Magnetic fields are powerful forces that are applied in science, industry, and everyday life. However, when they cling together, their strength makes it difficult for them to part. It does not matter whether you have small magnets, heavy neodymium magnets, or magnets in devices; the issue remains: how to easily and safely remove them. This guide provides realistic tips, equipment such as magnet splitters, and step-by-step directions to part magnets without harm or destruction.

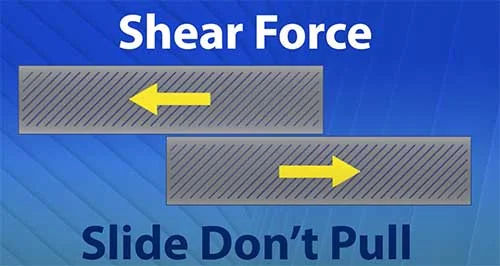

If you only read one thing, read this: don’t pull straight. Most magnets separate faster when you slide them sideways first, then add a spacer.

Quick method:

- Put on gloves and safety glasses.

- Hold one magnet still and slide the other sideways.

- As soon as you see a tiny gap, insert a plastic/wood shim from the edge.

- Keep sliding and adding shims until they separate, then store them with spacers.

Why Magnets Stick Together (And Why Some Repel)

Why do magnets stick together, and why do magnets push away from each other? It depends on how the poles line up. Opposite poles attract and lock together, while like poles repel. The problem is that once two strong magnets make full contact, the attraction becomes “all surface area,” so separating them feels much harder than you expect.

That’s why the techniques in this guide focus on reducing contact first—sliding, peeling, and spacing—rather than trying to overpower the pull.

How To Separate Magnet Easily

Removal of magnets, particularly powerful or rare-earth magnets, takes time and proper skill. The key rule is simple: don’t pull straight—slide first. Direct pull is hardly ever effective because it keeps the full contact area locked together. Sliding, peeling, or inserting shims reduces contact and makes separation much easier and safer.

These are the primary steps to take for the safe separation of the magnets. Follow these steps to separate magnets safely.

Ensure safety first

Magnets can shatter or chip, so it’s very important to put on gloves to shield the hands and safety glasses to protect the eyes.

Shim or non-magnetic separator

Once you create even a tiny edge gap, insert a sheet of plastic, wood, or acrylic from the edge. This loosens the grip fast and keeps your fingers out of the pinch zone.

Apply a sliding motion

Slide one of the magnets sideways, not straight away from the other. This gradually weakens the hold without a sudden snap.

Use tools or fixtures

Clamp one of the magnets in a vise holding wooden jaws or padded pliers. This gives you control and prevents the magnets from jumping.

Work incrementally

Add more shims at the edges and keep sliding until the magnets separate.

Control and finish

Once separated, store magnets with spacers to prevent them from snapping back together. If you do this often, it’s worth keeping a splitter/separator tool nearby so you can repeat the process safely.

Are Small Magnets Easy To Separate?

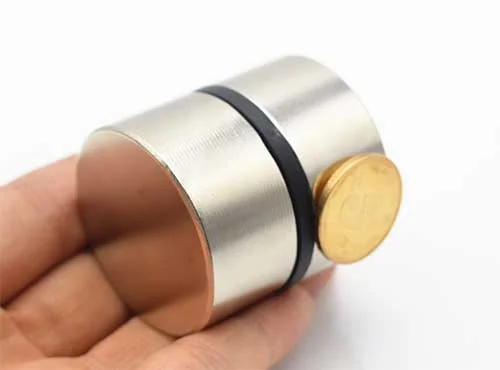

Not really, no. You might assume that it is only larger magnets that tend to get stuck together, but it can happen with smaller magnets as well—which is why Separating Small Sized Magnets can still catch people off guard. The reason is that the size of the magnet has less of an impact than the actual strength of a magnet.

You could take two very large, weak magnets and find that you can separate them with your fingers easily. Take two tiny magnets with a large level of power, though, and you could find they are near-impossible to separate with your fingers.

The strength of a magnet is determined by far more than just how large it is. If you assume that bigger magnets equal more power, then you could be in for a shock when you find that your magnets are locked together.

To help you avoid that particular issue, we have put together an easy-to-follow guide on how to separate magnet.

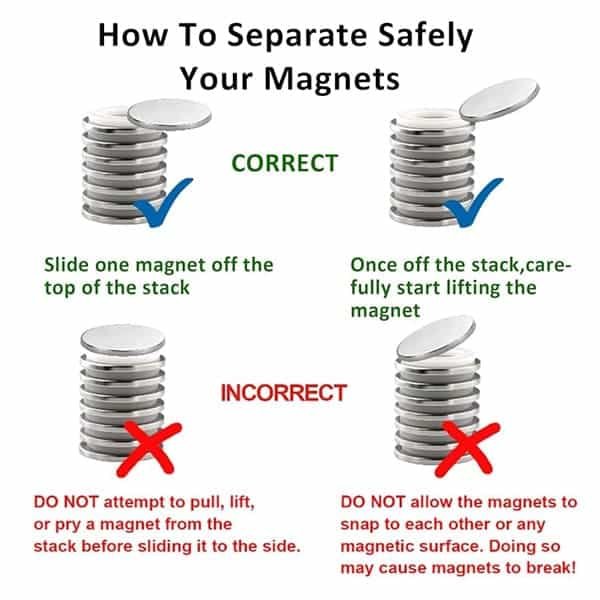

How to Separate Small Magnets Without Scraping Your Fingers

Small magnets can be tricky because they’re easy to grip the wrong way. If you try to pinch and pull them apart, they’ll feel “glued” together and you’ll scrape your fingers. The safer move is to separate two magnets using a controlled slide.

Here’s the simple method for small stacks:

- Keep the stack flat on a table so it can’t jump.

- Hold the bottom magnet still.

- Slide the top magnet off the stack sideways, then lift it away only after it has moved past the strongest point.

- If your nails keep slipping, use a thin plastic card from the edge to start the motion.

The Magnet Size Really Does Matter

The most practical way to separate magnets is to match the method to the pull force. If you try to use the same technique for every magnet, that’s when fingers get jammed and magnets chip.

If you are trying to separate smaller magnets – something with a maximum of around 5lbs of force – then you should find they come apart with relative ease. Most of the time these should not resist one another too much and thus should be able to split apart simply by using the sliding technique that we have listed below.

However, for those dealing with a medium-sized magnet – something up to around 11lbs of pull force – you should focus heavily on using a separator. We highly recommend that, if possible, you keep some kind of separator as noted below. This little washer or spacer will make sure that you are not going to run into the same problems as you would expect when separating the magnets.

A higher range of pull power means that you always need to be careful when you are removing the magnets. Snapping together can become very painful, and in higher strength magnets could lead to physical injury.

Anything in excess of 12-25lbs and beyond, though, must be taken care of with excess precision, because most of them are large magnets with very big pull forces. Stronger magnets need a little leverage to introduce the gap, so you should plan to wedge them apart (as we’ll explain next) instead of relying on raw grip strength. You should always make sure that you get the magnets as far apart as possible before you try and remove then with your hands.

Larger magnet pulling powers should even be taken apart using a magnet splitter, if you have one—this is one of the safer ways to quickly and easily separate larger and stronger neodymium magnets without chipped edges or pinched fingers.

Pull Force Cheat Sheet: What Method to Use

A practical rule is this: the stronger the pull force, the more you should rely on sliding and spacing, not grip strength.

Quick cheat sheet:

- Up to about 5 lbs: sliding is usually enough.

- Around 5–11 lbs: plan to use a shim early, not “after it hurts.”

- Around 12–25 lbs: make a gap first (table edge or wedge), then slide.

- Above that range: use a controlled tool setup, because a snap-back can chip the magnet or jam fingers.

What is a magnet splitter?

A magnet splitter is a tool or device designed to separate two magnets (or a magnet from a ferrous surface) safely, especially when the attraction between them is strong. In other words, use a separating device known as a magnet splitter or separator jig to gain control and reduce the chance of a sudden snap. It usually provides mechanical advantage (leverage) or a guided path that reduces the required force by leveraging sliding, twisting, or levering motions rather than pure pulling.

When to Use a Magnet Splitter (And How to Do It Safely)

When should you use a magnet splitter? Use it when the magnets are large, very strong, or stacked—basically anytime you can’t control the movement with calm hands. It’s also a good idea when you need to remove a strong magnet from metal and you don’t want it to jump back.

Basic safe workflow:

- Fix one magnet so it cannot move.

- Guide the other magnet to slide away along a controlled path.

- Keep your fingers away from the join line at all times.

- Stop and add a spacer as soon as a gap appears, then finish the separation slowly.

Principle

The magnet splitter principle consists of transforming the pulling force into a moving or tilting motion. When the magnets stick together, they are in contact with one another, providing a high degree of attraction. A splitter decreases the size of contacts and allows for extracting or tilting in

small steps. It is also levered or a slide that provides you with additional strength than you can obtain by hand, hence you require less power. The magnet splitters commonly consist of non-magnetic materials such as aluminum, plastics, and wood. This prevents the magnetic field from changing. In industrial models, the guides ensure that the magnets travel in a harmless manner, such that they do not break or get stuck.

Uses

Magnetic splitters are very useful in different fields. Some of the uses are as follows

Industry maintenance and production

Generally, in motors, generators, and sensors, the magnets are attached. A splitter has a way of allowing technicians to extract them without destroying other components.

Magnet research and recycling

Labs have splitters to construct and deconstruct magnetic arrays to be tested. They are recycled by plants to extract magnets from old devices.

Educational uses

In research laboratories or schools, splitters are used to make magnet demos safer by regulating the forces.

Speaker and electronic repairs

A splitter is used to extract magnets in a device without damaging the coils and circuits when disassembling devices with magnets. (Related: Speaker And Speaker Magnet)

Getting Started With Separating Magnet

So, the first thing that you should probably look at when you want to get a magnet to separate is to get used to the very basics. Any magnet you wish to remove should be slid not pulled. Many people try to use all of their physical strength to pull the two magnets apart. Do that, though, and you simply run the risk of hurting yourself. With two magnets – especially powerful magnets like neodymium magnets – stuck together, you are in no position to pull them apart.

Instead, you need to use a sliding technique that we will try to explain below. This should make it much easier for you to be able to split apart the magnets in the future.

Sliding Your Magnets Free From One Another

So, the best way to make sure that you can get the magnets to separate is quite simple—you should slide them apart. If you can, place the magnets on a flat surface and slide them apart horizontally so the force stays controlled and your hands stay out of the pinch zone. By sliding a magnet across one another, it is much easier to get the magnetic connection to loosen and thus make it easier to actually pull apart said magnets in the first place.

Try to keep that in mind, as many people will find that pushing a magnet and sliding it alone is much easier than trying to pull. Why? Because magnet strength is managed and determined by their pull power. If a magnet is able to be pulled apart then it is not very strong. Magnet movements are made easier by large multiples if you simply push the magnet into the other magnet and then slide.

Smaller magnets should slide apart with relative ease, even if you are not able to get some kind of spacer in there to separate the magnets. Larger magnets might need you to push down and then slide the magnet with both hands, though!

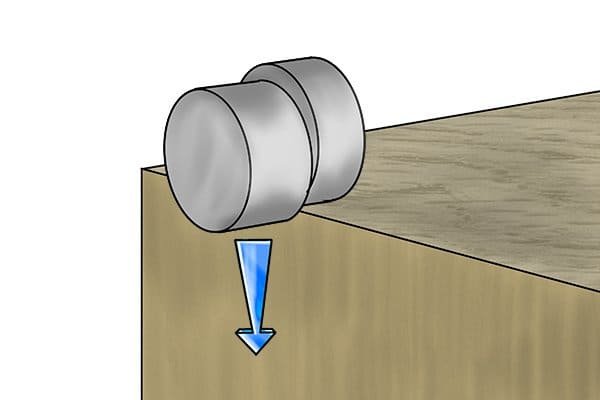

Want To Separate Magnet Easily? Create A Gap!

One of the most common issues when learning how to separate magnets is to form the edge you need. Magnets of a particularly high strength will often need you to produce some form of gap and leverage for you to open them up. Place the two magnets on the edge of a table (non-metallic surface only), then work the join line carefully so you can create a controlled opening for a shim.

To do this safely, think in steps:

- Insert a plastic/wood spacer immediately, then keep sliding.

- Put the joined edge right on the table edge (non-metal surface).

- Press down to control the magnets so they don’t jump.

- Push the top magnet sideways until a small gap appears.

Make sure that when the magnets give way that you separate quickly, as they could quickly re-connect. This could lead to fingers getting jammed, causing yourself unneeded pain and discomfort.

Creating A Wedge

In some cases, you might find that two magnets are simply too strong to separate using the conventional means that we have explained above. If you find yourself in that position, you might need to employ a few tools to split them apart.

The best place to start with that in mind would be to use a wedge that could pull them apart. We recommend you use something like a wooden wedge that could be placed in-between and used as a means of forcing a gap. These wedges, though, might need the strength of more than one person to ensure you can create the gap to separate your magnets.

You should therefore always look to make sure that you use wedges with the help of someone else. The strength of the magnets means that you could easily snap or crush your fingers/hands if you are not being careful. By having two people, you can then focus on prying the magnets apart, only dropping your fingers in when it is absolutely necessary.

You should wear gloves and you should wear safety goggles for your eyes, too, as magnets can be surprisingly easy to snap off and break. If the magnets reconnect during the removal process, this could see a part of the magnet snap off and become like shrapnel, so both eye and hand protection is essential.

How to Remove a Strong Magnet From Metal

Removing a strong magnet from metal is similar to separating two magnets: don’t pull straight. Straight pull keeps the contact area fully engaged and the magnet will “cling” harder than you expect.

Use this method instead:

- Start at one edge and introduce a thin non-metal spacer (plastic or wood).

- Pry just enough to create a small gap—don’t force it.

- Once you have that gap, slide the magnet sideways to peel it off the surface.

- Keep control of the magnet as it comes free, because it can jump back instantly.

Storing Your Magnets

If you are using magnets that are as strong as neodymium magnets, then you should probably look to use the storage siders you are given. Most neodymium magnets will come with a little piece of card or plastic that is kept between the magnets. If you keep this piece of card then you can easily store the magnets together, but not on top of one another. By keeping that little sheet of plastic/card in-between, you make it much easier for the magnets to stay separate to one another.

These little spacers should always be determined by magnet thickness, though. A very strong magnet could easily still connect to something even if it is separated by a piece of paper or thin card. The stronger the magnet, the thicker and stronger the spacing item has to be. Naturally, you cannot use any metallic spacers; something made from heavy card and/or plastic is the right choice.

What happens if you cut a magnet in half

People also ask what happens if you cut a magnet in half. In most cases, you don’t get “one piece that is only north” and “one piece that is only south.” You usually end up with two smaller magnets, and each piece still has its own north and south poles.

The bigger concern is safety and damage. Many strong magnets (especially neodymium) are brittle. Cutting, snapping, or grinding can create sharp fragments and dust, and the magnet may chip, crack, or lose performance. If your goal is simply to separate magnets, cutting is the wrong approach—sliding, shims, and controlled tools are safer and more reliable.

Last Word

The magnets are sometimes difficult to pull apart; however, it is possible to pull the magnets apart by sliding or peeling them with the help of the appropriate tools. Wear safety gear, never hurry, and keep each magnet with spacers. With the right tools like shims, clamps, and magnet splitters, and with care, separating magnets can be done safely without damage to the magnets or injury to yourself.

Refer:

https://www.cobbk12.org/magnet-programs

FAQ

Below are quick answers to the most common questions about separating magnets, especially when magnets are stuck together or too strong to pull apart.

How to separate two magnets?

The following is a fast method for separating two stuck magnets.

- Wear protective glasses and gloves.

- Add a plastic/wooden shim on the edge.

- Move one of the magnets across the other.

- Work at the sides until an opening is made.

- Pull them apart slowly.

How to separate two magnetic disks?

These are the measures for separating magnetic disks without damaging them.

- Lay one disk flat upon a surface.

- Insert a thin card or a sheet of plastic at the edge.

- Gesture until the upper disk begins to rise.

- Work the shim around the disk.

- Take the top disk off when it has loosened.

How to separate two neodymium magnets?

These are the steps to take in order to separate two neodymium magnets.

- Lay the magnets on a smooth surface.

- Hold the two magnets in your hands, and twist one clockwise and the other counter clockwise like you’re turning a dial.

- Continue the rotation until the magnets begin to separate, then transition into sliding to finish the job.

- Slide the top magnet towards the bottom one when a lesser resistance is felt.

- Validly get it straight and place it aside with a cushion.

How to separate strong magnets?

Perform these simple steps to separate strong magnets.

- Place the magnets on a non-metal table.

- Place a massive block of wood on one side of the upper magnet.

- Use a rubber mallet to tap the block lightly to slide the magnet.

- Repeat the same till the magnets slide apart.

- Take them out carefully one by one.

How to remove a strong magnet from metal?

Use these simple steps to remove a strong magnet from metal.

- Wrap the magnet with a strong string or a cord.

- Attach the other end of the cord to something.

- Use the other end to provide a lever to the magnet.

- Slowly, the magnet will begin to separate the metal.

- Get it as soon as possible lest it spring back.

How is magnetism used to separate mixtures?

Magnetism can separate mixtures by attracting magnetic or ferrous particles and leaving non-magnetic substances behind—this is separating magnetic materials from non-magnetic materials. For example, in mining, crushed ore passes near magnets; iron bits are pulled out while rocks remain. In recycling, magnetic drums remove steel from shredded waste. This process is used in virtually all process industries because it’s fast, scalable, and doesn’t require complex sorting.

How to separate magnets stuck together?

Separate the magnets by a thin non-metallic material such as plastic or wood. Now pull one of the magnets, not straight. This prevents the magnets from sticking so much and allows you to open them safely.

How to separate iron filings from sand without a magnet?

You may utilize static electricity. Charge the plastic rod/balloon by rubbing and place it close to the mix. The filings will be attached to the rod and abandoned in the sand. Or water may be used, and the filings will sink or float.

How to separate a magnet from metal?

Start splitting them apart by placing an object that is not magnetic (plastic or wood) between the magnet and the metal. Then slide or pry at one edge, taking your time until you may safely remove the magnet.

How to separate magnetic lashes?

Have the two ends of the false lashes in hand and push the layers of the top and bottom sides apart. Do this slowly to avoid bending or breakage. Plastic tip tweezers can help reduce the pain, and the lashes can be reused.

How to separate the magnet from the speakers?

Firstly, take the speaker out. Unscrew/unclamp the frame, and locate the magnet. Insert a sliding wedge or a pry tool that does not contain any metals under the magnet and slide it up gradually. Do not break the coil and other components.

How to separate the magnet on a Sleep Number bed?

Unplug the bed first. Locate the position of the magnet, most often in a bracket or plug. Take out the screws or clips that secure it. Slide out the magnet with a plastic object very slowly, so as not to break the frame.

How to separate rare earth magnets?

These are very powerful magnets. Put on gloves and fix one magnet. Place a shim of wood or plastic on its edge, straighten the other magnet sideways, and the pull is broken. Never pull straight. When a gap appears, drag the top magnet out slowly without rushing it so that it does not bounce back and break.

How to separate small magnets?

Small magnets are less difficult but must be treated with caution. Carefully keep one of them in place, then Use your fingers to slide the top magnet off the top of the stack (or use a non-metal separator from the side) instead of pulling straight up.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.