In factories, a magnetic drum is a machine used to separate magnetic metals like iron from other materials. As the drum spins, it pulls out metal pieces using a strong magnet. This helps protect other machines and makes the final product cleaner and safer. Magnetic drums are commonly used in recycling, mining, food processing, and cement plants to remove unwanted metal parts from the production line.

Many friends will have various questions when encountering Magnetic Drum and, today we will give you a detailed introduction to what is Magnetic Drum and how it works.

It is a machine that stores data or separates things using magnets.

When you ask what is magnetic drum, you can think of two main things. First, in computers, a magnetic drum is a metal cylinder with a special magnetic coating. It spins very fast. You can use it to save data and programs. The drum has many tracks like rings around it. Read and write heads touch these tracks to put information on or take it off. This makes it a fast storage device.

Second, in factories, magnetic drums help separate metal from other stuff. The drum has a strong magnet inside. When things pass over the drum, the magnet pulls out the metal pieces.

Structure

What parts does a magnetic drum have? It has a drum shell and a magnetic system.

Let me show you the main parts:

- Drum shell: This is the outside part. It is made of strong metal like stainless steel. It spins around very fast.

- Magnetic system: This is inside the drum. It can be a permanent magnet or an electromagnet. It makes a strong magnetic field.

- Read/write heads: In computer drums, these heads touch the drum to read or write data.

- Motor: This makes the drum spin.

When you use magnetic drums in computers, the read/write heads put data on the drum as it spins. In factories, the magnetic system pulls metal pieces to the drum shell. The drum carries the metal to a special place and drops it off.

How Does Magnetic Drums Work

A magnetic drum works by spinning fast and using magnets to store or separate things.

When you look at magnetic drums, you see a big metal cylinder. This cylinder spins very fast. The outside of the drum has a special magnetic layer. In computers, this layer helps you save and get back data. In factories, the drum uses a strong magnetic field to pull metal pieces away from other things.

Here is how magnetic drums work in two ways:

- In computers

- In factories

In computers:

- The drum spins.

- The magnetic layer holds tiny spots. Each spot can be a 1 or a 0.

- Read/write heads touch the drum and change these spots to save data.

- When you want to retrieve data, the heads read the spots as the drum spins.

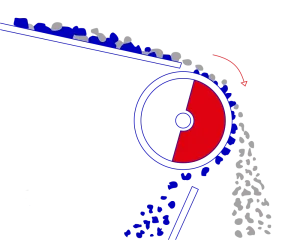

In factories

- The drum has a strong magnet inside.

- When you put a mix of things on the drum, the magnet pulls metal pieces to the drum.

- The drum carries the metal away from the rest.

- Airflow helps spread out the pieces, so the magnet can work better.

Magnetic Drum Separators

You use magnetic drum separators in factories to separate metal from other things.

These machines have a drum with strong magnets inside. When you put a mix of things on the drum, the magnet pulls out the metal. The rest falls off the drum. You can use different magnets for different jobs.

Here is a table to show the types of magnets you can find in magnetic drum separators:

| Magnet Type | Magnetic Field Strength | What It Does |

|---|---|---|

| Ferrite Magnet | 100 to 600 mT | Good for big metal pieces and easy separation |

| Rare Earth Magnet | Up to 2.2 Tesla | Best for tiny or weakly magnetic particles |

| Electromagnetic | Variable | You can change the strength, but it is harder work |

- Ferrite magnets are good for simple jobs.

- Rare earth magnets help you get very pure metal, even small pieces.

- Some separators use a criss-cross magnet design for better coverage.

- Permanent magnets make the machine easy to use and clean.

🧲 Tip: If you want to separate fine or weakly magnetic particles, you should use rare earth magnets. They make the magnetic separator work better and faster.

Applications of Magnetic Drum

You use magnetic drums in factories to separate metal from other things.

I see that magnetic drum separators help you clean up big piles of stuff. You put the mix on the drum. The drum spins and the magnet inside pulls out the iron or steel. The rest falls away. This makes your work faster and safer.

Here is how you use magnetic drum separators in factories:

- You put the mix of things on the drum.

- The drum spins and the magnet grabs the metal.

- The metal sticks to the drum.

- The drum moves the metal to a special place.

- The clean stuff falls off.

🏭 Note: You can use magnetic drum separators in recycling, mining, food, and building. They help you get pure products and protect your machines.

Magnetic Drum Separators

You can find magnetic drum separators in many industries to make work easy and safe.

I want to show you where you use them:

| Industry | What You Do With Magnetic Drum Separators |

|---|---|

| Mining and Mineral Processing | Get iron from rocks and ores. |

| Recycling | Take out iron and steel from trash and old things. |

| Food Processing | Remove metal bits from grains and powders. |

| Construction & Demolition | Clean metal from building waste. |

| Wood Processing | Pull out metal from wood chips and sawdust. |

| Pulp & Paper | Keep metal out of paper and protect machines. |

| Cement | Remove iron from cement mix. |

| Automotive and Manufacturing | Stop metal from hurting machines. |

- In recycling, you use magnetic drum separators to get iron and steel from trash.

- In mining, you use them to find iron in rocks.

- In food factories, you use them to keep food safe from metal.

Advantages of Magnetic Drums

You find special features in magnetic drums that help you in many jobs.

I think magnetic drums are different from other machines. They use a spinning drum and a magnet inside. The design lets you pull out metal from a mix of things. Some drums use special circuits to make the magnetic field stronger and more even. You can pick drums with different pole shapes for different jobs. Some drums work best with powder, others with big metal pieces.

- You can use different pole designs (axial or radial) for your needs.

- Some drums have heavy-duty shells for tough jobs.

- You do not need electricity for permanent magnets.

- The drum can work in recycling, mining, or food factories.

FAQ

What is the main job of a magnetic drum?

A magnetic drum stores data or separates metal.

You can use it in old computers to save programs. You also see it in factories to pull out metal from other things. The drum spins fast and uses magnets.

How do you clean a magnetic drum separator?

You clean it by stopping the machine and wiping the drum.

I use a soft cloth to wipe dust and metal bits. I check the drum for damage. I make sure the magnet still works well. 🧹

Can you use a magnetic drum as a permanent separator?

Yes, you can use it as a permanent separator.

I see that some drums use strong magnets that never lose power. You do not need electricity for these. They work all day in factories. 🏭

Why did computers stop using magnetic drums?

Computers stopped using them because new memory is faster and smaller.

I see that magnetic core memory and hard drives replaced drums. You can save more data and get it quicker with new memory.

Where do you see magnetic drum separators today?

You see them in recycling, mining, and food factories.

I find them in places where you need to pull out metal. They help keep products clean and machines safe. ♻️

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.