A permanent magnet is a material that makes its own magnetic field. This happens because the electrons inside it line up in a special way. I use permanent magnets every day in many ways. In some metals, like iron, cobalt, and nickel, the electrons spin and move in a way that lines up. This makes a strong and lasting magnetic field. I see different kinds of magnets, such as:

- Alloy permanent magnets (like neodymium–iron–boron, samarium–cobalt, and AlNiCo)

- Ferrite permanent magnets

These magnets help power things in homes, cars, and factories. 🧲

Permanent magnet basics

What makes a magnet permanent

A permanent magnet stays magnetized because its atomic structure locks in a strong magnetic field. 🧲

Permanent magnets work because of how their atoms and electrons act. The electrons in these materials have unpaired spins. These spins all point in the same direction. This makes a strong and steady magnetic field. The spins group together into domains. When most domains point the same way, the magnet stays strong for a long time.

Key properties that make a magnet permanent:

- Retentivity: This means the magnet keeps its magnetization even after the outside magnetic field is gone.

- Coercivity: This shows how well the magnet can resist losing its magnetism. If coercivity is high, the magnet stays strong for years.

- Magnetocrystalline anisotropy: This helps the magnet stay stable and not change direction easily.

- Thermal stability: Good permanent magnets lose less than 5% of their strength over many years, even if the temperature changes.

I made a table to show these important properties:

| Property | Description |

|---|---|

| Magnetic Induction (B) | Tells how much magnetic field goes through the magnet. |

| Magnetic Field (H) | Shows how strong the field is around the magnet. |

| Magnetization Vector (M) | Tells the direction and strength of the magnet’s inside magnetization. |

| Coercivity | Shows how much the magnet can resist losing its magnetism. |

| Magnetocrystalline Anisotropy | Helps the magnet stay stable by locking the magnetization direction. |

| Thermal Stability | Tells how well the magnet keeps its power over time and when the temperature changes. |

In summary, a permanent magnet material must have high retentivity and coercivity. I see these features in neodymium, samarium cobalt, and ferrite magnets. These magnets keep their magnetic power because their atomic domains stay lined up. They do not need any outside force to stay strong. This makes permanent magnets useful for motors, electronics, and medical devices. About 30% of all magnets used in industry today are permanent magnets. This shows how important they are in modern technology. ⚡

How permanent magnets work

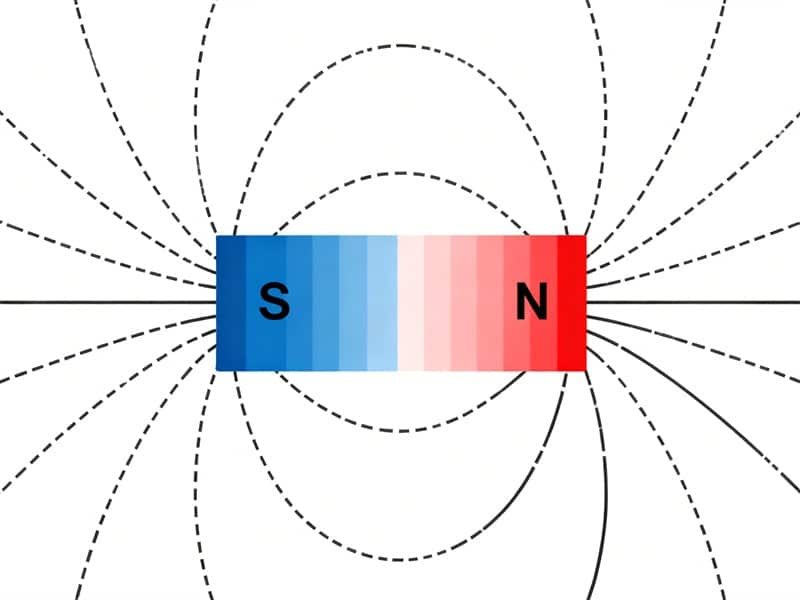

Permanent magnets create a magnetic field because of the way their electrons move and line up inside the material. 🧲

Electrons are tiny parts inside atoms. They spin and move around the center of each atom. In most things, electrons pair up. Their spins cancel each other out. In iron, cobalt, and nickel, some electrons do not pair up. Their spins all point the same way. This makes a strong effect.

Key steps in how permanent magnets work:

- Unpaired electrons in atoms spin in the same direction.

- These spins create tiny magnetic fields called orbital magnetic moments.

- The moments line up together in groups called magnetic domains.

- When most domains point the same way, the whole magnet produces a strong, lasting magnetic field.

This lining up does not happen by chance. The material must be ferromagnetic. Only then can the domains stay lined up. They stay lined up even after any outside force is gone. This is why permanent magnets stay strong for many years.

Here is a simple table to show what happens inside permanent magnets:

| Step | What Happens Inside the Magnet |

|---|---|

| Electron Spin | Unpaired electrons spin in the same direction |

| Domain Formation | Groups of atoms (domains) line up their magnetic moments |

| Domain Alignment | Most domains point the same way, making the magnet strong |

| Lasting Field | The magnet keeps its field without any outside help |

I use permanent magnets in many devices. They do not lose their power easily. About 30% of all magnets in industry are permanent magnets. This shows how important they are for motors, sensors, and electronics. I rely on their steady magnetic field every day.

Magnet Materials

Advanced Materials in Permanent Magnets

The most advanced materials for permanent magnets are rare earth alloys like neodymium-iron-boron (NdFeB) and samarium cobalt. 🧲

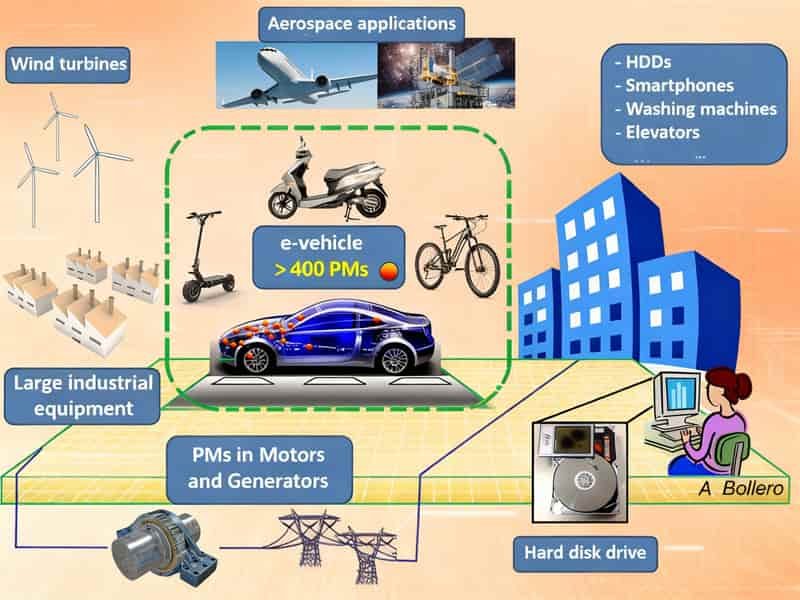

Rare earth permanent magnet materials have changed technology a lot. Neodymium magnets are special because they have the strongest magnetic strength. These magnets are used in electric car motors, wind turbines, and speakers. Samarium-cobalt magnets work well at high temperatures, like in planes and military machines.

Here is a table that shows the most common materials and how much of each is used:

| Material | Composition (by volume) | Composition (by mass) |

|---|---|---|

| Neodymium | 12% | 26.7% |

| Iron | N/A | N/A |

| Boron | N/A | N/A |

| Samarium | N/A | N/A |

| Cobalt | N/A | N/A |

Neodymium and iron are easier to find than samarium and cobalt. This makes neodymium magnets cheaper and more common.

Material Properties and Technological Impact

The unique properties of permanent magnetic materials drive innovation in many industries. ⚡

Rare earth elements like neodymium and samarium cobalt make very strong permanent magnets. Neodymium-iron-boron magnets have the highest magnetic strength. This is important for electric cars and wind turbines. Samarium cobalt magnets stay strong even when it is very hot, so they are used in planes and military tools.

Key impacts of advanced permanent magnetic materials:

- Devices can be made smaller

- Motors work better

- Medical imaging works better

- Magnets stay strong in tough places

The atomic structure of rare earth elements gives these magnets strong magnetic moments and high coercivity. This means they remain stable and perform well even under harsh conditions. These materials help make devices smaller and more efficient. About 30% of all magnets used in industry are advanced permanent magnet materials. This shows how important they are in today’s technology.

Types of permanent magnets

There are five main types of permanent magnets. Each type uses different materials and has its own uses. 🧲

Here is a quick overview of the material composition for each type:

| Type of Magnet | Material Composition |

|---|---|

| Neodymium Magnets (NdFeB) | Neodymium, Iron, Boron |

| Samarium Cobalt Magnets (SmCo) | Samarium, Cobalt |

| Alnico Magnets | Aluminum, Nickel, Cobalt, Iron (plus copper, titanium) |

| Ferrite Magnets (Ceramic) | Iron oxide with barium or strontium |

| Flexible Rubber Magnets | Ferrite powder mixed with rubber or plastic binders |

Neodymium magnets

Neodymium magnets are the strongest and most used permanent magnets. 💪

People use neodymium magnets because they are very powerful. They make magnetic fields much stronger than ferrite magnets. Their energy product is over 50 MGOe. This makes them important for new technology. You can find them in electric car motors and wind turbines. They are also in electronics, speakers, headphones, and medical machines. Even magnetic trains use them.

Key properties of neodymium magnets:

- Very strong magnetic power

- Small size but powerful

- Some types work up to 230°C

Common uses:

- Electric and hybrid car motors

- Wind turbines

- Hard drives, phones, headphones

- MRI machines and other medical devices

- Magnetic gears, brakes, and sensors

At Osenc, I only work with neodymium magnets and their parts. I have many shapes and sizes, from tiny to very big. I also add special coatings for tough or medical places. This keeps them working well.

Samarium cobalt magnets

Samarium cobalt magnets work well in high heat and resist rust. 🔥

I pick samarium cobalt magnets for very hot or tough places. They keep their strength up to 260°C (500°F). They do not lose much power when it gets hot or cold. I use them in planes, military tools, and hot factories.

Advantages of samarium cobalt magnets:

- Resist rust very well

- Stay strong at high temperatures

- Tough and last long in hard places

Common uses:

- Airplane and defense tools

- Strong motors and generators

- Sensors and measuring tools

- Medical and science equipment

Samarium cobalt magnets cost more than others. But they are worth it for important jobs.

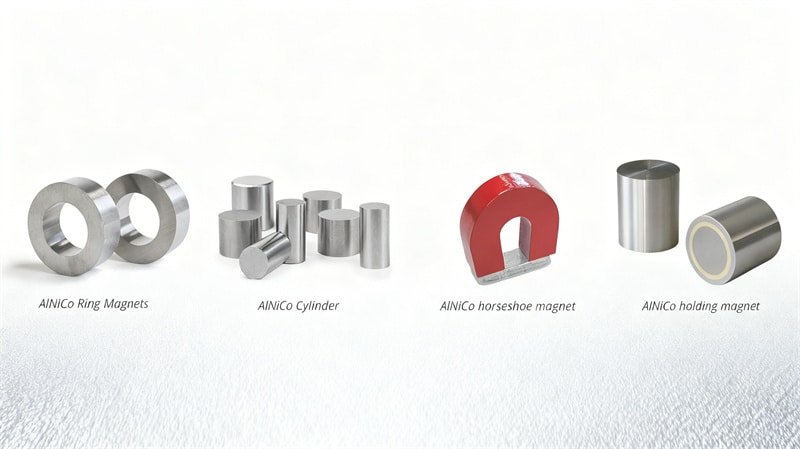

Alnico magnets

Alnico magnets make strong fields and handle heat well. 🎸

I use alnico magnets when I need them to work in heat or under stress. They have aluminum, nickel, cobalt, iron, and a little copper and titanium. They do not rust easily and keep their power in rough places.

Key properties of alnico magnets:

- Work well in high heat

- Strong and tough

- Reliable in hard conditions

Common uses:

- Guitar pick-ups and microphones

- Plane sensors and navigation tools

- Motors and generators

- Medical and science devices

Alnico magnets are still used in music, planes, and factories because they are strong and steady.

Ferrite magnets

Ferrite magnets are cheap, do not rust, and are used every day. 🏠

I pick ferrite magnets for things that do not need a lot of power. They are made from iron oxide and barium or strontium. They work up to 250°C and do not rust, even in water. They are cheap, so they are used in many products.

Key properties of ferrite magnets:

- Do not rust easily

- Hard and keep their power

- Work up to 250°C

Common uses:

- Fridge magnets and whiteboards

- Speakers and small motors

- Car sensors and ABS brakes

- Magnetic separators and machines

Ferrite magnets are used a lot in homes and cars because they are low-cost.

Flexible rubber magnets

Flexible rubber magnets are bendy and easy to shape. 🧲✂️

I use flexible rubber magnets when I need them to bend or fit odd shapes. They are made by mixing ferrite powder with rubber or plastic. They are light, strong, and not expensive. I see them in crafts, toys, signs, and ads.

Key features of flexible rubber magnets:

- Medium strength for close use

- Can bend and take hits

- Easy to cut or shape

Typical applications:

- Fridge seals and iceboxes

- Signs, labels, and displays

- Toys, games, and crafts

- Small motors and electronics

Flexible rubber magnets are great for creative and factory uses where hard magnets will not work.

In summary:

I see many types of permanent magnets in life and work. Each type is best for certain jobs. Neodymium magnets are the most powerful. Samarium cobalt magnets are best for hot or tough places. Alnico magnets work well in heat and stress. Ferrite magnets are cheap and used every day. Flexible rubber magnets are good for bending and shaping.

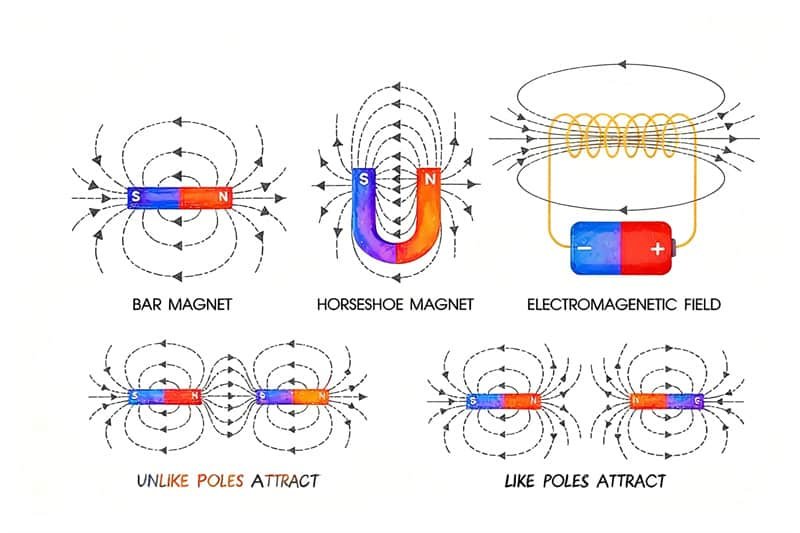

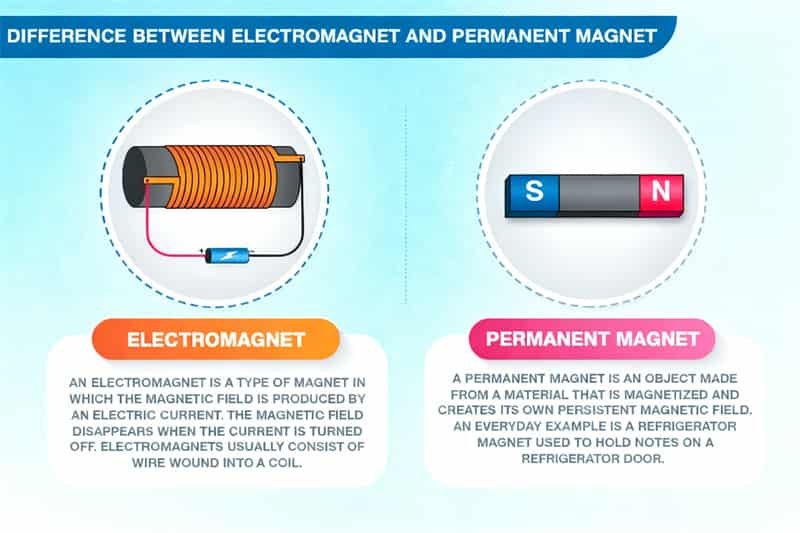

Difference Between Electromagnets & Permanent Magnets

Electromagnets and permanent magnets are not the same. 🧲 They work in different ways and have their own uses. Electromagnets need electricity to make a magnetic field. Permanent magnets have a magnetic field all the time. I use both types for different jobs.

Electromagnets need electric current. Permanent magnets do not need power.

Here is a table that shows the main differences:

| Feature | Electromagnets | Permanent Magnets |

|---|---|---|

| Magnetic Field Generation | Electric current creates the field | Magnetic field exists naturally |

| Power Requirement | Needs power to work | Works without power |

| Magnetic Field Control | Can turn on and off | Always active |

| Strength | Can change with current | Fixed strength |

| Cost and Availability | More expensive and complex | Easier to find and cheaper |

| Applications | Used in electronics, manufacturing | Used in motors, generators, loudspeakers |

Electromagnets can be stronger than permanent magnets if I use enough current. I can change how strong they are. I can also turn them on or off. This is good for machines that need switching. I use electromagnets in cranes, MRI machines, and relays.

Permanent magnets always have a magnetic field. I use them in motors, generators, and speakers. They do not need power, so they save energy. About 30% of all magnets in industry are permanent magnets. I count on them for steady work.

Key points to remember:

- Electromagnets need electricity; permanent magnets do not.

- I can switch electromagnets on and off.

- Permanent magnets work all the time.

- Electromagnets fit jobs that need control.

- Permanent magnets fit jobs that need steady power.

I pick the right type for each job. If I need to control the magnet, I use electromagnets. If I need a magnet that is always strong, I use permanent magnets. Both types help me make better machines and devices. ⚡

Applications of permanent magnets

Household and everyday uses

Permanent magnets power many household items I use every day. 🏠

These magnets are in things like kitchen tools, electronics, and toys. They help doors stay shut, save information, and make sounds. The market for these magnets in homes was $22.18 billion in 2023. It may grow to $39.71 billion by 2030. This shows they are very important in daily life.

Here is a table showing common household items and how magnets work inside them:

| Household Item | Function |

|---|---|

| Refrigerators | A small magnet in the door keeps it closed tightly. |

| Hard Disk Drives | Three magnets help read/write data and spin the disk. |

| Doorbells | Magnets interact with solenoids to make sound when pressed. |

| Microwave Ovens | Magnets in the magnetron create waves to heat food. |

Magnets are also in speakers, headphones, and some toys. These uses of permanent magnets make my life easier and more dependable.

Industrial and automotive applications

Permanent magnets drive innovation in factories and vehicles. 🚗🏭

I use these magnets in motors, sensors, and machines that work by themselves. They help machines work well and safely. In factories, magnets sort materials, lift heavy things, and power robots. In cars, they make driving safer and help cars use less energy.

- I see permanent magnets in:

- Motors for robots and machines

- Magnetic separators for sorting materials

- Lifting tools for heavy objects

- In cars, I use magnets for:

- Anti-lock brakes (ABS)

- Electric car motors (neodymium magnets for better power)

- Fuel pumps, airbag parts, and steering sensors

These uses of permanent magnets help factories and cars save energy and work better. I often pick special coatings for magnets in tough places, like hot or wet spots. Osenc makes strong coatings and custom parts, so magnets last longer and work well in hard jobs.

Electronics and medical devices

Permanent magnets play a key role in modern electronics and medical technology. 💻🩺

I use magnets in computers, phones, and medical machines. They help store data, make sound, and power sensors. In medical tools, they help doctors find and treat problems safely.

- In electronics, I find magnets in:

- Hard drives and speakers

- Microphones and sensors

- Smartphones and tablets

- In medical devices, I rely on:

- MRI machines (strong magnets for pictures inside the body)

- Magnetic drug targeting for careful treatment

- Cochlear implants and dental tools

- Magnetic tools for surgery

- Magnet-based health monitors you can wear

MRI machines use permanent magnets to make strong, even fields for pictures. Neodymium magnets have the highest energy product, so they are great for advanced medical tools. I often choose special coatings for magnets in medical devices to keep them safe and stop rust. Osenc gives these advanced choices for medical and electronic uses.

Advanced engineering and research

Permanent magnets enable breakthroughs in engineering and scientific research. 🧑🔬⚙️

I use magnets in new projects, from new materials to high-tech machines. Research teams make new permanent magnets with advanced methods. They want to use less rare earth elements. For example, the VCU Permanent Magnet Research project looks at other metals like iron, cobalt, nickel, and manganese.

| Project | Description |

|---|---|

| VCU Permanent Magnet Research | Developing new magnets with additive manufacturing to reduce rare earth use. |

I also use magnets in particle accelerators, maglev trains, and special sensors. These projects need magnets in special shapes, sizes, and coatings. Osenc helps engineers design, test, and make custom magnets for research and new technology.

Tip: I always think about temperature, size, and tough conditions when picking magnets for special uses. Advanced coatings and custom solutions from Osenc help me meet strict needs in cars, medical tools, electronics, and research projects.

A permanent magnet makes its own magnetic field and keeps it for years. There are five main types. These are neodymium, samarium cobalt, alnico, ferrite, and flexible rubber. These magnets help in daily life and in factories.

- Permanent magnets are in home appliances and electronics.

- In hospitals, they are in MRI machines and hearing aids.

- In cars and planes, they power motors and sensors.

- In green energy, they help wind turbines and solar panels.

Neodymium magnets made devices smaller and stronger. I use rare earth permanent magnetic products for better electric cars, speakers, and wind turbines. Permanent magnets are everywhere. They help shape the world and industry today.

A permanent magnet is a material that keeps its magnetic field without needing power.

FAQ

What is the strongest type of permanent magnet?

Neodymium magnets are the strongest permanent magnets. 💪

I use these magnets in motors, electronics, and medical devices. Their energy product can go over 50 MGOe. This makes them about 30% stronger than other types.

How long does a permanent magnet last?

A permanent magnet can last for decades. ⏳

Most magnets lose less than 5% of their strength over many years. If used the right way, they keep their power for more than 30 years.

Where do I use permanent magnets most often?

I use permanent magnets in motors, sensors, and electronics.

Here is a quick list:

- Electric car motors 🚗

- Speakers and headphones 🎧

- MRI machines 🩺

- Household appliances 🏠

Can permanent magnets lose their magnetism?

Yes, permanent magnets can lose magnetism.

Some things can make magnets weaker:

- High temperatures above their safe limit

- Strong magnetic fields that go the other way

- Physical damage

In normal use, they lose less than 5% of their power.

What coatings protect permanent magnets?

I use nickel, zinc, epoxy, PTFE, and gold coatings.

| Coating | Use Case |

|---|---|

| Nickel | General protection |

| PTFE | Corrosive environments |

| Gold | Medical devices |

| Epoxy | Electronics |

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.