neodymium magnets 40×20 n52

Wholesale Neodymium Magnets 40×20 N52 For Sale

N52 neodymium magnets (40×20 mm) are industrial NdFeB with high magnetic energy product. Under GB/T 13560-2017 (Sintered NdFeB), N52 typically achieves (BH) of 48–52 MGOe and remanence (Br) about 14.2–14.7 kG. Because there’s no unified global standard, some suppliers describe comparable grades using commercial labels like “52 MGOe class,” so selection should reference temperature rating and test reports and coating.

Specification of Neodymium Magnets 40×20 N52

| Parameter | Specification |

|---|---|

| Size | Diameter 40 mm × Thickness 20 mm |

| Material | Sintered NdFeB (Neodymium-Iron-Boron) |

| Grade | N52 |

| Shape | Disc (cylindrical) |

| Magnetization | Through thickness (axially magnetized) |

| Coating | Ni-Cu-Ni (nickel), other finishes optional |

| Tolerance | Typically ±0.05–0.10 mm (supplier-dependent) |

| Max Operating Temperature | ~80 °C for “N” grade (higher with M/H/SH variants) |

| Polarity | North/South on the two flat faces |

| Safety Note | Strong and brittle; handle with care and keep away from pacemakers/electronics |

| Comparison of N54 vs. N35 to N52 Neodymium Magnets | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Remanence (Br) | Residual Coercivity (Hcb) | Intrinsic Coercivity(Hcj) | BH max | ||||

| kGs | T | kOe | kA/m | kOe | kA/m | MGOe | KJ/m³ | |

| N35 | 11.7-12.2 | 1.17-1.22 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 |

| N38 | 12.2-12.5 | 1.22-1.25 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 |

| N40 | 12.5-12.8 | 1.25-1.28 | ≥11.4 | ≥907 | ≥12 | ≥955 | 38-41 | 302-326 |

| N42 | 12.8-13.2 | 1.28-1.32 | ≥11.5 | ≥915 | ≥12 | ≥955 | 40-43 | 318-342 |

| N45 | 13.2-13.8 | 1.32-1.38 | ≥11.6 | ≥923 | ≥12 | ≥955 | 43-46 | 342-366 |

| N48 | 13.8-14.2 | 1.38-1.42 | ≥11.6 | ≥923 | ≥12 | ≥955 | 45-49 | 358-390 |

| N50 | 14.0-14.5 | 1.40-1.45 | ≥12.0 | ≥955 | ≥12 | ≥955 | 47-51 | 374-406 |

| N52 | 14.2-14.6 | 1.42-1.46 | ≥12.0 | ≥955 | ≥12 | ≥955 | 49-53 | 390-422 |

| N54 | 14.5-14.9 | 1.45-1.49 | ≥10.5 | ≥876 | ≥11 | ≥955 | 51-55 | 406-438 |

Get the reliable Neodymium Magnets 40×20 N52 you need to complete your project with our help.

Dedicated to custom magnet production.

Characteristics of Neodymium Magnets 40×20 N52

Advantages ------

Surface Finish / Coating:

Standard finish is Ni–Cu–Ni (nickel), with optional coatings such as zinc, black/color epoxy, gold (Ni–Cu–Ni–Au), silver (Ni–Cu–Ni–Ag), chrome, parylene, or phosphating; the choice affects corrosion resistance, wear, and appearance, so pick nickel for general use, epoxy for extra corrosion protection, and noble finishes when aesthetics or additional barrier layers are required.

Tolerance:

Typical manufacturing tolerance for a 40×20 mm disc is about ±0.05–0.10 mm on diameter and thickness for ground parts; commodity listings can be looser (±0.10–0.20 mm or ~±1%), while tighter control such as ±0.02–0.05 mm is available on request with additional grinding, cost, and lead time.

Magnetization Direction:

The most common is axial magnetization through the thickness, placing the north and south poles on the two flat faces; diametrical magnetization is less common for solid discs, and multi-pole patterns usually apply to rings or specialized applications, so specify axial unless your fixture explicitly requires another orientation.

Pull Force / Holding Force:

Holding force depends heavily on the test setup—steel grade and thickness, air gap, surface finish, and whether the load is tensile or shear—so published values vary; as a rough benchmark, a thinner N52 block of similar face area (40×20×5 mm) can show ~15 kg pull under ideal conditions, and a 20 mm-thick disc will be substantially higher (often in the tens of kilograms) when tested against thick, low-carbon steel with near-zero gap—always request the supplier’s method and fixture details.

Max Operating Temperature:

For N52 (“N” series) the recommended maximum operating temperature is ~80 °C; higher-temperature grades (M ≈100 °C, H ≈120 °C, SH ≈150 °C, UH ≈180 °C, EH ≈200 °C, AH ≈220 °C) increase heat tolerance at the cost of some peak magnetic performance, so select the temperature rating according to your application’s thermal profile.

Applications of Neodymium Magnets 40×20 N52

Magnetic couplings

In pumps and mixers, N52 magnets transmit torque through barriers without contact, prevent leaks, isolate contaminants, tolerate misalignment, and significantly reduce maintenance in industrial systems.

Magnetic separators

Integrate N52 discs into housings or bars to capture ferrous fines from powders, grains, or liquids, protecting downstream equipment, improving purity, and lowering maintenance costs.

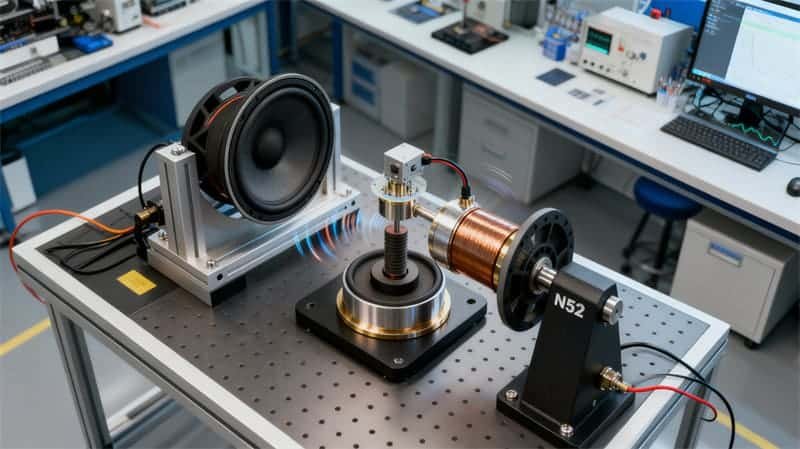

Audio & vibration experiments

Build speaker motors, shakers, and damping rigs with N52 discs to generate strong, stable fields for precise excitation, resonance studies, materials testing, and prototype validation.

Medical laboratory apparatus

Use N52 discs for configurable clamps, tubing retainers, and instrument mounts on steel frames, enabling reconfiguration without drilling while maintaining cleanliness, sterility, and gentle attachment.

Robotics & automation

Create quick-swap end effectors, magnetic grippers, and targets with N52 discs, simplifying tool changeovers, steel part handling, fixture referencing, and fail-safe retention in robotic assembly.

Heavy-duty fixturing & clamps

Form high-holding-force bases for welding jigs, CNC workholding, and assembly stations; N52 discs provide precise positioning on thick low-carbon steel, improving throughput and safety significantly.

Safety & Handling guidelines for an N52 40×20 mm magnet

Pinch hazards: Keep fingers clear; approach steel slowly using spacers (cardboard/plastic). Wear cut-resistant gloves and eye protection. Separate by sliding, not prying.

Brittleness: Sintered NdFeB chips/shatters if slammed together or dropped. Avoid impacts and edge-to-edge contact; use bumpers or shims.

Keep distance from devices: Maintain ≥30 cm from pacemakers/implants. Keep away from phones, hard drives, magnetic cards, compasses, and precision instruments.

Temperature limits: Standard N52 is rated to ~80 °C operating; above this risk demagnetization. Use M/H/SH/UH/EH/AH grades for hotter environments. (Related: grades of magnets)

Corrosion protection: Nickel coatings scratch; in humid/salt environments prefer epoxy/parylene. Keep dry; replace if plating is damaged.

Shear loads: Advertised pull is mostly normal (tensile). Shear holding is much lower—add mechanical stops, pins, or anti-slip features.

Mounting practice: Use thick, low-carbon steel backers; chamfer edges. Provide threaded holes or pry notches for safe removal.

Storage & transport: Use keepers/shorting plates and non-magnetic spacers. Isolate from ferromagnetic cargo/electronics; follow IATA magnetic leakage rules.

No onsite machining: Cutting/grinding generates conductive, flammable dust and heat that causes demagnetization—avoid; source to final size instead.

Children & pets: Strong magnets are a choking/ingestion hazard; keep out of reach at all times.

Cleaning: Wipe with a soft dry cloth; avoid harsh chemicals. Remove swarf promptly to prevent bridging and unexpected attraction.

SOP & training: Define safe distances, PPE, separation tools, and emergency steps. Train staff before handling large N52 magnets.

Customization options for an N52 40×20 mm magnet

Dimensions & tolerances: Diameter/thickness changes; tighter tolerances (e.g., ±0.02–0.05 mm) with precision grinding.

Grade & temperature rating: Swap N52 for M/H/SH/UH/EH/AH series to meet higher operating temperatures.

Magnetization direction: Axial (through thickness) by default; diametrical or multi-pole patterns (typically for rings) on request.

Coating / finish: Ni-Cu-Ni standard; options include Zn, epoxy (black/colored), gold/silver, chrome, parylene, or phosphate for corrosion/appearance needs.

Chamfers & edge treatment: Edge break, corner radius, or protective bumpers to reduce chipping and ease assembly.

Holes & countersinks (pre-sinter design): Center hole or countersunk hole for fasteners (must be designed into the press; no post-machining).

Assemblies / pot magnets: Overmolded or steel-cup (pot) housings to boost holding force and add mechanical mounting features.

Adhesive backing: Factory-applied PSA (e.g., 3M VHB) with pull tab for tool-free mounting on clean surfaces.

Polarity & marking: Orientation marks, laser engraving, color dots, or serialized IDs for assembly control and traceability.

Matching / pairing: Gauss-matched sets, flux-density binning, and polarity-paired kits for couplings or sensor applications.

Inspection & documentation: AQL sampling plans, material certs, RoHS/REACH compliance, pull-test reports, BH curve data on request.

Packaging & logistics: Keeper plates/spacers, corrosion-control packaging (desiccants, vacuum bags), custom labels, and export-compliant cartons.

How to Choose Neodymium Magnets 40×20 N52 Manufacturer

Verify material & grade — request BH curve, Br/Hcj, RoHS/REACH certificates, and third-party tests. Osenc provides full magnet curves and batch traceability.

Precision & magnetization — demand tolerances ±0.05–0.10 mm and axial magnetization. Confirm polarity, face flatness, matching pairs; audit grinding capability and gauges.

Coatings by environment — Ni-Cu-Ni general, epoxy marine, parylene medical. Osenc offers salt-spray testing, plating thickness reports, and accelerated corrosion data.

Quality system & testing — ISO 9001, AQL sampling, pull-test method, demagnetization curve retention after heat. Require PPAP, COA, and retained samples policy.

Capacity & support — check capacity, lead time, MOQ, engineering help. Osenc supplies DFM advice, magnet–steel assemblies, keepered packaging, and export-compliant IATA-safe shipments.

We know that it is not easy to find a reliable Neodymium Magnets 40×20 N52 supplier. Therefore, we focus on building a strong and trusting relationship with our customers, providing reliable magnetic products and unparalleled customer support. Let us be your trusted supplier – contact us today to discuss your needs and we’ll guide you to the perfect Neodymium Magnets 40×20 N52 for your project

Let‘s Realize Your Grand Plan Together

- [email protected]

- 0086 139 2737 7121

- Changping, Dongguan, Guangdong 523000, China

- We will respond to you within five minutes.