Last Updated on

March 8th, 2024 03:30 pm

Benefits of Demagnetization in Manufacturing

Demagnetization

It is a critical aspect of magnetism management in various industries. Understanding how magnets behave before and after magnetization sheds light on the importance of demagnetizer (also name degausser) in manufacturing processes.

Before magnets undergo the magnetization process, they do not exhibit any magnetic properties. This fundamental principle underscores the necessity of demagnetizer, which serve to remove unintended magnetism from manufactured products. In the absence of demagnetization, products may encounter assembly issues and functional limitations due to residual magnetism.

The significance of demagnetizing machines becomes evident when considering magnetic field measurements. These machines are equipped with precise measurement capabilities, allowing manufacturers to gauge the strength of magnetic fields within their products. With alarm systems set to specific thresholds, they ensure that magnetism remains within acceptable limits, as per industry standards.

Process

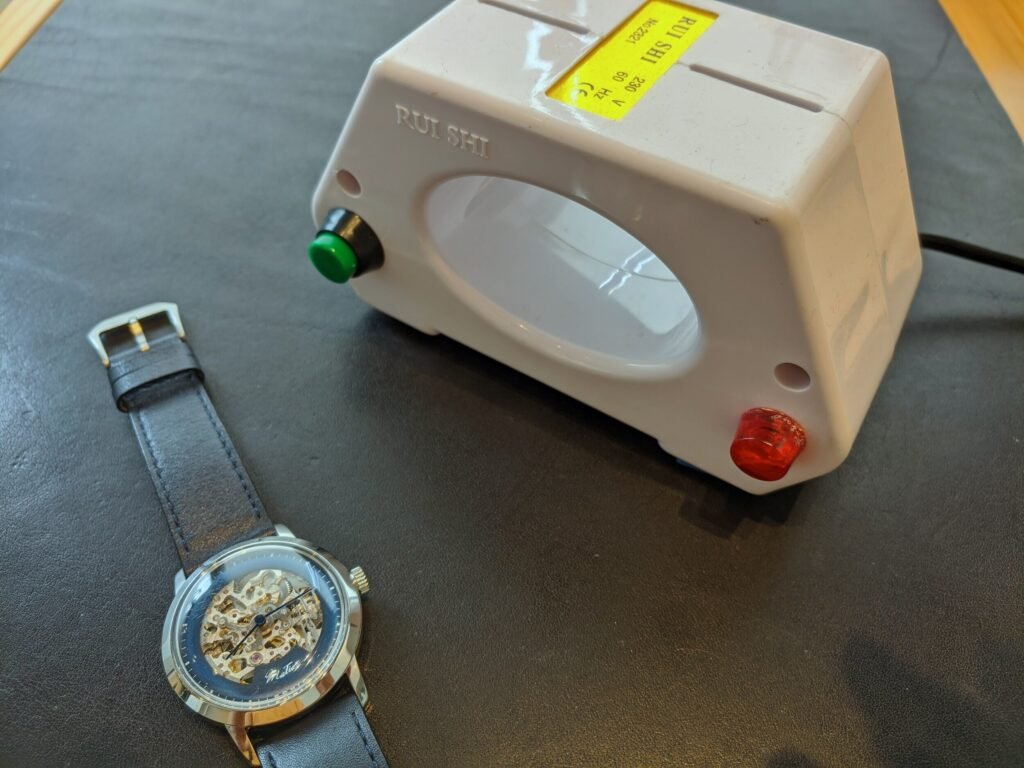

itself is straightforward yet crucial. Just put the product on the surface of the demagnetizer or through it. (It depend on what demagnetizer you buy).

By subjecting products to demagnetizing machines, manufacturers effectively neutralize any unintended magnetism present. This process is exemplified by a subtle yet audible hum as the machine works to eradicate magnetism. Subsequent measurements confirm the success of the demagnetization process, with magnetic field readings falling within acceptable ranges.

Benefit

It extend beyond mere magnetism management. By preventing magnets from sticking together and adversely affecting electroplating quality, demagnetization enhances product quality and functionality. In manufacturing facilities, demagnetizing machines play a pivotal role in quality assurance, ensuring that products meet stringent standards before reaching consumers.

Conclusion

Demagnetization is an essential aspect of modern manufacturing processes. By investing in demagnetizing machines , manufacturers can mitigate magnet-related issues and deliver high-quality products to consumers. The role of demagnetizer in maintaining product integrity and functionality cannot be overstated, making them indispensable tools in today’s manufacturing landscape.