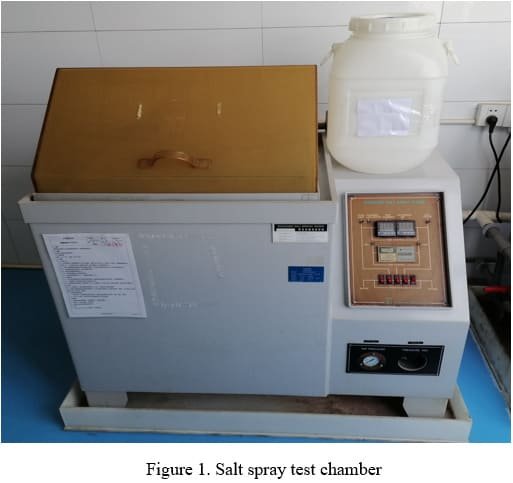

Salt spray test, or salt fog test, is a laboratory technique that is applied to test the corrosion resistance of metals, coatings, and surface finishes. The test is conducted in a special chamber, in which a constant spray of sodium chloride solution around the sample is carried out. This simulated environment accelerates the corrosion process, and the manufacturers can observe results within days that would be observed in months or years in natural conditions.

The chamber is normally heated to 35°C (95°F) and is filled with a 5 percent solution of sodium chloride and a stable pH. Samples are held for hours depending on the performance that is expected of the product. Engineers, after the test, examine the surface of the test in search of rust, pitting, blistering, peeling, or discoloration.

The use of salt spray tests is not intended to simulate all the real-life situations, but rather gives a standardized measure of comparison between the coating and materials. This is the reason why it has been adopted as one of the most common methods of evaluating corrosion in industries.

Why is salt spray testing used for?

Salt spray is performed in various industries where the rate of corrosion has a direct impact on safety, performance, and product life.

Automobile sector

In the automobile sector, the body of the car, the fasteners, exhausts, and chassis parts are tested to guarantee that they can withstand the road salt and de-icing salts. In the case of aerospace, landing gear, fasteners, and structural part finishes must be able to withstand exposure to the humidity level and salinity in the air during operations.

Marine industries

The test is applied in marine industries to test ship fittings, propellers, offshore equipment, and harbor installations exposed to continuous exposure to seawater. The durability of coated steel, pipe construction, roofing, and other construction elements is tested.

Consumer goods

The test is significant even in the case of consumer goods. The humid and corrosive home conditions expose kitchen appliances, bathroom fittings, decorative hardware, and electronics to corrosion. Salt spray testing will make such items functional and good to look at over the years.

Most importantly, this form of testing allows quality engineers to uncover any possible vulnerability in protective coatings, metal alloys, and surface treatments before going to market. In those fields, the salt spray test is an indispensable factor in material selection and design determination.

Why is salt spray testing important?

Salt spray tests are significant since corrosion has a number of destructive implications on materials.

Corrosion effect

Corrosion compromises the mechanical ability of materials. Rusting and pitting also decrease load-bearing capacity, and this may cause cracks or unexpected failures. Corrosion may lead to leaks in pipe,s and corrosion may lead to the breaking of fasteners when they are under stress in pipelines and fasteners, respectively. This allows corrosion to be a safety concern.

Electrical effect

Corrosion leads to high electrical resistance and conductivity interference. Electrical connections, circuit boards, and terminals may be overheated, short-circuit, or fail completely when corroded. This may lead to malfunctions or even fire in vehicles and electronics. Salt spray testing is used to anticipate such failures prior to products being used by consumers.

Physical effect

Products are also ruined in case of corrosion. Blisters, flaking, discoloration, and surface stains render products old and unreliable. This is especially detrimental in the industry where the product value is based on visual appeal, as is the case with luxury cars, appliances, and consumer electronics.

Salt spray testing is also the solution to all three effects and is thus an essential requirement in safety, performance, and appearance.

How does salt spray testing work?

Salt spray test is done by subjecting materials to an artificial, high-accelerated corrosive atmosphere. This is standardized to result in reliable and repeatable results.

Preparation

The samples are washed and coated in the test chamber at some angle, such that all surfaces are exposed equally.

Solution

A solution of sodium chloride is prepared in five percent with or without the addition of other substances such as acetic acid or copper chloride, which makes more aggressive tests.

Spray

This is sprayed continuously inside the chamber in a tiny fine spray by means of compressed air.

Conditions

Temperature is maintained at 35° C, and pH is maintained depending on the type of test.

Duration

Exposure can last from 24 hours for simple coatings to more than 1,000 hours for high-performance coatings.

Assessment

Samples are checked after testing for rusting, cracks, blistering, peeling, and pitting.

Though this type of method is not a copy of all aspects of the actual world, like UV light or temperature variations, it still gives a comparable method to test the resistance to corrosion in various materials.

Salt spray testing regulations

Salt spray tests have rigid international rules to ensure consistency and reliability of results. These rules define:

Solution Composition

Standard test: 5 % NaCl solution.

Special test adjusted solutions:

- Acetic acid (AASS).

- Copper chloride + acetic acid (CASS).

- Water has to be deionized or purified to prevent contamination.

Chamber Conditions

- Temperature: (Typically maintained at) 35° C (95°F).

- PH range: neutral tests: 6.5 to 7.2; acid tests changed.

- Spray rate: Should produce a fine and continuous spray with no large droplets.

Test Duration

- It is stated in the standards ASTM B117 and ISO 9227.

- It takes up to 24 hours to dry simple coats and over 1,000 hours to dry high-technology materials.

- Time varies according to the coating and the purpose it is meant to be used for.

Evaluation Methods

See how much rusting, blistering, peeling, and pitting there is.

Compare rating charts and photos.

Write standardized test reports.

These standards ensure that a salt spray examination performed in one lab will produce the same results as those of the other labs in the country or other parts of the world. Those would be necessary for those companies that pass on parts worldwide and require appropriate certifications.

Advantages of salt spray testing

Salt spray testing offers several benefits. For example,

Speed

When analyzing natural outdoor corrosion, it takes years, whereas with salt spray, compressed results are achieved within days or weeks.

Cost-efficiency

The cost of the testing is not as high as compared of field studies that are long-term.

Standardization

Since it is grounded in international standards, the results are predictable and dependable across the globe.

Versatility

It is suitable for metals, coatings, paint, plated surfaces, and polymers.

Quality control

It is a common practice in routine checks to ensure that the batches are consistent in coating.

Research and development

It is a tool that is used by engineers in comparing various coatings and treatments in the process of designing a product.

These are the benefits that make the test continue to be popular in industries despite the fact that it is usually coupled with other environmental tests to be more accurate.

Salt spray test standards

These are some standards of salt spray testing

ASTM B117

It is the most used standard. It was first published in 1939. It recommends a 5% salt solution, maintaining the test chamber at 35°C, and maintaining a pH of between 6.5 and 7.2. It is still regarded as the gold standard of corrosion tests in many industries.

ISO 9227

An international standard that is well known is ISO 9227. There are three types of tests: Neutral Salt Spray (NSS), Acetic Acid Salt Spray (AASS), and Copper-Accelerated Acetic Acid Salt Spray (CASS). Apply the one that suits the coating: functional, decorative, and very protective.

JIS Z 2371

It is basically the Japanese Industrial Standard. It is extensively employed in manufacturing, cars, and electronics in Japan. It is comparable to the ISO rules, only that it includes Japanese reporting and inspection rules.

DIN 50021

It is a German standard concerning neutral salt spray tests. It is commonly applied in Europe, particularly in construction, steel, and engineering.

Last word

It is an easy and efficient method of establishing the corrosion resistance of a material. The test does not simulate all the conditions of the real world, but it is quick, repeatable, and inexpensive, and hence is most beneficial in quality assurance.

Cars and airplanes, buildings, and even ordinary products are all made with the help of this test, which ensures longer durability of the materials, their safety, and their looks. The same testing rules must be applied to global trade and international supply chains to earn trust between the manufacturers and the customers.

FAQ

What is the ASTM B117 salt spray test?

The primary regulation of salt spray testing is ASTM B117. It recommends a 5% solution of sodium chloride at 35°C and neutral pH. This was initiated in 1939 and forms the foundation of the current salt spray tests.

How to salt spray threaded bolts?

In the chamber, threaded bolts are fitted in such a way that all the threads come in contact with salt mist. To ensure that no section of the bolt remains exposed to the spray, workers ensure that there are no areas that are obscured. The bolts are also inspected after testing to ensure that there is no rust between the threads, and this is where the bolt breaks.

What is the ISO standard of the salt spray test?

The ISO standard is ISO 9227. It can be divided into three forms, namely, NSS (neutral salt spray), AASS (acetic acid salt spray), and CASS (copper-accelerated acetic acid salt spray). Both types take different coatings and materials.

How much does a salt spray test cost?

Testing costs typically range from $200-$800 per batch, depending on exposure duration, specimen quantity, and required documentation. Often, volume discounts apply for regular testing programs.

How many hours of salt spray test?

Test durations vary based on material specifications and industry requirements—ranging from 24 hours for basic screening to 3,000+ hours for high-performance coatings or critical components.

What is a neutral salt spray test?

The most popular test is the neutral salt spray (NSS). It applies a 5% sodium chloride solution, neutral pH, and a 35°C temperature of the chamber. It is the normal method to determine the degree of resistance to corrosion of a material.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.