Last Updated on

February 18th, 2023 04:29 pm

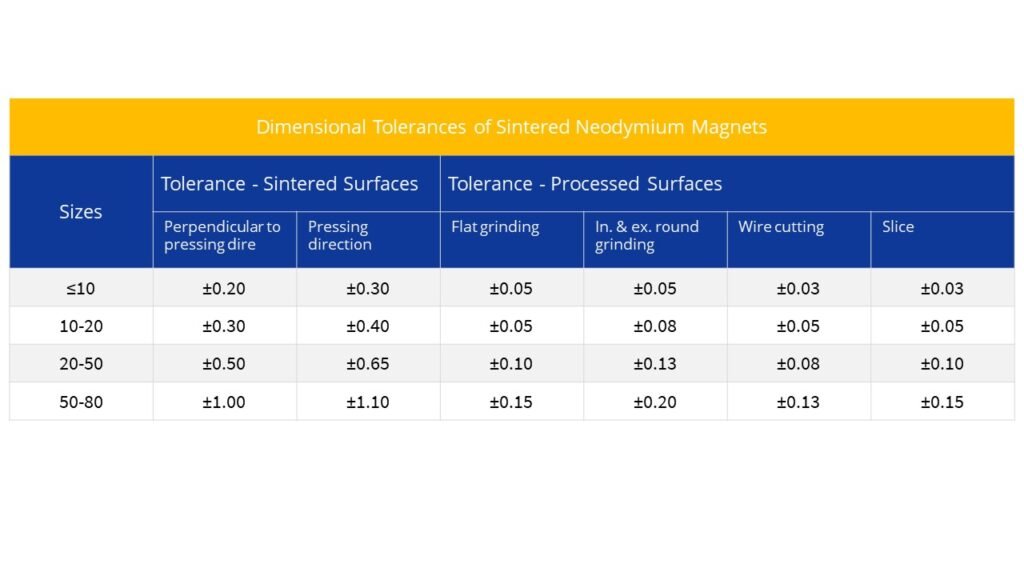

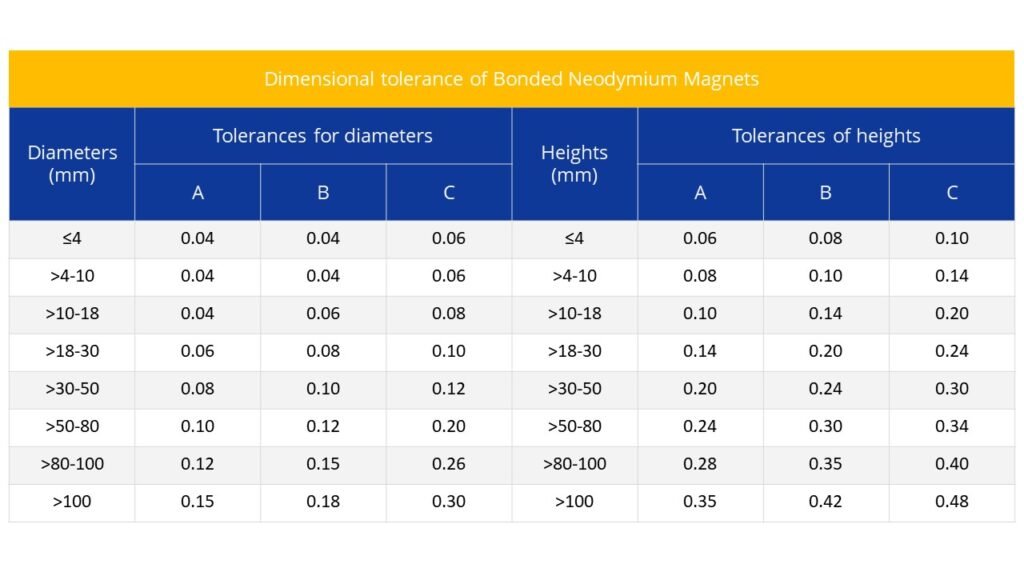

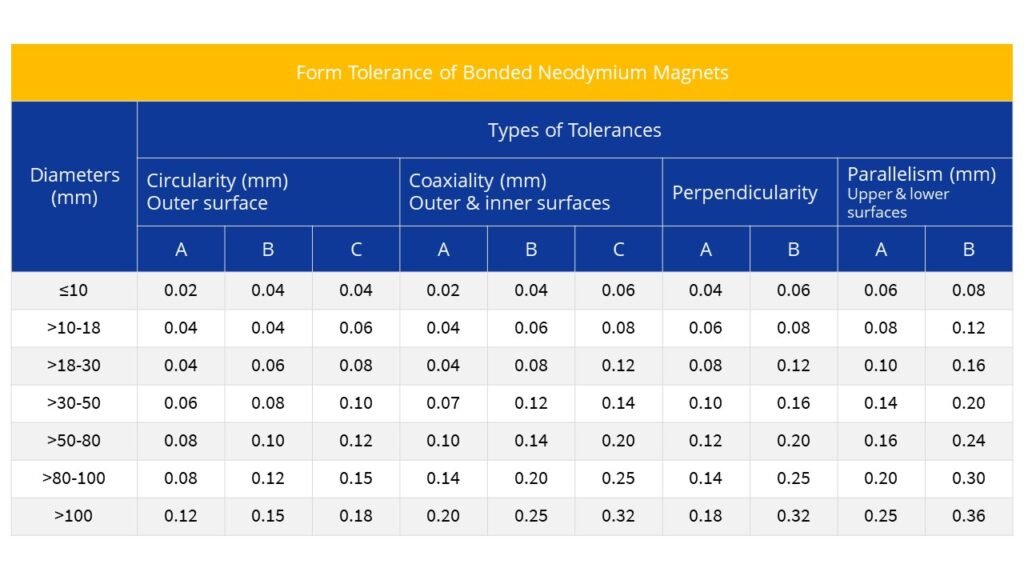

Magnet Tolerance is one of the important factors in neodymium magnet purchasing. It includes dimensional tolerance and form tolerance.

Neodymium magnets are important units for manufacturing many application. They are critical components for high-tech products like motors, horns, testing instruments, etc. That is why buyers have certain requirements for the dimensional tolerance and form tolerance of neodymium magnets.

If neodymium magnets have incorrect dimensions, they does not work properly with other components on the finished products, which can lead to refunds and returns.

Osenc is a custom neodymium magnet manufacturer with intensive experience about how to assure the correct sizes for magnets. We have prepared 2 tables showing the dimensional tolerance and form tolerance of neodymium magnets. They will be helpful for you to evaluate the quality of magnets.

Note:

The dimensional tolerance and form tolerance of bonded neodymium magnets can vary depending on their shapes and applications. Take the ring neodymium magnets for example, even the same size and form can have 3 different tolerances: A, B, and C.

The workpiece assemblies are safe and reliable only when both the dimensional tolerance and form tolerance of magnets are qualified.

Some neodymium magnet suppliers don’t pay attention to the form tolerances of magnets, and this makes the parts can be assembled, which leads to complaints, refunds, and return requests from customers.

Neodymium magnet suppliers usually use 2 measuring tools as quality standards.

Micrometer: It can only measure the dimensions of magnets, but not the forms.

Through stop gauge: It is able to measure both the dimensional tolerances and form tolerances of magnets.

One typical case is that the magnets can pass the tests of a micrometer for dimensional tolerances. However, they fail the form tolerance tests by the through stop gauge.

This is because even if dimensions are within the tolerances but the forms are disqualified, the magnets will still can’t be assembled.

Neodymium magnets are small and light. This application advantage becomes its difficulty in the quality inspections. They have large quantities and small sizes, so usually they require manual inspections, which are slower and less accurate than automatic machines.

At this moment, most neodymium manufacturers rely on manual inspections of the quality management department. The disadvantages of manual inspection are slow inspection speed and high labor costs. This is also an important reason why custom neodymium magnets are more expensive than most other magnets.

In order to increase efficiency and also reduce labor costs, more and more neodymium manufacturers begin using automatic inspection machines.

And at Osenc, it is one of our most important plans to make the best use of automatic technologies to improve accuracy and efficiency during quality inspections. And thanks to these new technologies, we can proudly say we can offer a tolerance of +/- 0.005 mm, which is a higher precision especially good for micro magnets.