Neodymium magnets, also known as NdFeB magnets, are powerful permanent magnets made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnets available and are categorized into different grades based on their magnetic strength, such as N35, N42, N52, N54 and N55.with higher numbers indicating stronger magnetic properties. These grades determine their suitability for various applications. Neodymium magnets have a wide range of applications due to their high magnetic strength.

Applications of Neodymium Magnets

Applications of Neodymium Magnets in Electronics and Electrical Appliances

Hard Disk Drives (HDDs)

Neodymium magnets are integral to the functionality of HDDs. They are used in the read/write heads to store and retrieve data efficiently, ensuring fast access and high storage capacity. The precision and reliability provided by these magnets are crucial for the performance of modern computing systems, enabling the rapid retrieval and storage of vast amounts of data.

Speakers and Microphones

In the audio industry, neodymium magnets are preferred for their ability to produce high-quality sound. They are used in the production of speakers, microphones, and earphones. These magnets help achieve superior audio performance by providing a strong magnetic field that enhances the movement of the speaker diaphragm, resulting in clearer and more precise sound reproduction.

Mobile Phones

Various components of mobile phones, including speakers and vibration units, rely on neodymium magnets for optimal performance. Their compact size and powerful magnetic field make them ideal for the slim and lightweight design of modern smartphones, contributing to better sound quality and more efficient vibration functions.

Neodymium Magnets in Motors and Generators

Electric Motors

Neodymium magnets are crucial in the development of electric motors used in electric vehicles (EVs), drones, and industrial machinery. Their strong magnetic fields improve motor efficiency and performance, leading to greater energy efficiency and reduced operational costs. In EVs, these magnets enable more powerful and efficient motors, contributing to longer driving ranges and better overall performance.

Wind Turbines

In wind turbines, neodymium magnets are used in generators to enhance efficiency, contributing to more sustainable energy production. These magnets help convert wind energy into electrical energy more effectively, making wind power a more viable and cost-effective renewable energy source.

Neodymium Magnets in Medical Applications

MRI machines utilize the strong magnetic fields of neodymium magnets to produce detailed images of the human body’s internal structures. These images are crucial for accurate diagnosis and treatment of various medical conditions. The strength and stability of neodymium magnets ensure high-resolution images, allowing for better detection and analysis of abnormalities within the body.

Neodymium Magnets in Industrial Applications

Magnetic Separators and Lifting Magnets

Neodymium magnets are employed in industrial separators to differentiate ferrous materials from non-ferrous ones in recycling and mining industries. They provide a reliable and efficient method for material separation, improving the quality and purity of recycled materials. Additionally, they are used in lifting devices to handle heavy metal objects, offering a safe and efficient way to move and transport large and heavy items in industrial settings.

MRI or Magnetic Resonance Imaging

We know the importance of MRI scans on several medical conditions. A strong magnet such as the neodymium magnet makes the process possible by affecting the electrons of the atoms present in our body. This helps in clicking clear diagnostic pictures of the desired area.

Surgery

In ordinary non-invasive surgery, magnets are the micro magnet, they are often used to connect two tools during surgery. However, in wartime, because of the many wounded, the wounded body generally received more iron pieces. Doctors will use neodymium iron boron to remove iron pieces from the wounded or to check if there is still iron left in the body without an X-ray.

Generators and Motors

Magnets have an important part to play in these devices as well. The permanent magnets help in converting the electrical energy to mechanical energy which helps in the working process of the device.

Lifting Loads

It isn’t an unusual thing to think of and it is definitely used in industries to lift heavy loads. Being a powerful magnet the neodymium does a great job in the field.

Jewelry

People often want to use clasps that are hassle-free. So, small Neodymium magnets help in attaching chains. They also help one to adorn fake piercings by holding them against the skin through magnetic properties.

Door Catches

No one wants to get hit by an unwanted door. That is the reason for using magnetic door catches which efficiently catch the door and are easy to separate as well.

Toy

Magnet is not a toy, that is dangerous. Pls dont give the baby and children the super magnet. But lots of toys have magnets inside, like magnetic tiles, and children’s timber schedules.

Package

Lots of gift box has magnets inside. They make people can open and close it easily.

Art

Magnetic special effects with iron filings and paint. And then put the big magnet behind the canvas and the paint (mixed with iron) begins to move in very interesting swirling patterns.

So, here are some important uses of the Neodymium magnet. It is being widely used in different fields and more work is being done to test its other capabilities. We may soon hope to see it in a lot more things.

Neodymium Magnets Specification

- Thermal coefficient of remanence (Br): -0.09 – -0.11%/°C

- Curie temperature: 320°C – 380°C

- Coefficient of thermal expansion (vertical): 1.0 – 3.0 x 10-6°C-1

- Coefficient of thermal expansion (parallel): +5.0 – +8.0 x 10-6°C-1

- Resistivity: 120 -160 O·cm

- Density: 7.4 – 7.8 g/cm3

- Specific heat: 0.12 Kcal (Kg, °C)

- Thermal conductivity: 77 Kcal/(m.h°C)

- Rigidity: 0.64 N/m2

- Poisson’s Ratio: 0.24

- Vickers hardness: 550 – 650 Hv

- Young’s modulus: 150 – 170 kN·mm-2

- Bending strength: 0.18 – 0.29 kN·mm-2

- Compressive strength: 0.8 – 1.0 kN·mm-2

- Relative recoil permeability: 1.05

- Electrical resistivity: 1.5 x 10-4 Ω/cm

Sizes of Custom Neodymium Magnets

Custom neodymium magnets have various shapes, including rods, discs, blocks, and many other irregular shapes. However, we have different ways to tell the sizes of different shapes. They can be confusing if you don’t have much experience with magnets.

Osenc is a custom neodymium magnet supplier, and we’ve prepared a list to explain how to understand the sizes of custom neodymium magnets. They can be helpful for your communication with the suppliers.

1. Round & Cylindrical Neodymium Magnets

The way for round and cylindrical neodymium magnets is: D10 x 2 mm

If a round or cylindrical magnet has a dimension of D10 x 2 mm, that means its diameter is 10 mm, and the thickness is 2 mm.

Note:

- Nowadays, most people use D instead of Φ, because D is easy to type using computers and mobile phones

2. Ring / Circular Neodymium Magnets

The way for ring / circular neodymium magnets is similar.

- D (or OD) for the outer diameter

- d (or ID) for the inner diameter

- H for the thickness (height)

If a ring / circular neodymium magnet has a dimension of D10 x d7 x 3 mm, that means:

- Its outer diameter is 10 mm, the inner diameter is 5 mm, and the thickness is 2 mm.

Meanwhile, ring neodymium magnets have 2 types of holes: straight and countersunk holes.

- Straight holes are drilled vertically into the magnets

- Countersunk holes (also called screw holes) include a primary hole and a major hole.

For ring or circular neodymium magnets with a countersunk hole:

- D for the outer diameter

- M for the diameter of the major hole

If a ring magnet has a dimension of D10 x M7 x 2 mm, that means:

- Its outer diameter is 10 mm, the major hole diameter is 5 mm, and the thickness is 2 mm.

- Besides indicating the sizes, it’s always good to include the countersunk angle.

3. Block Neodymium Magnets

The dimension for block neodymium magnets:

- Length x Width x Height

- Usually, the dimension begins with an uppercase letter F

If a block neodymium magnet has a dimension of F8 × 4 × 2 mm, that means:

- Its length is 8 mm, the width is 4 mm, and the height is 2 mm.

Block magnets: Length x Width x Height (For example, 10 x 10 x 10 mm)

Block magnets with a hole: Length x Width x Height x Hole diameter (For example, 10 x 10 x 10 x D5 mm)

Block magnet with a countersunk hole: Length x Width x Height x Major hole diameter (For example, 10 x 10 x 10 x M5 mm)

By default, the last number is the magnetization direction of this magnet.

- Therefore, the magnetization direction is the direction of 2 mm, which is the thickness direction for magnetization.

- Meanwhile, N and S are the two bigger surfaces, namely the 8 × 4mm surface.

One side is the N pole, and the other side is the S pole.

4. Arc Neodymium Magnets

The dimension for arc neodymium magnets will need to include:

- Outer radius (R1)

- Inner radius (R2)

- Radian

- Width

The magnetic surfaces are the inside and outside of the arc by default.

Note:

- The shapes of arc neodymium magnets require more numbers to define clearly.

- The dimension formula mentioned above is simplified for easy understanding.

- It’d be better to use technical sketches to indicate all the size information.

5. Spherical Neodymium Magnets

Comparatively, the dimension for spherical neodymium magnets is the simplest:

- D for the diameter

For example, if a spherical magnet has a dimension of D5 mm, that means its diameter is 5 mm.

How to use Neodymium Magnets Safely

1) Neodymium magnets are fragile and brittle.

Neodymium magnets look like metals, but actually, they are not metals. Usually, they have a layer of zinc coating or nickel coating on their surface, and this makes them identical to metals.

They are indeed fragile and brittle, and they can break or shatter if they are dropped or subjected to too much force.

To use them properly, it is important to handle them with care and to avoid dropping them or subjecting them to impact.

2) Neodymium magnets will demagnetize at high temperatures.

Neodymium magnets will lose their magnetism if you use them in a working environment heated to their Curie temperature, which is around 310-370 °C (590-700 °F) for most neodymium magnets.

Once the magnet has cooled, it may regain some of its magnetism, but it will likely not be as strong as it was before it was heated. If you need to use a neodymium magnet in a high-temperature application, there are a few options you can consider:

- Use a different type of magnet

Some magnets, such as samarium cobalt magnets, are more resistant to demagnetization at high temperatures.

- Use a cooling system

If you are using neodymium magnets in a high-temperature environment, you may be able to use a cooling system, such as a fan or a cooling jacket, to keep the magnet at a lower temperature.

- Reduce the temperature

If possible, try to find a way to lower the temperature in the environment where the magnet will be used. This could involve using insulation or other temperature-control measures.

It’s important to note that even if a magnet does not lose all of its magnetism, it may still become weaker at high temperatures. You should carefully consider the temperature tolerance of the magnet when selecting it for a particular application.

3) Neodymium magnets can corrode.

Neodymium magnets are made of an alloy of neodymium, iron, and boron. Usually, they have a layer of coating made from nickel or other materials to protect them from corrosion.

However, the coating can wear off over time, especially if the magnets are subjected to abrasive forces or harsh environments. When the coating is damaged, the magnets may begin to corrode, which can weaken them and reduce their lifespan.

There are a few things you can do to prevent corrosion and protect your neodymium magnets:

- Store the magnets properly:

Avoid storing the magnets in damp or humid conditions, as moisture can accelerate corrosion. If you need to store the magnets for an extended period of time, you can wrap them in a protective material, such as plastic wrap or a plastic bag, to keep them dry.

- Use a better protective coating:

If the magnets will be used in a harsh environment, you can apply a better protective coating, such as PTFE or Parylene. They are more durable to help prevent corrosion.

- Handle the magnets carefully:

Be careful not to drop or knock the magnets, as this can damage the coating and expose the surface to the elements.

By following these precautions, you can help to ensure that your neodymium magnets remain in good condition and continue to perform effectively.

Neodymium Magnets Production Techniques

Generally speaking, neodymium magnets have 2 types of popular production techniques – sintered neodymium magnets and bonded neodymium magnets. The difference between them is mainly in the forming processes.

Bonded neodymium magnets are made by adding neodymium powder to the binder. The bonding process is essentially the same as injection molding.

Meanwhile, sintering is vacuuming and high-temperature heating. Sintered neodymium magnets use powder metallurgy technology. The molten alloy is made into a powder and pressed in a magnetic field to form a briquette.

The briquettes are sintered in an inert gas or vacuum to achieve densification. To improve the coercivity of the magnets, an aging heat treatment is usually required.

Neodymium Magnet coating

Electroplating coating

Electroplating is a kind of technique that use electricity to make metal ions adhere to the surfaces of neodymium magnets, generating a protective layer of coating. This coating technique began to use on neodymium magnets during the years 1985 – 1995. After years of development and optimization, it has been an optimum choice for neodymium magnets. Now it is time for continuous innovation of this coating technique.

Currently, the major options available in the market include zinc plating, nickel plating, nickel-zinc alloy plating, and other composite coating layers of different alloys.

Chemical plating coating

The chemical plating technique doesn’t use electricity to generate coatings for neodymium magnets. It generates a layer of coating for the magnets by accumulating metal ions in the chemical solution on the surface of the substrate, based on the redox reaction.

This technique has some important features, which include: the autocatalytic phenomenon of the substrate itself, the densities and uniformities of the coating layers, low porosities, and relatively simple application facilities.

Thanks to these features, chemical plating has become the most widely adopted coating technique for neodymium magnets. It has been a fundamental production procedure to provide a protective film for neodymium magnets against corrosion and wear.

Nowadays, the main chemical coatings for neodymium magnets include:

nickel-phosphorus, nickel-copper-phosphorus, nickel-tungsten-phosphorus, nickel-copper-phosphorus, etc.

The plating solution used for chemical plating can be divided into 2 types – acidic and alkaline.

In an acidic environment, it tends to produce high phosphorus non-magnetic coating; in an alkaline environment, it tends to produce low phosphorus magnetic coating and has certain magnetic shielding properties.

However, the acidic plating solution has an obvious hydrogen absorbing effect, which seriously affects the surface quality of the neodymium magnets. Therefore, the alkaline plating solution is mostly used in production.

Organic coating

This technique is one of the most widely used methods for protecting metals. Resin and organic polymer materials are the main organic coatings for sintered neodymium magnets, and epoxy resin is used more often. This is because epoxy resin has excellent water resistance, chemical corrosion resistance, bonding capability, and enough hardness.

Add an additional layer of epoxy resin coating to the neodymium magnets that already have a layer of zinc or nickel coating. The magnets will have enhanced antirust performance, which greatly exceeds that of conventional zinc and nickel plating.

In addition to epoxy resin, other resin materials – polyacrylate, polyamide, polyimide, etc. – also use mixtures of two or more of these resins as coatings. Meanwhile, we can also add rust-proof coatings, such as minium, chromium oxide, etc.

Physical vapor deposition coating

Physical vapor deposition is a new coating technology that is different from electroplating and chemical plating.

The coating applied by this method has better bonding quality with the substrates. Such coating layers have higher densities, better smoothness, and fewer porosities.

Meanwhile, this technique can eliminate the residue of electrolytes in the coating layer during electroplating, avoiding secondary damage to the coating layer caused by the residual liquid. And it can reduce the possibility of brittle cracking of the coating, which is caused by the hydrogen gas generated by the magnetic field reaction during chemical plating.

Common physical vapor deposition methods include vacuum evaporation coating, magnetron sputtering coating, multi-arc ion coating, etc.

Common materials include Al, Ti/Al, Al/Al2O3, TiN, Ti, etc.

The coatings generated with this technique has excellent bonding quality with substrates, excellent anti-corrosion performance, and have no waste liquid and other pollution.

For these reasons, this technique is the development direction for neodymium magnets’ anti-corrosion technologies.

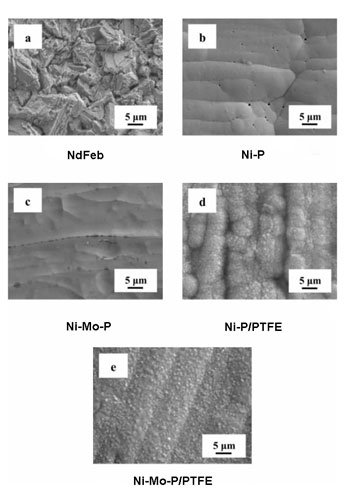

The roughness of Neodymium Magnet Solution

Surface roughness refers to the small spacing and the unevenness of small peaks and valleys on the machined surface. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic geometric shape error. The smaller the surface roughness, the smoother the surface

Increasing the surface roughness of NdFeB can increase the adhesive area and adhesive depth to improve the bonding force between the magnetic steel and the supporting parts, and ensure the reliability and service life of the product.

How to express surface roughness

The mean arithmetical value “Ra” in μm for roughness measurements.

Why pay attention to the roughness?

As the rare earth permanent magnet with the best comprehensive performance, NdFeB has been widely used in consumer electronics, vibration motors in smartphones, speakers, voice coil motors, etc. High-performance NdFeB magnets are used. With electronic technology, and image-sensing technology With the continuous development of technology and computer technology, the optical sensor can recognize the bad surface of the product and the recognition technology of product characteristics is quickly applied to the production line. For the convenience of NdFe The boron products are accurately identified, and the automatic assembly process has no problem with the surface roughness of NdFeB products degrees have specific requirements.

What factors affect the roughness

There are many factors affecting the magnetic roughness, the nature of the processing material itself, the processing method, the abrasive material, the cutting process, etc., the cleaning process and the electroplating process will also affect the roughness of the magnet surface.

How to improve roughness

There 4 main ways to improve roughtess.

Grinding the magnet

For ordinary magnets, it can be polished. Make the surface smoother. But for tiny magnet it cannot be ground because that i too small to process.

Make a coating

Plating helps to improve roughness. Among all coatings, Teflon has the smallest roughness and the best performance. The performance of parylene is also very good, but different parylene has different roughness. As far as commonly used coatings are concerned, the surface roughness of galvanizing is better than that of nickel plating.

New cutting process

Laser cutting is a new technology, but this technology is still unstable.

Acid washing process

This process is suitable for all sizes of NdFeB. According to the conclusion of the study “Effect of Nitric Acid Pickling Process on Surface Roughness Ra of Sintered Nd-Fe-B Products”, the pickling process helps to improve the roughness.

FAQ

Why neodymium magnets need chamfers?

Neodymium magnets are widely used in various fields, thanks to their high magnetic energy, remanent magnetism, and cost-effectiveness.

However, they are fragile and easy to break, so it is easy for them to be bumped during the production or application processes, which leads to broken edges and corners, etc. For this reason, neodymium magnets are usually chamfered.

Which Magnet Is Stronger Than The Neodymium Magnet?

In over 10 years, a lot of experimental work has been done on Iron and Nitrogen in order to combine for manufacturing a much stronger iron nitride magnet. In the beginning, experiments produced only thin films or powders which were not appropriate and suitable for many applications.

But, when the fabrication process was employed and it produced the magnet in the bulk form that can be used in a number of applications. Moreover, the fabrication process is very compatible with the existing mass-production techniques. Nitrogen and iron inputs are comparatively low cost, hence enabling extremely cheap permanent magnets which exceed the performance of the rare earth magnets.

how to demagnetize neodymium magnets

Neodymium magnets will gradually lose their magnetism (demagnetize) when they are heated to exceed its maximum working temperature.

Their magnetism will disappear completely when they are heated to exceed their Curie temperatures, then they will be transformed into paramagnetic materials.

And they will recover to ferromagnetic materials when their temperatures drop below their Curie temperatures.

Temperatures to demagnetize neodymium magnets

Working temperature 80℃ – 240℃ (176°F – 464°F)

Curie temperature 310℃-350℃ (590°F – 662°F)

N: Maximum working temperature 80℃ (176°F), Curie temperature 310℃ (590°F)

M: Maximum working temperature 100℃ (212°F), Curie temperature 340℃ (644°F)

H: Maximum working temperature 120℃ (248°F), Curie temperature 340℃ (644°F)

SH: Maximum working temperature 150℃ (302°F), Curie temperature 340℃ (644°F)

UH: Maximum working temperature 180℃ (356°F), Curie temperature 350℃ (662°F)

EH: Maximum working temperature 200℃ (392°F), Curie temperature 350℃ (662°F)

AH: Maximum working temperature 230℃ (446°F), Curie temperature 350℃ (662°F)

Refer: Neodymium magnet wiki

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.