A holding magnet is a device that creates a strong suction force to attract and secure metal objects right where I need them. I use these magnets whenever I want to keep something in place—whether that means lifting heavy metal sheets in a factory or snapping a cabinet door shut at home. They play a huge role in both industrial and everyday life, showing up in everything from medical devices to automotive sensors. Just check out how many fields rely on them:

| Industry | Common Uses |

|---|---|

| Aerospace | Actuators, safety systems |

| Manufacturing | Material handling, robotic arms |

| Medical Devices | MRI machines, surgical tools |

| Automotive | Motors, sensors, actuators |

| Electronics | Magnetic closures, device mounting |

🧲 Holding magnets really do make work and daily routines easier!

Holding Magnet Overview

What Is a Holding Magnet

A holding magnet is a specialized magnet designed to grip, secure, or position metal objects using concentrated magnetic force. When I use a holding magnet, I notice how its unique shape and construction create a powerful suction that keeps metal parts exactly where I want them. These magnets come in many forms, but the most common type features a U-shaped or horseshoe design. This shape brings the poles close together, which concentrates the magnetic field and boosts the holding power. I rely on holding magnets for tasks like lifting tools, clamping workpieces, or keeping doors shut.

Osenc stands out as a leading supplier of neodymium holding magnets. Their products deliver exceptional strength and reliability, making them my go-to choice for demanding jobs. I trust Osenc because they manufacture magnets under strict ISO9001 and ISO16949 certifications, which means I get consistent quality every time.

💡 Tip: If you need a magnet that holds tight and stays strong, look for one with a concentrated magnetic field and certified manufacturing standards.

Key Differences from Other Magnets

Holding magnets differ from other magnets in both structure and function. I see this every time I compare them to regular bar or disc magnets. While most magnets have a simple shape and spread their magnetic field over a wide area, holding magnets focus their force between closely spaced poles. This design creates a much stronger grip in a small area, which is perfect for lifting, clamping, or securing metal objects.

Let me break down the main types of magnets you’ll find in the market and how they stack up against holding magnets:

| Type of Magnet | Definition | Outstanding Feature | Applications |

|---|---|---|---|

| Ceramic or Ferrite Magnets | Made from iron oxide and strontium carbonate, durable under various conditions. | Highly resistant to demagnetization and corrosion. | Used in electric motors, magnetic separators, and speakers. |

| Alnico Magnets | Composed of aluminum, nickel, cobalt, and iron, stable at high temperatures. | Excellent temperature stability and high magnetic flux. | Ideal for sensors and volt meters operating at high temperatures. |

| Samarium Cobalt (SmCo) Magnets | Made from samarium and cobalt, part of rare earth magnets. | Excellent thermal stability and resistant to demagnetization. | Suitable for aerospace and military applications. |

| Neodymium Iron Boron (NdFeB) Magnets | Composed of neodymium, iron, and boron, known as the most powerful magnets. | Exceptionally high magnetic properties. | Used in hard disk drives, electric motors, MRI machines, and magnetic therapy devices. |

I often choose neodymium holding magnets from Osenc because they offer up to 30% more holding power than standard ceramic magnets. That extra strength makes a big difference when I need to secure heavy or awkward items.

Here’s what sets Osenc apart for me:

- ISO 9001 certification ensures top-notch quality management.

- ISO 16949 certification means their magnets meet strict industry standards.

- Their magnets are precision-made, so I get reliable performance every time.

🛡️ Note: Not all magnets are created equal. If you want maximum holding force and durability, go with certified neodymium holding magnets from a trusted supplier like Osenc.

How They Work

Magnetic Force Explained

A holding magnet works by creating a concentrated magnetic field that grips metal objects securely. When I use one, I see how the magnet pulls metal parts toward itself and holds them in place. The secret lies in the way the magnetic field lines focus between the poles, which boosts the force right where I need it. This makes lifting, holding, or positioning metal sheets much easier and safer.

I often rely on holding magnets for tasks like lifting steel plates or securing tools during assembly. The physical principles behind these magnets help me work faster and with less risk. I always notice that neodymium magnets, like those from Osenc, deliver superior strength and reliability compared to other types. Here’s a table that shows how different magnets stack up:

| Magnet Type | Strength | Reliability |

|---|---|---|

| Neodymium | Superior strength, compact | Better coercivity, less susceptible to external fields |

| Ferrite | Cost-effective, performs better in high temperatures | Lacks the same level of strength as neodymium |

Neodymium magnets can be up to 30% stronger than ferrite magnets. That extra power means I can trust them for heavy-duty jobs.

Factors Affecting Holding Power

Several factors affect how much force a holding magnet can deliver. I always check these details before choosing the right magnet for my project. Let me break down the most important ones.

Surface and Material Impact

The type of metal and the condition of the surface play a huge role. If I use a magnet on clean, flat steel, I get maximum holding power. Rust, paint, or uneven surfaces can reduce the grip by 20-50%. I also look at the material itself. Neodymium magnets are the strongest, while ceramic and Alnico magnets offer more resistance to corrosion and temperature changes.

| Factor | Description |

|---|---|

| Material Type | Neodymium magnets are the strongest; Samarium Cobalt offers high strength with temperature resistance; Alnico and ceramic magnets are weaker but more resistant. |

| Environment | Moisture and oxidation can degrade performance, especially for uncoated neodymium. |

💡 Tip: For best results, I always use Osenc neodymium magnets on clean, flat steel surfaces.

Magnet Size and Shape

Size and shape matter a lot. Larger magnets produce stronger fields, but the shape controls how that field spreads. I find that disc-shaped magnets work well for broad contact, while block magnets focus the force in a smaller area. Geometry can change the holding power by up to 40%. I also keep in mind that the strength drops quickly as the distance from the magnet increases.

| Factor | Description |

|---|---|

| Size and Shape | Larger magnets produce stronger fields; geometry affects field distribution. |

| Distance from Magnet | Magnetic strength drops rapidly with distance, following an inverse cube law. |

I always choose the right size and shape for the job. Osenc offers custom shapes, so I can get exactly what I need for any project.

🧲 Note: Magnet aging and rough handling can weaken magnets over time. I store my magnets carefully to keep them strong.

Holding Magnet Features

Design and Materials

The design and materials of a holding magnet determine its strength, durability, and suitability for different jobs. When I pick a magnet for my project, I always look at what it’s made of and how it’s built. Most high-performance magnets use neodymium iron boron (NdFeB) because it packs a lot of energy into a small space. Ferrite magnets work well for budget-friendly tasks but don’t offer the same power.

Here’s a quick table that shows how material choice impacts performance:

| Material | Key Properties | Impact on Performance |

|---|---|---|

| Neodymium Iron Boron (NdFeB) | High energy product, high coercivity, high remanence | Boosts energy density and efficiency in motors, generators, and precision tools. |

| Ferrite Magnets | Lower energy product compared to NdFeB | Good for cost-effective uses, but with less holding power. |

I often choose Osenc neodymium magnets for tough jobs. Their micro magnets and custom shapes help me tackle unique challenges, whether I need a tiny magnet for electronics or a large one for lifting.

Strength Ratings

Strength ratings tell me how much force a holding magnet can handle before it lets go. I always check these numbers before I trust a magnet to hold something heavy. The most common way to measure strength is the MDFA Pull Test Standard. This test shows the breakaway force—the amount of force needed to pull the magnet off a metal surface.

Here’s how strength ratings are determined:

| Testing Method | Description |

|---|---|

| MDFA Pull Test Standard | Measures the breakaway force to ensure consistent strength ratings. |

| Breakaway Force | The force (in pounds) needed to detach the magnet under controlled conditions. |

- MDFA Pull Test Standard gives me reliable numbers.

- Breakaway force helps me compare magnets for different jobs.

Osenc magnets always meet strict standards, so I know I’m getting accurate strength ratings. Their precision manufacturing means I can trust the numbers—sometimes up to 30% more holding power than other brands.

Safety Considerations

Safety is crucial when I use powerful magnets, especially neodymium types. These magnets can snap together quickly and pinch my skin. They can also mess with electronics and medical devices like pacemakers. I always wear gloves and keep magnets away from sensitive equipment.

Here’s what I do to stay safe:

- I wear gloves to avoid pinching injuries.

- I store magnets in dry, cool places to prevent rust and keep them strong.

- I keep magnets away from phones, laptops, and medical devices.

- I use eye protection because neodymium magnets can break and send sharp pieces flying.

- I never let kids play with strong magnets—they can be a choking hazard.

- Neodymium magnets can disrupt electronics and medical devices.

- They can pinch skin and cause injury.

- Magnet dust is flammable, so I handle it carefully.

- Uncoated magnets rust easily in humid places.

Osenc always provides safety guidelines with their products. Their magnets come with coatings to reduce corrosion and packaging that keeps me safe during shipping.

🧲 Tip: I use non-metallic tools to separate magnets and always follow transportation rules for safe shipping.

Precision Manufacturing and Tolerances

Precision manufacturing makes a huge difference in magnet performance. I look for magnets with tight tolerances because even a small error can lower holding power. For example, Osenc neodymium magnets have tolerances as tight as ±0.02 mm. That means I get consistent results every time.

Here’s a table showing typical tolerances for different magnet types:

| Magnet Type | Tolerance Range |

|---|---|

| Sintered NdFeB | ±0.02 mm to ±0.05 mm |

| Bonded NdFeB | ±0.05 mm to ±0.1 mm |

| Sintered SmCo | ±0.02 mm to ±0.05 mm |

| Bonded SmCo | ±0.1 mm |

| Sintered Ferrite | ±0.1 mm to ±0.2 mm |

| Bonded Ferrite | ±0.1 mm to ±0.2 mm |

| Sintered Alnico | ±0.05 mm to ±0.1 mm |

| Cast Alnico | ±0.1 mm to ±0.2 mm |

I trust Osenc for precision and reliability. Their magnets help me get the job done right, every time.

Applications

Industrial Uses

Holding magnets play a crucial role in industrial settings by providing strong, reliable grip for heavy-duty tasks. I see them everywhere in factories and workshops, making my work safer and more efficient. These magnets help me handle, lift, and position metal parts with precision.

Machining and Assembly

When I work on machining and assembly, I rely on different types of magnets based on the job. Alnico magnets, made from aluminum, nickel, cobalt, and iron, come close to their final size and need little machining. Neodymium Iron Boron magnets offer high energy density and can be shaped for custom features, though I stay cautious about dust. Samarium Cobalt magnets are brittle, so I handle them with care. Ceramic magnets, hard and brittle, require diamond tooling for machining. Each type brings its own benefits and challenges to the table.

Osenc helps me tackle unique machining needs by offering custom assemblies and precision-shaped magnets. Their expertise lets me choose the right magnet for every operation.

Lifting and Positioning

I use holding magnets for lifting and positioning metal sheets, tools, and components. Heavy duty magnets give me the strength I need to move large items safely. Pot magnets, with their steel casing, focus the magnetic field and boost holding power. Ceramic magnets work well for tasks that need corrosion resistance.

Here’s a quick look at common industrial applications and what they demand from magnets:

| Application Area | Performance Requirements |

|---|---|

| Pharmaceuticals | Strength, cleanability, suitability for processes |

| Transportation | Strength, safety, efficiency |

| Industrial Equipment | Strength, reliability, integration with devices |

I trust Osenc for magnets that meet strict performance standards, especially when I need reliability and safety.

Everyday Uses

Holding magnets make life easier at home, in the office, and during DIY projects. I use them for organizing, securing, and even creating fun solutions.

Home and Office

Magnets show up in many household gadgets and office tools. I see them in doorbells, microwaves, and refrigerator doors. Magnetic racks help me organize spices and knives, saving counter space. Cabinet doors stay shut with magnetic latches, and computers use magnets for data storage. Neodymium magnets keep my office supplies like clips and thumbtacks in order. Extendable tables use magnets to hold extra pieces in place. Outdoor parties get easier when I use magnets to secure tablecloths against the wind.

| Use Case | Description |

|---|---|

| Doorbell | Contains magnets and solenoids that create sound when the button is pressed. |

| Microwave | Uses magnetrons with magnets to generate electromagnetic waves for heating food. |

| Refrigerator doors | Sealed with magnetic mechanisms for easy opening. |

| Spice and knife rack | Magnetic racks help organize kitchen utensils and save counter space. |

| Cabinet doors | Secured with magnetic latches to prevent unintentional opening. |

| Computers | Utilize magnets in hard drives for data storage and in CRT screens for display. |

| Organizing office supplies | Neodymium magnets help keep metal office supplies like clips and thumbtacks organized. |

| Extendable tables | Use magnets to hold additional pieces in place. |

| Outdoor parties | Magnets can secure tablecloths against wind without damaging surfaces. |

Osenc offers micro magnets and custom shapes, so I always find the right solution for my home or office needs.

Automotive and DIY

Magnets bring creativity and convenience to automotive and DIY projects. I use countersunk rare earth magnets for releasable fixtures like magnetic picture frames and modular shelving. These magnets hold strong without bulky hardware, making my DIY organization simple. Bar magnets attach to toy cars, letting me control them with a hovering horseshoe magnet—a fun way to explore magnetism.

- I use countersunk rare earth magnets for modular shelving and picture frames.

- These magnets provide strong holding power for DIY solutions.

- Bar magnets make toy cars move with magnetic force, adding a playful touch.

Osenc supports my DIY ambitions by providing custom assemblies for unique projects. Their wide range of magnets lets me experiment and create with confidence. 🛠️

💡 Tip: For any project—industrial or personal—I always choose the right magnet type and size for the job. Custom assemblies from Osenc help me solve even the toughest challenges.

Types of Holding Magnets

Permanent Magnets

Permanent holding magnets create a constant magnetic field and do not need electricity to work. I use these magnets when I want reliable, long-lasting grip for my projects. They keep their magnetism over time, so I never worry about losing strength. I find permanent magnets in motors, generators, and even MRI machines.

Here’s what sets permanent magnets apart from electromagnets:

- Permanent magnets always retain their magnetism.

- Their strength stays fixed, unlike electromagnets that can change with more or less current.

I like to compare permanent magnets and electromagnets side by side:

| Characteristic | Permanent Magnets | Electromagnets |

|---|---|---|

| Magnetism Retention | Retain magnetism without external power | Require electric current to generate magnetic field |

| Composition | Made from ferromagnetic or ferrimagnetic materials | Typically made from coils of wire |

| Magnetic Strength Control | Fixed strength based on material and size | Strength can be adjusted by changing current |

| Reliability | High reliability, consistent performance | Dependent on power supply |

| Applications | Used in motors, generators, MRI machines, etc. | Used in devices requiring variable magnetic fields |

Permanent magnets maintain a consistent magnetic field. They resist environmental changes and stay strong even in tough conditions. Their magnetic properties, like coercivity and remanence, make them dependable for everyday use. I often choose Osenc’s neodymium permanent magnets because they deliver up to 30% more holding power than standard ceramic magnets.

💡 Tip: Permanent magnets work best when you need steady, reliable force without worrying about power outages.

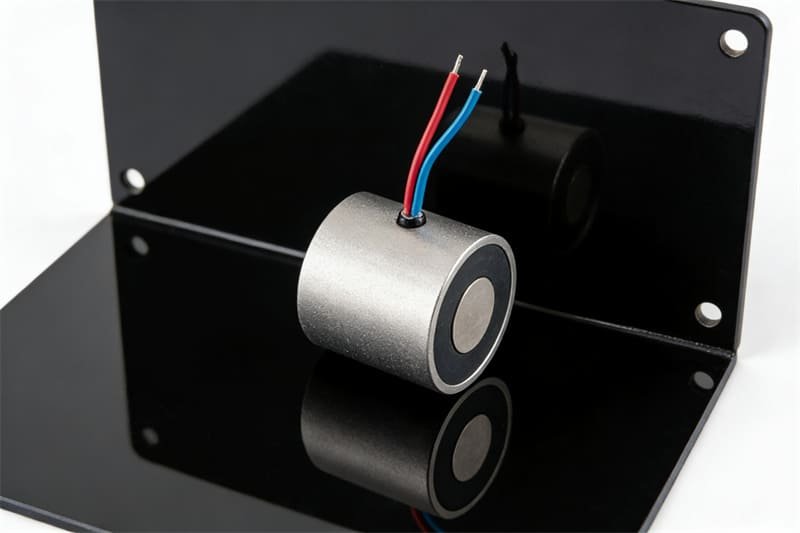

Electromagnets

Electromagnets generate magnetic force only when electricity flows through them. I use these magnets when I need to control the strength or turn the magnet on and off. Electromagnets come in handy for lifting heavy metal sheets in factories or operating machinery that needs variable force.

Electromagnets differ from permanent magnets in several ways:

- They need electric current to work.

- I can adjust their strength by changing the current.

- They stop working if the power goes out.

I like using electromagnets for tasks that require flexibility. For example, in automated assembly lines, I can switch the magnet on to hold a part, then turn it off to release it. This control makes my job easier and safer.

Osenc offers custom electromagnet solutions for industrial clients. Their engineering team helps me design magnetic assemblies that fit my exact needs.

⚡ Note: Electromagnets give you control, but always check your power supply before relying on them for critical tasks.

Ceramic Magnets

Ceramic holding magnets provide a cost-effective solution with good magnetic strength and high resistance to corrosion. I reach for ceramic magnets when I need reliable grip in environments where moisture or chemicals might be a problem. These magnets work well in outdoor settings and places with temperature changes.

Ceramic magnets have their own set of advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Cost-effectiveness | Brittleness |

| Good magnetic strength | Limited magnetic strength |

| High resistance to corrosion | Temperature sensitivity |

| Temperature stability | Corrosion susceptibility |

I like ceramic magnets for their affordability and durability. They resist rust and stay stable in most temperatures. However, they can break if dropped or hit, and their strength doesn’t match neodymium magnets. For heavy-duty jobs, I stick with Osenc’s neodymium options, but ceramic magnets still have a place in my toolbox for lighter tasks.

🧲 Tip: Use ceramic magnets when you need a budget-friendly, corrosion-resistant solution for everyday holding tasks.

Heavy Duty Magnets

Heavy duty magnets deliver maximum holding power for the toughest jobs. I reach for these magnets when I need to secure, lift, or move heavy metal objects in demanding environments. Their strength comes from advanced materials like neodymium, which can provide up to 30% more force than standard magnets. I use heavy duty magnets in places where safety and reliability matter most.

You’ll find these magnets in CNC shops, manufacturing plants, and construction yards. They help me lift steel plates, hold large assemblies, and keep equipment in place. Here’s a table that shows typical load capacities and where I use heavy duty holding magnets:

| Application | Load Capacity |

|---|---|

| CNC and Fabrication Shops | Up to 660 lbs |

| Manufacturing and Assembly | Up to 2200 lbs |

| Machine Shops | Up to 2200 lbs |

| Steel Service Centers and Warehouses | Up to 2200 lbs |

| Construction and Heavy Equipment Yards | Up to 2200 lbs |

I always check the load rating before I trust a magnet with a heavy object. Osenc offers heavy duty neodymium magnets that meet strict industry standards, so I know I’m getting reliable performance every time.

💪 Tip: For lifting and securing large metal parts, I choose heavy duty magnets with certified load capacities.

Heavy duty magnets also come with features like corrosion-resistant coatings and reinforced casings. These details help them last longer, even in harsh conditions. I like using magnets with easy-release handles, which make my work safer and faster.

Pot Magnets

Pot magnets combine strong magnetic pull with extra durability, thanks to their steel shell. I use pot magnets when I need a magnet that can handle rough handling and environmental stress. The steel casing protects the magnet from chips, cracks, and corrosion, so it lasts longer than other types.

Pot magnets focus their magnetic force on one side, which gives me better grip and control. I find them useful for mounting, holding, and positioning tasks in workshops, warehouses, and even at home. Here’s a table that highlights the main features and benefits of pot magnets:

| Feature/Benefit | Description |

|---|---|

| Durability | Steel shell prevents damage from chips, cracks, and corrosion. |

| Enhanced Magnetic Pull | Design channels magnetic flux to the exposed surface for stronger grip. |

| Versatile Mounting Capabilities | Adaptable to many applications and mounting options. |

| Cost-Effectiveness | Reliable solution at a competitive price. |

When I need a magnet that works in tough conditions, I pick pot magnets. Their protective shell keeps dust and moisture out, so the magnetic strength stays high over time. Osenc supplies pot magnets with high holding strength and versatile mounting options, which makes my projects easier.

Here’s why I like pot magnets:

- High holding strength for secure grip

- Durable and protected against damage

- Versatile for many uses

- Good for the environment

- Cost-effective for my budget

🧲 Note: Pot magnets work well in places where regular magnets might break or lose strength. I use them for mounting signs, securing tools, and holding fixtures in place.

Pot magnets give me peace of mind. I know they’ll hold up under pressure and keep my workspace organized. If I need a custom solution, Osenc can create pot magnets that fit my exact requirements.

Choosing Magnets

Selection Factors

I always start by matching the magnet to my project’s needs. The right holding magnet makes all the difference, so I look at several factors before making a choice.

Load and Environment

I check how much weight the magnet needs to hold and where I’ll use it. If I’m working in a hot factory or a damp garage, I pick magnets that can handle those conditions. I also consider what kind of metal the magnet will grip—steel, aluminum, or something else. Here are the main things I look for:

- Operating temperature—Will the magnet face heat or cold?

- Environmental conditions—Is there moisture, chemicals, or dust?

- Dimensional constraints—Does the magnet need to fit in a tight spot?

- Integration—Will it be part of a bigger assembly or work alone?

- Coating requirements—Does it need extra protection from rust or corrosion?

Osenc helps me out with custom coatings and shapes, so I always get a magnet that fits my environment perfectly. 🏭

Size and Shape

I choose the size and shape based on space and field needs. If I need a strong, focused grip, I go for U-shaped or horseshoe magnets. For tight spaces, I pick compact shapes like cylinders or flat discs. When I want uniform strength, ring or disc magnets work best. I also look for shapes that make assembly easy.

- U-shaped or horseshoe magnets focus the field at the poles.

- Cylindrical or flat magnets fit tight spaces.

- Ring or disc shapes give consistent field strength.

- Shapes that are easy to assemble save me time.

Osenc offers free samples and OEM/ODM services, so I can test different shapes before I commit. That flexibility helps me avoid costly mistakes. 🧲

| Evidence Type | Description |

|---|---|

| OEM/ODM Capabilities | Osenc provides tailored solutions, ensuring quality and allowing customers to evaluate products. |

| Free Sample Offerings | Customers can receive free product samples to assess quality before making a commitment. |

| Comprehensive Support | The team offers support from technical assistance to after-sales service, ensuring satisfaction. |

Maintenance Tips

I keep my magnets in top shape with regular care. A little attention goes a long way toward keeping them strong and safe.

- I never submerge magnets in water—rust and weakened magnetism are real risks.

- I check the magnet’s strength often and replace it if it starts to fade.

- I avoid dropping or hitting magnets, since impacts can crack or chip them.

- I watch out for temperature extremes, which can lower holding power by up to 30%.

- If I see surface rust, I use a soft cloth with a bit of anti-rust solution—never too much.

Osenc backs their magnets with a three-year warranty and lifetime technical support. That means I get help whenever I need it, plus free manuals and engineering advice. 🛡️

| Warranty/Support Option | Details |

|---|---|

| Warranty on Repairs | All authorized repairs come with a full 12-month warranty on the work performed. |

| Application Engineering Assistance | Free application engineering assistance is available. |

| Manuals | Manuals are provided at no charge. |

| Major Repair Cost Estimate | An accurate cost estimate will be provided before major repairs or rebuilding. |

💡 Tip: I always ask about warranty and support before buying. Osenc’s technical team helps me solve problems fast, so I can focus on my projects.

Pros and Cons

Advantages

Holding magnets offer powerful benefits for both industrial and everyday use. I see these advantages every time I use them in my projects. They make my work easier and safer, and they help me get more done in less time.

- 🏭 Boosted productivity: I can lift and hold objects quickly, which speeds up my workflow.

- 🦺 Improved safety: Magnets reduce the need for manual lifting, so I avoid injuries.

- 🍽️ Cleaner operations: In food and agriculture, magnets prevent contamination by trapping metal fragments.

- 💰 Lower costs: I waste less material and save money because magnets help me work more efficiently.

When I use holding magnets in my shop, I notice how they keep my workspace organized and reduce clutter. Osenc magnets, with their strong neodymium cores, help me automate tasks without changing my setup. I get better product quality and a safer environment for everyone.

Industrial magnets also enhance product purity and minimize wear on machinery. I see fewer breakdowns and less downtime. Automation becomes easier, and I don’t need to invest in expensive new equipment. These benefits matter in both factories and homes.

💡 Tip: If you want to improve safety and efficiency, holding magnets are a smart choice.

Limitations

Holding magnets have some limits you should know before choosing one for your project. I always check these factors to avoid surprises, especially in tough environments.

| Limitation | Description |

|---|---|

| Mechanical Stress | Magnets can chip or crack if they face vibration, impact, or constant movement. I use proper support to prevent damage. |

| Temperature Extremes | High heat can lower magnet strength by up to 30%. Cold can affect precision sensors. I pick magnets rated for the right temperature. |

| Moisture and Corrosive Elements | Water or chemicals can cause corrosion. I choose magnets with protective coatings or made from resistant materials, like those from Osenc. |

| External Magnetic Fields | Strong outside fields can demagnetize magnets. I use high-coercivity grades or shielding when needed. |

Sometimes, I notice magnets lose power if they get too hot or wet. Chips and cracks happen if I drop them or use them in vibrating machines. I always store magnets carefully and check for damage before each use.

Osenc helps me avoid these problems by offering magnets with tough coatings and precise engineering. Their technical support gives me advice on choosing the right magnet for any environment.

⚠️ Note: Always match the magnet to your job’s demands. If you need extra protection, ask about custom solutions from Osenc.

I find that understanding these pros and cons helps me pick the best magnet for every task. Holding magnets make my work easier, but I stay aware of their limits to keep things running smoothly.

A holding magnet is a tool that grips metal objects with powerful magnetic force. I use them to make work safer and faster. In manufacturing, magnets boost efficiency and safety:

| Feature | Description |

|---|---|

| Built-in Safety Factor | Lifting capacity exceeds load weight for extra safety. |

| Streamlined Operations | Quick lifting reduces time and effort. |

| Reduced Safety Risks | No need for chains or slings. |

When I pick a magnet, I always check strength, surface, and safety. Osenc helps me find the right fit for every job. If you ask me, a holding magnet is the secret to secure and easy metal handling. 🧲

FAQ

What is the main purpose of a holding magnet?

A holding magnet grips and secures metal objects using magnetic force. I use them to hold, lift, or position items safely and quickly. They make my work easier in both industrial and home settings. 🧲

How strong are neodymium holding magnets?

Neodymium holding magnets can be up to 30% stronger than ceramic magnets. I trust them for heavy-duty jobs. Their compact size packs a lot of power, making them my top choice for demanding tasks.

Can I use holding magnets outdoors?

Yes, but I choose magnets with protective coatings for outdoor use. Moisture and weather can cause rust. Osenc offers magnets with special coatings that help prevent corrosion, so I don’t worry about rain or humidity. 🌧️

Are holding magnets safe around electronics?

No, strong magnets can disrupt or damage electronics. I always keep them away from phones, laptops, and credit cards. If I work near sensitive devices, I use extra caution to avoid accidental damage.

How do I choose the right size magnet for my project?

I match the magnet’s size and shape to the weight and space available. For heavy loads, I pick larger or heavy-duty magnets. For tight spaces, I use micro or custom-shaped magnets. Osenc helps me find the perfect fit every time.

What maintenance do holding magnets need?

I keep magnets clean, dry, and free from rust. I check for chips or cracks and store them safely. Regular care helps maintain their strength. I avoid dropping them to prevent damage. 🧼

Can I get custom holding magnets for unique needs?

Yes, custom holding magnets are available for special projects. I work with suppliers like Osenc to design magnets that fit my exact requirements. Custom solutions help me solve tricky challenges.

What are common uses for holding magnets at home?

I use holding magnets for organizing, securing, and DIY projects. They keep cabinet doors shut, hold tools on racks, and even secure tablecloths outdoors. Their versatility makes them handy in every room. 🏠

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.