulding, extruding, or calendering. After being produced, the magnets usually require additional processing such as grinding or other machining operations, and further assembly into an even higher assembly. Go to our manufacturing and assembly page to find out about our custom machining and assembly.

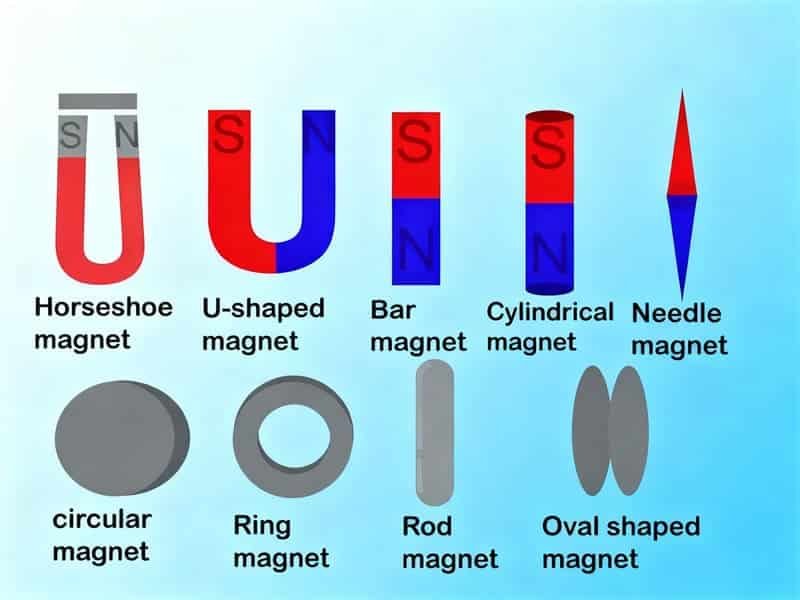

What different types of magnets exist?

There exist three categories of magnets, namely permanent magnets, temporary magnets, and electromagnets.

Permanent magnets do not require any external magnetism source or electricity that supply the magnetic field.

Temporary magnets act as magnets when bound or near a source of a magnetic field, but do not exhibit this property once the magnetic field source is removed.

Electromagnets need electricity to act as a magnet.

Permanent magnet materials that are used in order to create permanent magnets are of numerous types with their own special features. Every material has a lineage of grades, which possess slightly varying properties, though of the same composition.

What are permanent magnets made of?

The modern permanent magnets are made of special alloys that have been discovered through research to produce better magnets. Currently, the most widespread types of permanent magnet materials are aluminum-nickel-cobalt (alnicos), strontium-iron (ferrites, or ceramics), neodymium-iron-boron (a.k.a. neodymium magnets, or super magnets), and samarium-cobalt-magnet-material. (A combination of the samarium-cobalt and neodymium-iron-boron families is referred to as the rare-earth). Learn more about How Are Neodymium Magnets Made?

What are rare earth magnets?

Rare Earth magnets are magnets made up of the rare-earth group of elements. The most general types of rare-earth magnets include the neodymium-iron-boron (neo magnets) and samarium cobalt (SmCo magnets).

What is meant by a temporary magnet?

A weak field is enough to easily magnetize soft iron and some of the iron alloys like permalloy (a blend of iron and nickel). The magnetism is lost, however, as soon as the field is removed. These substances are good temporary magnets, such as in telephones and electric motors.

What is an electromagnet?

Electromagnets are applied where extremely powerful magnets are needed. Electromagnets are created by inserting a metal (in the form of a core) into a coil of wire transmitting an electric current. The coil has electricity that generates a magnetic field. The intensity of the electromagnet is determined by the intensity of the electric current and the coiling of the wire. It is polarized with the flow of current. During current flow, the core can act as a magnet; however, when the current is cut off, the magnet-like qualities disappear immediately. Electromagnets are used in electric motors, televisions, maglev trains, telephones, computers, and most other modern devices.

What are eddy currents in magnetism?

They are electrical currents, which are induced by the movement of a magnetic field in relation to an electrical conductor that has been positioned in access to the magnetic field. These eddy currents, in turn, develop a magnetic field which then works to prevent the relative movement of the original magnetic field and the electrical conductor.

How much do magnets typically cost?

Magnet materials may differ greatly from each other. The following is a rough estimate of magnet prices.

Note: the costs indicated in this column are relative costs, and they depend on large quantities of magnet materials, which are not characterized by any special machining or other features.

Compared to copper alloys, neodymium magnets can be extremely expensive on a cost-per-pound basis. They are, however, not so expensive, on a cost per BHmax basis. With a stronger magnetic field, the whole device into which the magnet enters can be made very small. This results in a saving of cost that is in favor of stronger magnet materials.

Are there industry standards for magnets?

Yes. The Magnetic Materials Producers Association (MMPA) and Magnet Distributors and Fabrications Association (MDFA) have set standards. The two associations are currently known as the International Magnetics Association. The following are some of the publications and standards that are generated by these organizations for your convenience.

Type of application: Whether the magnet is needed for holding, lifting, separating, moving, sensing, or any other purpose.

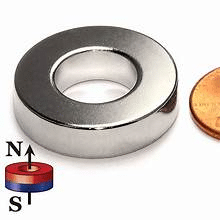

Preferred magnet shape: For example, disc, ring, block, cylinder, sphere, or custom geometry.

Required magnet size: Specify exact dimensions such as diameter, length, width, height, and thickness.

Tolerance requirements: Indicate how much dimensional variation is acceptable for your application.

Operating environment: Consider conditions such as high temperature, exposure to humidity, outdoor vs. indoor use, or contact with corrosive materials.

Required magnetic strength: Define the pull force, Gauss level, or grade (e.g., N35, N42, N52) needed for the job. (Learn more about Grades of Magnets)(N42 Vs N45 Vs N52 Magnet, N35 Vs N52 Magnet)

Budget limitations: If the magnet must not exceed a certain price, this will help determine which materials or grades are suitable.

Quantity needed: Indicate whether you need single samples, small batches, or large production quantities.

Understanding the basics of magnetism requires materials that behave predictably. Osnec produces magnets with consistent performance across polarity, field distribution, and material response, which makes them suitable for explaining fundamental concepts. Students and engineers can observe uniform field behavior, making the basic principles of attraction, repulsion, and orientation easier to demonstrate and analyze.

3. Understanding Magnetic Strength

How long does a magnet retain its strength?

By keeping an object that has a magnet in it away from things that influence it negatively, like power lines, other magnets, high temperatures, etc., a magnet will keep its magnetism for a longer time.

What factors can affect a magnet’s strength?

The factors that might influence the strength of a magnet are:

- Heat

- Radiation

- Powerful electric currents near the magnet.

- Other magnets in proximity.

- Unless they are coated, neodymium magnets will corrode in humid environments with a high level of humidity.

- Modern magnet materials are immune to shock and vibration, unless it is great enough to cause mechanical damage to the material.

Do magnets lose their strength over time?

Contemporary magnet substances do not lose a very limited portion of their magnetism with time. In the case of samarium cobalt magnets, e.g., this has been demonstrated to be less than 1 percent in ten years.

Which types of magnets are the most powerful?

The most powerful types of magnets in the market today are the rare-earth magnets. Among the rare-earths, the strongest are those made of neodymium. At high temperatures (around 150 °C or more), however, samarium cobalt magnets can also be stronger than neo magnets, depending on the magnetic circuit.

What are superconducting magnets?

These are magnets of the strongest kind. They do not even require a metal core; instead, they consist of coils of wire composed of special metal alloys that turn superconductors when exposed to extremely low temperatures.

Can an existing magnet be made stronger?

When a magnet has become fully magnetized, it is said to be saturated and can no longer be strengthened. Magnets, in that case, are like buckets of water: when full, they cannot be made any fuller.

Is it possible to remagnetize a magnet that has lost its magnetic properties?

Most magnets can be re-magnetized back to their original strength, provided the material is not too hot.

How is a magnet’s strength or power defined?

The strength of a magnet is most commonly measured by the use of Gauss meters, magnetometers, or pull-testers. Gauss meters are measured in Gauss; Magnetometers in Gauss or any arbitrary unit (it is easy to compare one magnet to another); and pull-testers in pounds and kilograms, or other units of force. A sophisticated measurement of magnets is also made using Helmholtz Coils, search coils, and permeameters.

Special Gauss meters may cost up to a few thousand dollars. Integrated Magnetics stocks a few kinds of Gauss meters between 400 and 1500 apiece. Contact us if you wish to know more about them or place an order.

Suppose I have an NdFeB magnet having a Br of 12,300 Gauss. Will I be able to measure 12,300 Gauss on its surface?

No. The measurement of the Br value is done under closed-circuit conditions. A closed-circuit magnet is, however, of little use. Practically, you will find a field under 12,300 Gauss in the near vicinity of the magnetic surface. Whether the magnet contains any steel or not, the distance between the measurement point and the surface, and the size of the magnet will determine the real measure (assuming that the measurement is being done at room temperature).

In a few examples, a 1″ diameter Grade 35 neodymium magnet that is ¼” long will measure approximately 2,500 Gauss when 1/16″ away from the surface, and 2,200 Gauss when 1/8″ away from the surface.

4. Magnetic Fields and Their Behaviour

What is the strength of the magnetic field of the Earth?

The earth has a surface field strength of approximately 0.5 gauss, which can range up to 10 per cent depending on the strength of the crustal field. Between 0.85 and 0.45 is the range that is available in the world. The changes can be between 1% to 5% long lasting between a few hours and a full day, as a result of the geomagnetic storms.

What is the formula that describes the dependence of a magnetic field on distance?

The intensity of a magnetic field is decreasing more or less exponentially with distance.

The following is one illustration of the drop-off with distance of the field (in Gauss) of a samarium cobalt Grade 18-disc magnet 1/2″ long and 1″ in diameter:

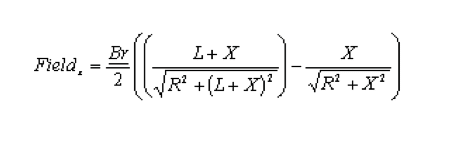

What is the field strength equation with respect to distance?

In the case of a circular magnet with radius R and length L, the field Bx in the centerline of the magnet at a distance X from the surface is given by the following expression, where Br is the remaining induction of the substance:

Field strength equation

It is also possible to use other formulae to compute the field of different other rectangular magnets and other rectangular magnets. Calculate self-field levels using our online calculators.

What can I use to block a magnetic field?

The only materials that can block a magnetic field are those attracted to a magnet. The magnetic field will be partially or even blocked in its entirety, depending on the thickness of the blocking piece.

For field mapping, Osnec magnets produce clean and well-defined magnetic fields that work well with Hall-effect sensors and visualization tools. This stable pattern makes them suitable for practical demonstrations and precision testing.

5. Magnetic Poles and Their Definitions

What are magnetic poles?

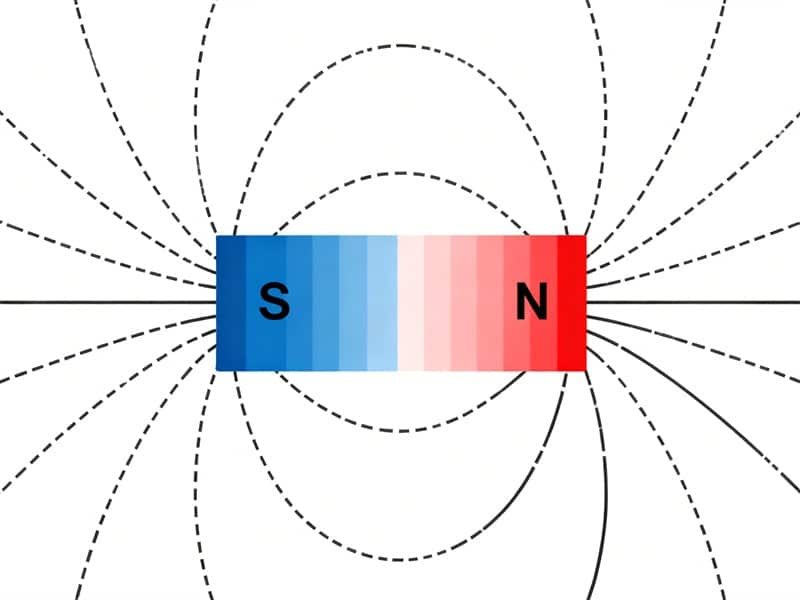

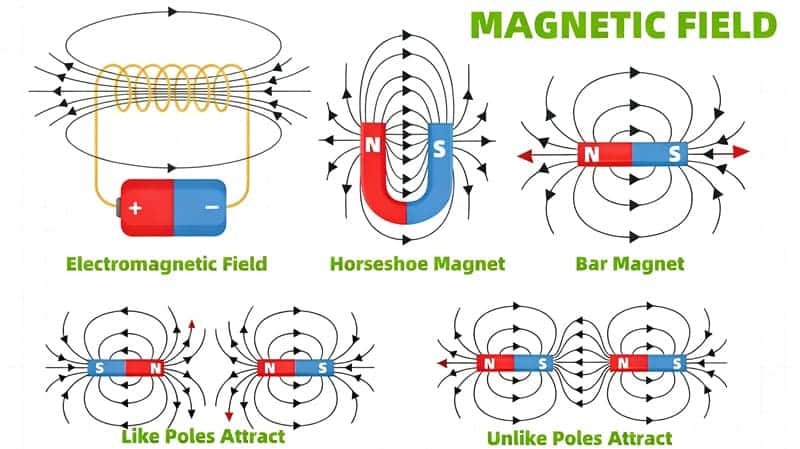

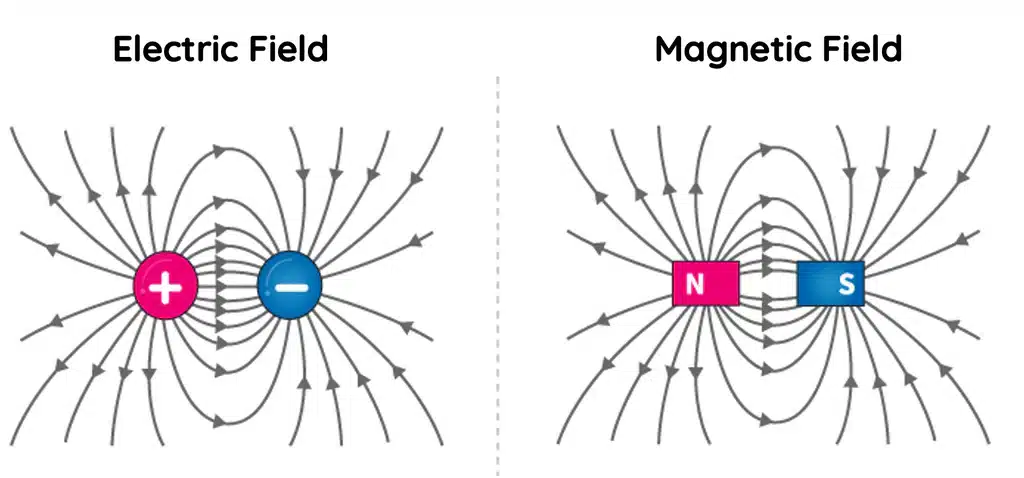

The surfaces, where the invisible lines of magnetic flux radiate out of, and the invisible lines of magnetic flux reenter the magnet, are known as magnetic poles.

What are the conventional definitions of the North and South poles?

A north pole is a pole of a magnet in which when it is left to move freely it tends to go towards the north pole of the earth. Stated differently, the north pole of a magnet will be in pursuit of the north pole of the Earth. Likewise, the south pole of the magnet follows the south pole of the Earth.

Can a specific pole be identified?

Yes, it can be marked top or the bottom of a magnet, depending upon what is specified.

How in the world do you know it is the North Pole when there is no sign of it?

You can’t tell by looking. You know by bringing a compass near the magnet. The tip of the needle, which usually moved towards the north pole of the Earth, would be directed towards the south pole of the magnet.

6. Magnetic Flux and How It Behaves

How do lines of magnetic flux behave in space?

The forces are three-dimensional as lines and surround a bar magnet on each side.

Opposites repel, and the unlike opposites attract. Two magnets with opposite poles increase the force lines, which become united on coming into contact, and the two magnets attract.

As the similar poles of a magnet are close another line of force is pushed away, and the magnet repels another.

Controlling flux density is a major challenge in rare-earth magnets. Brands like Osnec perform thermal-cycle testing and flux stability analysis to ensure their magnets maintain consistent flux even under mechanical or temperature stress.

7. Magnetic Orientation and Easy Axes

What does “direction of orientation” mean in magnets?

The majority of modern magnet materials are grained; they can be most easily maximally magnetized only in one direction. This is the easy axis, or the orientation direction, or the axis.

Un-oriented magnets (also called “Isotropic magnets”) are far weaker compared to oriented magnets, and may be made to be magnetized in any direction. Oriented magnets (or as they are sometimes called, Anisotropic magnets) are not directed everywhere – they are preferentially oriented in a direction they are supposed to be magnetized.

Whether axial, diametrical, or radial orientation is required, Osnec manufactures magnets with tightly controlled orientation tolerances. This consistency improves the overall performance of assemblies and rotational systems.

8. Key Magnetic Characteristics

Three major properties of magnets include:

Residual Induction: Assuming the symbol is Br, and in units of Gauss, this is an indication of the strength of the magnet that it could be.

Coercive Force: Since Hc is a symbol and is determined in Oersteds, this is a measure of the toughness of the task of de-magnetizing the magnet.

Maximum Energy Product: Using the various designations, BHmax, abbreviated as bhmax, the measurement unit being Gauss-Oersteds, is an indicator of the amount of magnet material needed to project a specified amount of magnetic flux.

9. Magnetic Properties of Common Materials

What are the characteristics of the common magnet materials?

The following are the three significant characteristics of magnets of some of the most frequently used types of magnets today:

How can this information be used in practice?

Given the size of the magnet, you can get an approximation of the amount of the magnetic flux various materials will project at a particular distance. This information may also be used to compare a material with another.

Example: What is the difference in flux that a neodymium grade 35 magnet will project as compared to a ceramic grade 5 of the same size at a given distance? Simply divide the Br of the neo 35 by the Br of ceramic 5 (12300/3950) to get 3.1. This means that the neo grade 35 will project 3.1 times the flux a same-size ceramic grade 5 would at a given distance.

Since the flux needed at a certain distance from the magnet is known, you can use this to determine and estimate the size of the volume of a magnet material you will need for varying magnets.

Problem: What would be the volume at which 5 magnets of ceramic would produce the same flux as a grade -35 of neodymium magnet at that distance? All that you have to do is divide BHmax of neo-35 by BHmax of ceramic-5 (35/3.6) to obtain 9.7. This implies that the amount of the ceramic-5 magnets would be 9.7 times more than that of the neo-35 magnet to produce the same flux.

10. Operating Temperatures of Magnet Materials

What are the maximum recommended operating temperatures for different magnet materials?

The highest temperature that a magnet can work with is heavily dependent on the permeance coefficient, or Pc, of the material. Pc is dependent upon the magnetic circuit on which the magnet is functioning. The greater the Pc (the more closed is the circuit), the greater the temperature within which the magnet may be used without severe demagnetism. The following table presents a range of the maximum operating temperatures of the various classes of magnet material. Special care may be required at temperatures near those given below to make sure that the magnet will not become demagnetized.

What is the highest temperature at which a magnet can still function effectively?

The magnets serve at various efficiency levels depending on the various circuits that they are involved with. The more closed the circuit is in which the magnet is operating in the more stable it will be, and the less the temperature will have an impact on the magnet.

11. Machining and Processing Magnets

Is it possible to machine magnets?

Yes, magnets can be machined. Nonetheless, the hard magnet materials are so hard to machine as opposed to the flexible or rubber-like magnet materials. There should be as much as possible, machining in the unmagnetized form, by the use of diamond tools and/or soft grinding wheels. Generally, machine-hardened magnet materials are not worth attempting to machine unless you are conversant with these special machining practices.

What factors affect the cost of machining magnets?

The factors that require the determination of the cost of the machine of the magnets include:

Quantity: The greater the quantity, the less the cost, as set-ups have to spread the set-up cost over the quantity, and special tooling is possible to machine a greater quantity.

Material: It is more expensive to machine SmCo materials; they are very brittle, and it is cheaper to machine the flexible materials due to their physical behaviors.

Shape: The shapes that are complex cost more than those that are simple.

Tolerances: The tighter the tolerances required, the further the magnets will be from the machine.

Machining magnets requires careful control to avoid cracking and chipping. Osnec produces sintered materials with cleaner edges and improved structural integrity, making post-machining processes safer and more predictable.

12. Magnetic Assemblies and Their Design

What is meant by a magnetic assembly?

Magnetic Assemblies are made up of one or more magnets, their other constituents, typically components like steel that tend to influence the functionality of the magnet.

How should magnets be mounted or assembled in my device?

In case the magnet should be attached to a machine, you can fix the magnet using some mechanical means, or you may do it using some adhesives.

Magnets are usually held by adhesives. When applying magnets on uneven surfaces then one needs an adhesive that has a large amount of body to enable conformability to the uneven surface. Hot glues are also discovered to be effective in attaching magnets to ceramics, wood, cloth, and other. In the case of magnets to be bonded to metal, superglue may be applied with high success.

Integrated Magnetics may provide flexible magnets that have adhesives already attached, so all one has to do is peel off the liner and stick the magnet onto your product. Call us, or request us to make a quote on a specialty order, or look at a large stock inventory listed online at www.magnetshop.com, where you can buy online.

It is also noted that just like any other adhesive application, the very most important thing would be to make sure all surfaces involved in bonding are clean and dry before bonding.

In assemblies, factors like adhesive choice, housing precision, and orientation balance matter. Osnec designs assemblies with these considerations in mind, ensuring stable magnetic performance and higher operational efficiency.

13. Safe Handling and Storage of Magnets

Guidelines for using and storing magnets

Magnets are to be handled with special care always! The magnets may shatter and cut people or hurt them.

Store magnets out of the magnetic pieces like floppy disks, credit cards, and computer screens.

Keep the store magnets in close packaging containers so that they do not pick up metal debris.

In case you have multiple magnets being stored, they should be in attractive places.

Due to the ease of demagnetization, alnico magnets must be kept with their keepers, which are iron or steel plates that tend to magnetize together, forming the attaching plates of the first one.

Safe handling and storage prevent magnet damage, corrosion, and accidental injury. Osnec uses packaging systems designed to limit over-attraction, moisture exposure, and impact-related stress during transport. These protective measures demonstrate the importance of proper storage practices and help users understand how environmental factors can impact long-term magnet performance.

14. Further Reading and Reference Resources

What are some recommended reference books on magnetism?

- Permanent Magnet Design Handbook, by Lester Moskowitz, a 385-page book aimed at the technical layperson.

- Permanent Magnets and their Applications, by Dr. Peter Campbell, a 203-page book aimed at the technical person.

- The Driving Force, by James Livingston, a 310- page book aimed at the non-technical reader. A very well written and interesting book on the history of magnets and some of their more exotic applications.

Request a Quote or Contact Us today and tell us how we can serve you with your specialty needs of custom magnets. Magnets are also available for purchase online at MagnetShop.com, with a large inventory.

FAQ

What materials are magnets made of?

Magnets are typically made from ferromagnetic metals and engineered alloys, mainly including neodymium-iron-boron (NdFeB), samarium cobalt (SmCo), ferrite (ceramic iron oxide), alnico (aluminum–nickel–cobalt), and flexible rubber magnets with ferrite or NdFeB powder. Osenc focuses on high-performance rare-earth neodymium magnets (NdFeB), engineered for stronger magnetic energy, precise magnetization, and application-specific coatings and shapes for industrial use.

How are magnets made naturally?

Naturally occurring magnets form when iron-rich minerals, such as magnetite, become permanently aligned with Earth’s magnetic field under geological or lightning events. These natural “lodestones” are relatively rare and have modest magnetic strength; in modern industry, Osenc instead engineers high-performance neodymium magnets (NdFeB) through controlled sintering, machining, and magnetization processes to achieve precisely defined magnetic properties and stable performance.

What happens if I break a magnet in half?

If you break a magnet in half, you do not get isolated north and south poles—each piece becomes a smaller magnet with its own north and south pole. However, mechanical shock and irregular fracture surfaces can partially demagnetize the material, reduce usable magnetic flux, and affect performance.

What is the strongest kind of magnet?

The strongest commercially available permanent magnets are sintered neodymium-iron-boron (NdFeB) rare-earth magnets, especially high grades such as N52. These magnets offer the highest (BH)max and extremely high remanence compared with ferrite, alnico, or SmCo, making them ideal for compact, high-torque, or high-force designs. As a specialized neodymium magnet manufacturer, Osenc engineers NdFeB grades, coatings, and magnetization directions to maximize magnetic strength while balancing temperature resistance and corrosion protection for different industrial applications. (Learn more about How Strong Is a Neodymium Magnet)

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.