One of the strongest Neodymium (Neo) magnets in the market today includes N52, N54, and N55. But which of them is really the most powerful? In addition to the strength, other parameters such as heat resistance and magnetic field range are important.

This article provides a comparison of N52, N54, and N55 magnets, their differences in terms of performance and use. We will also discuss what makes the best magnet in general, to enable you to select the correct magnet to use.

What is N52 magnet?

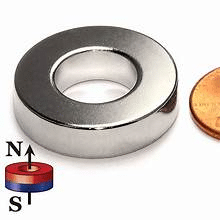

A N52 magnet is a neodymium magnet with a maximum energy product (BH) Max of 52 MGOe (Mega-Gauss Oersteds). The N52 is a name given to its strength, which makes it the strongest neodymium magnet in the market.

Neodymium magnets are a product of neodymium mixed with iron and boron, thus making them have amazing magnetic strength. Other grades too, such as N35, N38, N42, N45 and N48, the higher the number, the stronger the magnet. N52 magnets are also relatively costly compared to low-grade ones because N52 magnets are the strongest and therefore expensive.

Osencmag is an international manufacturer of high-grade N52 neodymium magnets manufactured under hi-fi sintering and fine machining techniques. N52 magnets are produced in various shapes by their factory partners so that customers can select the geometry needed in high-performance projects, such as discs, blocks, rings, cylinders, spheres, countersunk discs, and arc-shaped motor parts. Each N52 magnet of Osencmag is carefully tested in terms of magnetic field, dimensional and coating durability to maintain the same flux density, precision tolerances and stability in harsh conditions like robotics, industrial motors, consumer electronics, automation devices and magnetic coupling assemblies.

What is the N54 Magnet?

The strongest N series neodymium magnets, which can be produced in large quantities, are N54 magnets. But even now, N52 magnets are commonly viewed as the strongest permanent magnets to be used in holding. As the magnetic separation and filtration manufacturers are also seeking larger magnetic flux density, mass production of N54 magnets is now possible at some large-scale manufacturers of NdFeB. At the moment, numerous NdFeB manufacturers are able to make the magnets in large quantities. Some even call them N55 magnets since there is no international standard as yet. The name N55 magnet is also used by some manufacturers and customers because of the absence of current international standards.

Osencmag collaborates directly with the high-capacity NdFeB manufacturers who can manufacture technologically advanced N54 magnets with very tight performance tolerances. They have their partner factories with automated sintering lines, high-vacuum furnaces, and laser measurement laboratories to make sure that every N54 batch has a consistent value of Br (remanence), Hcj (intrinsic coercivity) and BHmax. This renders the N54 magnets in Osencmag to fit the high-end industries that need the highest magnetic flux density, like the precision filtration equipment, state-of-the-art magnetic separation systems, medical devices, renewable energy systems, and custom-designed motor structures where each fraction of magnetic performance counts.

The N54 grade of magnet is a super-strong sintered NdFeB permanent magnet, and it is even more magnetic than the N52. The following is a breakdown of everything about the N54 magnet, including its specifications, applications, and demagnetisation curve.

We have tabulated the magnetic performance records of N54 magnets, and we hope everyone will now have a better idea of them.

| Grade | Br | HcJ | HeB | (BH) ax | Working Temperature | Curie Tempera ture | ||||||

| N54 | KGs | T | kOe | kA/m | kOe | kA/m | HGOe | kJ /m3 | C | C | ||

| Min | Min | Min | Min | Min | Min | Min | Max | Min | Max | Max | Max | |

| 14.5 | 1.45 | 11 | 875 | 10.5 | 836 | 51 | 55 | 406 | 438 | 80 | 310 | |

What is the N55 Magnet?

One of the strongest magnets in the market today is the N55 magnet, which can be used commercially. The strength of neodymium rare-earth magnets is measured as 24MGOe down to 55MGOe. This new type of neodymium magnets is 5-6 percent stronger than the more popular N52 grade. The N55 grade of NdFeB is the best feature of permanent magnet technology with unmatched magnetic strength. The N55 grade does not fit in all applications, but in certain situations, it provides clear benefits.

These magnets are also especially applicable in functions where the highest possible magnetic force within a limited area of space is needed. The N55 grade is the most suitable grade of magnet to use due to its strong magnetic field and very fine and delicate application, where size does count. It is quite a powerful magnet. As an example, the Magma engineering team applied them in a recently designed magnetic bearing prototype with these high-power magnets, and proved that the bearings would be as efficient and powerful as possible with the help of the finite element analysis.

Osencmag is partnering with the best rare-earth material factories that are able to make advanced N55 magnets, which are one of the strongest grades of magnets yet to be attained through commercial NdFeB technology. These factories adhere to rigid powder metallurgy, which includes high-purity alloy melting, controlled grain orientation, precision sintering and multi-step surface finishing. Osencmag has made sure that every batch of N55 magnets is of the highest quality in terms of flux density and magnetic energy, and that its customers have a range of ultra-powerful magnets at their fingertips, which can be used in any laboratory instrumentation or micromechanical device that needs peak field strength in the smallest volume.

Osencmag is involved in checking each lot of N55 magnets using standard magnetic field tests, coating checks and heat tests. They also provide engineering assistance to allow customers to safely use N55 magnets in complicated machines. You want a prototype of a motor, a strong magnetic coupling or a test energy device. Osencmag proposes extensive data, samples, experiments, and assistance in creating numerous magnets. This has seen them become a reliable source of companies requiring extremely powerful NdFeB magnets.

Comparison between N52, N54 and N55 Neodymium Magnets.

It is exciting that neodymium magnets are very small and yet extremely powerful, and transform most industries. The strongest types are N52, N54 and N55, and each of them differs in some manner. What makes them different? Which is the strongest? Let us see together.

Osencmag markets the principal high-strength magnets, N52, N54 and N55. Engineers are able to compare actual performance to the consistent samples. Their standard and custom shapes are numerous, therefore customers can experiment with different sizes in terms of pull force, torque, magnetic strength and efficiency. Their technical personnel provide them with data sheets, modeling assistance and demagnetisation charts of each grade, so the engineers can observe actual distinctions rather than mere theories.

The Osencmag collaborates with many specialised factories across the globe, hence all three types of magnets are in stock all the time. Their multi-factory approach provides correct paperwork, consistent quality and custom flexibility like tolerance in size, type of coating, temperature settings, and built-in structures. They assist companies in choosing the most appropriate grade of motors, robots, automation and sensors, as well as strong magnetic components.

| Grade | Br (KGs) | Br (T) | (BH)max (MGOe) | (BH)max (kJ/m³) | Temp. Limit | Cost | Hcb(kOe) | Hcb(KA/m) | Hcj (KOe) | Hcj (KA/m) | Applications |

| N52 | 14.2-14.6 | 1.42-1.46 | 50-53 | 398-422 | 80°C | Moderate | ≥10.5 | ≥955 | ≥12 | ≥955 | Electronics, EVs, Industry |

| N54 | 14.5-15 | 1.45-1.5 | 52-55 | 414-438 | 80°C | High | ≥10.5 | ≥836 | ≥11 | ≥915 | Compact designs |

| N55 | 15.2-15.5 | 1.52-1.55 | 53-56 | 422-446 | 60°C | Very High | ≥10.5 | ≥836 | ≥11 | ≥876 | Aerospace military |

Magnetic Strength

N52 – The most common standard, with 14.3 -14.7 kGs of mag strength and 52 MGOe of energy. It strikes a balance between power, cost and availability.

N54 -A bit stronger, 14.5-15.0 kGs of magnetic strength and approximately 54 MGOe. It is more powerful than N52 but is less widespread as it is difficult and costly to produce.

N55- The most powerful, providing 55 MGOe of energy. It manufactures the largest commercial neodymium magnets.

It is not all about the figures. Rather, it is about the sense of power that is in your hands. Even the minor percentage variations can significantly alter the effectiveness and innovativeness of a real system.

Osencmag is familiar with the measurement and adjustment of magnetic fields. The engineers assist the customers in testing the magnetic strength, the coercive force, energy product, and temperature stability in order to make the magnet suit the project. They also suggest spacing and air gaps, shielding, and putting the magnets together- very crucial towards strong and constant performance.

In the case of high-strength work, Osencmag provides custom test pieces, pairs of magnets and prototype kits to enable engineers to test actual pull force and efficiency. Practical tests allow the customers to obtain trustworthy results of motors, lock systems, lifts, sensors and precision tools. Their testing lowers failure, increases efficiency and extends the life of equipment.

Where Do They Shine? Real-World Applications

N52- N52 is used in consumer electronics, renewable energy, industrial automation, and electric cars. The reason is that it is quite powerful, reliable, and inexpensive.

N54 – Good when a little extra strength is required, but it is more expensive, and so used on special engineering jobs.

N55 – This is used in the aerospace industry, defence and high-tech applications where every mite of strength counts in extremely small dimensions.

Every magnet is a way to bring humanity forward and make the world faster, more productive and more creative.

Osencmag provides neodymium magnets in various applications: renewable energy, automation, electronics, filtration, HVAC, medical equipment, Internet of Things, speakers, magnetic couplings, and brushless motors. They are able to provide either standard or complete custom magnets and allow engineers to produce small but powerful components, which fit in high-stress situations.

Osencmag maintains consistency with large orders, hence their magnets can be used in mass production. They provide material certificates, inspection reports and precise machining, whether you require N52 to be strongly held or N55 to be tallest. Such stability allows industries to produce high-performance products without shortages or bizarre magnet performance.

Which One is the Strongest?

In terms of pure power, N55 is the obvious choice. It possesses the greatest BHmax and Br; therefore, it predominates in magnetic strength. But power alone isn’t enough. N52 remains the most popular in the market with its ability to balance strength, cost and availability. N54 is intermediate – it possesses greater strength than N52 and the same ability to resist loss of magnetism as N52.

There is something special about neodymium. It is the unseen influence of most of the technological improvements. It can drive wind turbines, electric cars can move with greater efficiency, and satellites can be guided through it. Such magnets are silent pioneers of progress. It is what makes them so interesting. It is not just about strength, but it also provides unlimited possibilities.

Osencmag assists the customers to make a decision whether they require the extreme power of N55 or N52, or N54 may be a better mix of engineering and cost. Their suggestions consider torque, sizes, temperature, the distance decay of the magnet, and its long-term durability. This assists every consumer in selecting the grade that is most desirable and not necessarily the best.

| Feature | N55 | N54 | N52 |

| Remanence (Br) | 14.8 – 15.2 kGs | 14.5 – 15.0 kGs | 14.3 – 14.7 kGs |

| BHmax | ~55 MGOe | ~54 MGOe | ~52 MGOe |

| Strength | ~5-6% stronger | ~3% stronger | Strong |

| Temp. Limit | ~60°C | ~80°C | ~80°C |

| Cost | Very High | High | Moderate |

| Applications | Aerospace, Military | Compact designs | Electronics, EVs, Industry |

What Is the Strongest Magnet?

Magnets are strong and shape the modern world in numerous aspects. Their invisible force is important whether it is in small-scale electronics or large-scale industry. It is not an easy task to conclude which magnet is the strongest. The intensity of a magnet, resistance to temperature or the range of the field can be used to measure power. In every measure, there is a different winner.

What is the Magnetic Strength: The Unrivaled Power of Neodymium Magnets

Neodymium magnets are the most appropriate in case we consider magnetic pull alone. They contain neodymium, iron and boron (Nd2Fe14B) and can go up to 55 MGOe. Their high pull has transformed most industries and is applied in high-performance motors, medical imaging, and earbuds. But they may corrupt and lose magnetism when hot.

Heat Resistance: The Strength of Samarium Cobalt Magnets.

Samariumcobalt (SmCo) magnets glow when they become very hot. Their maximum temperature is approximately 350°C, and they work reasonably well without significant degradation, so they are useful where neodymium would fail. They have less pull strength, but their ability to withstand heat is very important in difficult environments.

Field Decay Distance: Reach of Ferrite Magnets.

The distance of the field is also a factor in the magnetic power. Ferrite magnets (prepared using Fe2O3) do not hold fields as strongly as rare-earth magnets, but hold fields at a greater distance. They are employed in big industrial machinery, loudspeakers and household appliances. They are long-lasting and not easily lost in magnetism, hence a permanent choice in a wide range of applications.

Each type of magnet carries its own unique strength, proving that “the strongest” depends on what matters most. Whether it’s the sheer intensity of neodymium, the heat resilience of samarium-cobalt, or the long-reaching influence of ferrite, magnets continue to shape technology, innovation, and the future. Their efficacy is invisible and unbelievable.

Osencmag has a variety of high-performance magnets: NdFeB, SmCo, Ferrite, AlNiCo, and full assemblies. They assist clients in choosing the appropriate material depending on temperature, resistance to corrosion, field strength and mechanical stress. Their experience will provide the most appropriate magnet to the customers in their specific surroundings. They also offer the provision of testing and verification. The customers are able to test the field strength at varied distances, during heat and when the magnet is in motion. This will ensure that the chosen magnet works effectively in the long run. The comprehensive support of Osencmag’s intended material enables their application as a reliable partner when high levels of magnetic reliability are required.

| Magnet Type | Magnetic Strength (BH max) | Max Temp | Field Reach | Key Use |

| Neodymium (NdFeB) | Up to 55 MGOe | 80°C | Short-range | Electronics, motors |

| Samarium-Cobalt (SmCo) | 16-32 MGOe | 350°C | Medium-range | Aerospace, high-temp apps |

| Ferrite | 3.5 MGOe | 180°C | Long-range | Industrial, cost-effective |

Which factors do you consider when selecting the strongest magnet?

When you require a very powerful magnet, you can simply believe that the magnet will have the highest number. But that’s not always true. An N52 high-grade neodymium magnet is able to break at hot locations, and a low-cost ferrite magnet can break under strain. The ideal magnet will depend on its location of use and its functionality.

The most powerful is not necessarily about power. It is concerning the right power to do the job. Think of it like buying a car. A Formula 1 car is highly powerful, and it is not designed to be used in rough off-road environments. This is the same concept of magnets, where one gets the best magnet depending on its application.

The Material Matters More Than You Think.

Neodymium (NdFeB) -Very powerful and susceptible to heat. Works well in small areas where a lot of force is needed, like robotics or delicate sensors. Don’t let it get too hot.

Samarium Cobalt (SmCo) – Strong and heat-tolerant (to 350°C). No rust. Recommended for aerospace or medical devices that require reliability.

Ceramic (Ferrite) -Low cost, hardy and can perform under most conditions. It is not the most powerful, yet it does the job without any additional demonstrations.

Alnico -Old-fashioned, with some applications such as guitars or antique instruments. It will not stand up to the contemporary magnets.

Pro Tip: In the case of neodymium, the suffix (H, SH, UH) should be checked. It reveals the ability of the magnet to cope with the heat. N52 is very powerful, yet N42SH could be more durable in a hot atmosphere. Get the specific neodymium magnet grade regulations to make the most appropriate selection.

Heat Is the Silent Killer

Magnets are efficient at room temperature. Force them out of it, and they become weak or break.

Standard neodymium (N grades) begins to melt at 80°C. It can be used indoors, but not in a hot car.

Neodymium of high temperature (EH, UH grades) can work at temperatures as high as 220 o C – available in motors or heavy gear.

Samarium cobalt is heat-resistant. It is the most appropriate when using a hot engine space magnet.

Fun Fact- When a magnet becomes too hot, it may lose its strength permanently. It will not help to cool it down.

Bigger Isn’t Always Better

A higher weight magnet may seem to pull more; however, shape and position also count.

Narrow, broad magnets distribute the force, and they are excellent at holding flat surfaces.

Tall and narrow magnets concentrate strength in a single direction- excellent for accurate uses.

Even the slight air spacing between the magnet and the target may halve the power.

Quick Hack: One can have the same holding strength with two thinner magnets stacked as with one thick one.

The Undercover Villains: Corrosion and Demagnetization

Neodymium can rust. In case it will be outdoors or wet, a coating like nickel plating can be added.

Over time, the magnets may become weak due to vibration and shock. In the case of moving parts, a higher grade of coercivity should be selected.

Your magnet can be affected by other magnets or electric fields. Always use strong opposing fields unless you desire some unpleasant surprises of demagnetisation.

Best Buy vs. Cost: Don’t Overpay

Neodymium is powerful and costly. Ferrite might suffice in the mass production of cheap fridge magnets.

Samarium cobalt is more expensive. It can only be used when you require a lot of heat resistance.

Custom shapes cost extra. Standard sizes are cheaper.

In Osencmag, we take the best of the magnets, which we try. To make prototypes quickly, we maintain a huge demo inventory of neodymium, samarium cobalt, and other special magnets. Our engineers can save their clients months of theory by testing real-life samples which we already possess.

The strongest that we have are now N52, N54 and N55 magnets. They are matched with power and demand in numerous industries and technologies. These N52 magnets are very powerful and can be used in motors and medical devices.

Osencmag is familiar with the industry. We are fond of producing good magnets of quality, as our experience demonstrates. We do not pass by anything lightly, and all the challenges are taken into consideration.

FAQs

At which point would a magnet be most powerful?

The poles or the ends where the magnetic lines are concentrated the most are the strongest points of the magnetic field. The strongest objects that the magnet can pull or hold are there.

Why cost does the selection of N52 magnets matter?

The N52 grade magnets are the best quality neodymium magnets, and also extremely powerful; hence are more expensive compared to other low-grade magnets. Cost thinking will enable you to select a magnet that is effective and affordable.

Are N52 magnets dangerous?

Yes. N52 magnets are highly powerful and may harm individuals when not handled appropriately, such as pinching fingers or squashing the skin. They can also destroy electronic equipment, magnetic storage or credit cards. Approach them with care and carefulness.

What is the maximum weight that the N52 magnet can hold?

The weight that an N52 magnet can carry is dependent on the size, shape and the surface that the magnet is touching. A few kilograms can be contained in small N52 magnets. For ideal conditions, bigger industrial magnets, with N52, may contain tens or even hundreds of kilograms.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.