What is salt spray testing?

Salt spray testing is a laboratory simulation of a corrosive saline environment, also known as salt fog testing. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion.

Some applications, e.g. in sea transport or generally in contact with sea water, require the corrosion resistance to salt water. The tests, which belong to the most widespread tests in this sphere, are neutral salt spray (NSS) tests based on standards: EN ISO 9227 or ASTM B117. A part to be tested is subject to salt spray influence for a time period determined by a customer in a chamber made for this purpose with the possibility of continuously verifying the part condition. The test can be performed on magnets as well as products not only with magnets (metal foils, parts, paints).

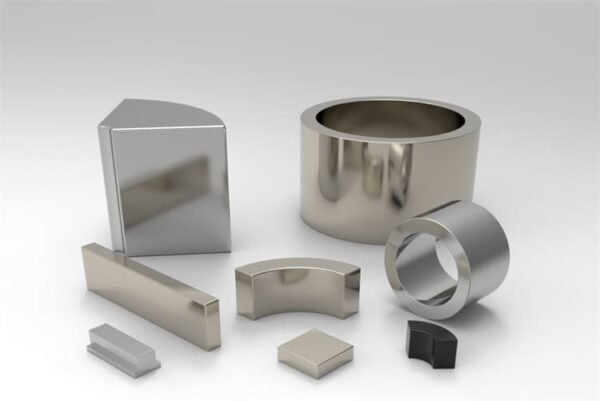

Surface protection of magnets

If there is a risk of using neodymium magnets in an environment with the presence of salt water, the magnets should be provided with additional surface protection, in order to make sure magnets will not rust. The neutral salt spray test of the permanent magnets according to EN ISO 9227 is primarily determined for testing the resistance of their surface protections. Our laboratory tested a greater part of commercially available protections of the permanent magnets and can recommend the most suitable one for a given application.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.