Custom Shuttering Magnets & Precast Concrete Magnet Wholesale

Key benefits at a glance

- Holding force range from 450 kg to 3000 kg, ensures a secure hold on even large formwork panels.

- Suitable for steel, wood, plywood and aluminium side forms — Shuttering magnets offer an ideal range of applications across common rail and profile systems.

- On/off push-button operation – no drilling or welding needed

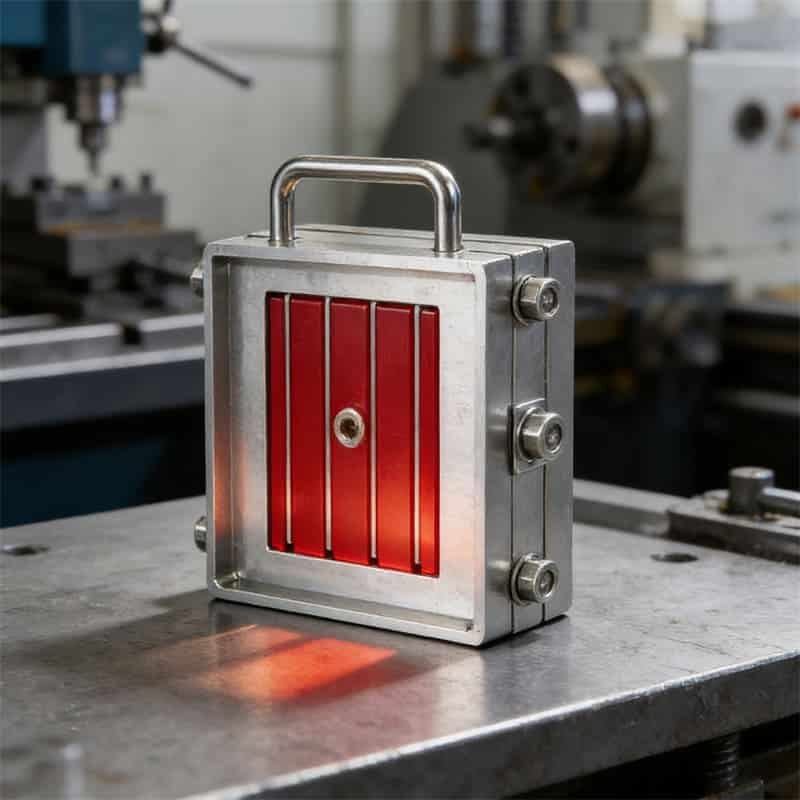

- Compact magnet box with high holding force vs. weight

- Fully customizable sizes, threads, coatings and adapter systems

Looking for a custom precast concrete magnet solution?

Contact Osenc to discuss your drawings, production line and holding force requirements.

Table of Contents

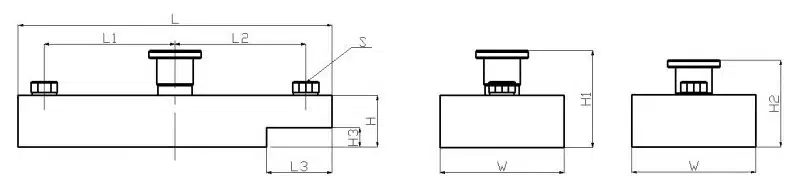

Shutter magnet specification

| Model | Dimension (mm) | Cover material | Net weight (kg) | Attractive forece (kg) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | L1 | L2 | L3 | H1 | H2 | H3 | S | ||||

| OSENC600 | 210 | 60 | 40 | 92.5 | 71.5 | 40 | 74 | 65 | – | M12 | S304 | 1.9 | 600 |

| OSENC800 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 2.8 | 800 |

| OSENC900 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 3.0 | 900 |

| OSENC1000A | 200 | 98 | 40 | 99.5 | 67.5 | 50 | 75 | 65 | 10 | M12 | S304 | 2.8 | 1000 |

| OSENC1000B | 240 | 68 | 54 | 90 | 90 | – | 88 | 79 | – | M12 | Q235 | 3.2 | 1000 |

| OSENC1800A | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | S304 | 5.7 | 1800 |

| OSENC1800B | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | Q235 | 6.3 | 1800 |

| OSENC2100A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.3 | 2100 |

| OSENC2100B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.4 | 2100 |

| OSENC2400A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.5 | 2400 |

| OSENC2400B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.6 | 2400 |

| OSENC3000 | 320 | 160 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 10.6 | 3000 |

Applications in Precast Concrete Production

Osenc precast shuttering magnets are used wherever formwork must be positioned quickly and held securely on a steel surface.

Typical applications include:

Precast wall panels – solid walls, sandwich walls, façade and cladding panels

Floor and roof slabs – hollow core slabs, solid slabs and balcony elements

Beams and columns – structural precast components for buildings and infrastructure

Modular elements – bathroom pods, stair elements, elevator shafts, utility modules

Tilting tables and fixed beds – for flat element production

Battery molds – vertical production of wall elements

Whether you work with standard panels or Complex and /or frequently changing geometries, Osenc shuttering magnets provide a reusable and non-destructive way to fix side forms to steel casting beds.

Osenc Precast Shuttering Magnet Range — Shuttering Magnets for Pre-cast concrete formwork

Osenc offers a complete range of standard precast concrete magnets / shuttering magnets that includes magnets of different types and sizes to match your element types and production lines.

- Holding force options from 450 kg up to 3000 kg — we supply shuttering magnets with various adhesive power to suit light rails through heavy-duty profiles.

- Compact box sizes to save space on crowded casting tables

- Housing materials: stainless steel (S304) or carbon steel (Q235)

- Integrated threaded inserts (e.g. M12 / M16 / M20) for adapter connection

Typical use by holding force

- 450–900 kg – small elements, light side rails, narrow beams

- 1000–1800 kg – standard wall and slab elements, medium-height side forms

- 2100–3000 kg – tall or heavy side forms, thick solid walls, sandwich panels, strong vibration environments

Standard models can be combined with custom adapters, clamps or profiles to match your existing formwork system. For special projects, Osenc can design fully customized magnet box sizes and force levels.

Get the reliable Shuttering magnets you need to complete your project with our help.

Key Features & Benefits of Osenc Shuttering / Precast Concrete Magnets

High Holding Force in a Compact Design

Osenc shuttering magnets use high-performance neodymium (NdFeB) cores and optimized magnetic circuits to achieve very strong holding forces in a compact box — an innovative magnetic solution to profiling the precast concrete formwork!

- Maximize usable space on the casting table

- Secure heavy or tall side forms with fewer magnets

- Keep handling weights manageable for your operators

Switchable On/Off Operation

Each magnet box features a push-button on/off mechanism:

- OFF position: magnetic field is largely contained inside the housing → easy to slide and position

- ON position: pressing the button engages the magnetic core against the steel bed → full holding force

This simple operation:

Saves time during setup and stripping

Reduces worker fatigue

Minimizes damage compared to hammering mechanical fasteners

Compatible with Wood, Steel and Aluminium Formwork

Thanks to integrated threaded holes and custom adapter solutions, the same magnet platform can be used with:

Steel side rails

Wooden or plywood form boards

Aluminium formwork profiles

You can standardize on one magnet family, and adapt it to different formwork systems through adapter plates, clamps or frames.

No Drilling or Welding of Casting Beds

Traditional fixing methods require drilling, bolting or welding on the steel table, which:

Damages the expensive casting surface

Increases long-term maintenance costs

Slows down changeovers between element types

Shuttering magnets offer a non-destructive fixing method – the surface remains intact, and formwork can be rearranged quickly without hot work. In many plants, They have completely revolutionized the construction workflow by making changeovers faster and cleaner.

Long Service Life & Easy Maintenance

Osenc precast concrete magnets are designed for:

Long service life in demanding factory environments

Simple maintenance – mainly cleaning and basic protection against corrosion

Repeated use across many production cycles, reducing lifetime cost per element

Customization Options

Every precast plant is different. Osenc provides fully customizable precast shuttering magnet solutions to match your processes.

You can customize:

Holding force

From around 450 kg up to 3000 kg or more, depending on element size, form height and vibration intensity.

Dimensions

Box length, width and height to match your side rail system and available table space.

Threaded connections & adapters

Thread sizes such as M12, M16, M18, M20. Custom adapters for wooden boards, aluminium profiles, steel beams, top supports and corner details — used to fasten the shuttering box magnet with precast side mold tightly for better shear resistance during pouring and vibration.

Magnet material & temperature rating

Neodymium grades selected according to your operating temperature and production environment to ensure stable performance.

Surface treatment

Options such as zinc plating, nickel plating (Ni-Cu-Ni), phosphating, epoxy coating, nano-coating and others to enhance corrosion resistance and durability.

Share your drawings, side rail profiles and casting table details, and Osenc will recommend or design the most suitable shuttering magnet configuration for your plant.

How Osenc Shuttering Magnets Work

Built as shuttering magnets designed for precast concrete, these units are part of our Magnetic shuttering solutions for precast concrete formworks to help plants standardize setup and improve repeatability.

Magnetic Circuit Principle

Inside each Precast Concrete Magnet / Shuttering Magnet, an array of sintered neodymium magnets is bonded to a steel block and enclosed by a steel housing. Together with the steel casting bed, they form a closed magnetic circuit:

When activated, magnetic flux is directed through the contact surface into the table, creating a very strong holding force.

When deactivated, a controlled air gap reduces the effective flux at the contact surface, and the magnet can be moved easily.

Step-by-Step Operation

Positioning

Place the shuttering magnet on the clean steel casting bed.

Make sure both the magnet base and table surface are free of concrete residues or metal chips – even small air gaps will reduce holding force.

Aligning formwork

Attach the side rail (steel, wood, plywood, aluminium) via threaded adapters, clamps or frames.

Slide the magnet box and side form into the desired position.

Activating the magnet

Press the button / switch on top of the magnet.

The magnet engages with the table and securely holds the side form, even during intensive vibration.

Concrete pouring and vibration

Pour and compact concrete as usual.

The strong holding force and increased shear resistance (especially with top adapters) keep the side forms in place.

Releasing and cleaning

Use a lever tool/crowbar to pull up the button and switch the magnet off.

Remove the magnet from the table, clean off any concrete or debris and, if needed, apply a light anti-corrosion treatment before storage.

Quality Control & Packaging

Osenc implements strict quality control throughout the production of precast concrete magnets:

Material control

- Careful selection of neodymium magnet grades and steel housing materials

- Inspection of incoming steel, springs, threaded studs and fasteners

Assembly & performance testing

- Precise assembly of magnet cores and housings

- Holding force (tensile) testing of each batch according to specified pull ratings

- Functional tests of the on/off button and spring mechanism

Surface protection

- Appropriate coatings (zinc, nickel, epoxy, etc.) to improve corrosion resistance and service life

Packaging & transport

- Protective anti-collision and waterproof packaging

- Magnetic shielding to comply with air and rail transport regulations

- Packing solutions optimized for sea, air or rail shipment

This ensures that your shuttering magnets arrive ready for use and maintain consistent performance in daily production.

Why Choose Osenc for Shuttering / Precast Concrete Magnets?

Magnetic engineering know-how

- Over two decades of experience in magnetic technology for precast concrete formwork.

Full customization capability

- From standard box magnets to special long strip magnets, corner magnets and adapter systems – all tailored to your production line.

Consistent quality & reliability

- Controlled materials, tested holding forces and robust housings designed for real precast factory conditions.

Global project experience

- Custom shuttering magnet solutions delivered to precast plants in multiple countries, supporting both new lines and retrofits.

Supportive service

- Technical support on magnet selection, application design and transportation, from first inquiry to after-sales.

FAQ About Precast Shuttering Magnets

When Using shuttering magnets in your construction projects, it helps to understand selection, adapters, and safety practices for Shuttering magnets for precast concrete lines.

Precast concrete magnets, often referred to as shuttering magnets, magnet boxes or button magnets, are compact permanent magnet assemblies engineered to hold formwork side rails firmly on a steel casting bed — Shuttering magnets are specialized magnetic components built for repeatable positioning and clamping. Instead of drilling, bolting or welding the formwork table, a shuttering magnet uses a high-grade neodymium magnetic core inside a robust steel housing to generate very strong holding forces and enable you to quickly create a temporary setup for different element runs.

By integrating a switchable on/off mechanism, precast shuttering magnets allow operators to:

Quickly position and reposition side forms

Secure the formwork during concrete pouring and vibration

Release the magnets and strip the formwork for the next cycle

This makes them one of the most important accessories in modern industrial precast concrete production.

Yes. In practice, both terms refer to the same type of product – a switchable magnet box used to fix formwork side rails on steel casting beds. Other common names are magnetic formwork systems, magnet boxes or button magnets.

The required holding force depends on several factors: element size, wall/slab thickness, formwork height, vibration level and safety margin. As a rough guide, heavier elements, taller side forms and stronger vibration require higher pull forces (e.g. 1800–3000 kg). Share your element data and side rail details with Osenc and we will recommend a suitable magnet size and force.

Yes. Osenc can customize dimensions, threaded holes, adapters and surface treatments so that the magnet boxes fit your current side rails and production line. We can also design special long strip magnets or corner magnets if needed.

Lead times depend on the model and customization level. Standard sizes are usually available faster, while fully customized magnets require additional design and tooling time. Let us know your project schedule and target delivery date, and we will confirm a suitable lead time.

Let‘s Realize Your Grand Plan Together

- [email protected]

- 0086 139 2737 7121

- Changping, Dongguan, Guangdong 523000, China

- We will respond to you within five minutes.