Neodymium magnets, also known as NdFeB magnets, are the strongest permanent magnets in the world. Many of the things we use every day, such as speakers, motors, electric cars, computer hard drives, and wind turbines, are made with them. It is not an easy task to make them, especially since it involves a combination of science, heat, and delicate engineering. So, in this article, we will go into the interesting process of making these magnets. (Related: What Is A Neodymium Magnet)

How Are Neodymium Magnets Made?

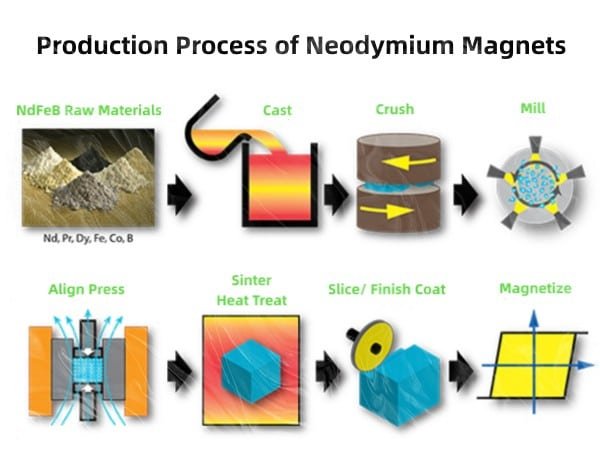

The process of making a neodymium magnet is as follows.

Step 1: Mine the rare earth metals

It begins way down in the ground. Neodymium is a rare earth element commonly occurring in minerals such as bastnäsite and monazite, and usually together with other rare earths like praseodymium and cerium.

The ore is mined and crushed, followed by a chemical treatment to obtain neodymium oxide (Nd₂O₃). The refining process is done through solvent extraction and ion exchange in separating pure neodymium and other elements.

Due to the fact that the majority of neodymium is mined and refined in China, the nation controls the production of magnets in the world. The extracted oxide becomes the key ingredient for the powerful alloy that forms neodymium magnets.

Step 2: Melting

Then, neodymium oxide is mixed with iron (Fe) and boron (B) – the three elements which constitute the Nd₂Fe₁₄B compound. A vacuum induction furnace is used to melt these ingredients together so that they are not oxidized.

The temperature surpasses 1300°C to form a homogeneous molten alloy. It is melted down and then quickly cooled into ingots or flakes. This alloy is used as the basis of a powerful magnetic material for the future.

Step 3: Milling

Solid alloy is then reduced to a fine powder by jet mills or ball milling. This is an important step since the magnetic properties are determined by the presence of ultra-fine and well-sized particles, which are usually a few microns wide.

Milling is carried out in an air-free environment as the powder of neodymium reacts rapidly with air or moisture. The resulting powder is the ideal one to press and shape during the next step.

Step 4: Pressing

Pressing is done on the fine powder to shape it. In the process of pressing, the manufacturers usually impose a magnetic field to orient the small particles in a single direction, which can define the future attraction and repulsion of the magnet.

Two methods are common:

Die pressing: presses the powder against a mold in one way.

Isostatic Pressing: The pressure is used in every direction and is applied equally to achieve a more homogeneous density.

Once pressed, the magnet acquires an invisible but visible shape called a green compact. It is yet weak, but prepared to sinter.

Step 5: Sintering

One of the most crucial stages is sintering. The green compacts are heated in a vacuum furnace at approximately 1000-1100°C. At this temperature, the particles bond together without melting, turning into a dense, solid block.

This enhances the strength, hardness, and stability of the magnet. This process improves the magnet’s strength, hardness, and stability. After sintering, the magnet’s structure becomes uniform, and its density increases to nearly its theoretical maximum. The Nd₂Fe₁₄B crystal phase has now been completely formed- the main source of such strong attraction of the magnet.

Step 6: Annealing

The magnets are then annealed, i.e., heated once more to approximately 500–600°C and then allowed to cool gradually. This reduces internal stress and enhances mechanical stability.

Annealing is also used in enhancing the magnetism, and thus the magnets become less susceptible to demagnetization and temperature changes. In the absence of this step, any little amount of stress or heat might break or weaken the magnet.

Step 7: Machining

The sintered magnets, after cooling, are then formed into final shapes by diamond-coated grinders or wire EDM (electrical discharge machining).

Since neodymium magnets are extremely hard yet brittle, they can’t be cut with regular tools. Careful machining needs to be taken to avoid cracking or overheating of the machined part to reduce the magnetic strength.

The magnets at this stage are shaped into common objects such as discs, rings or blocks, as per future use.

Step 8: Plating

Neodymium magnets are powerful but also vulnerable — they corrode easily. To safeguard them, they are shielded with metals like nickel, copper, zinc, gold, or epoxy.

The most used coating is the Ni-Cu-Ni (Nickel-Copper-Nickel) as it offers excellent corrosion resistance and a smooth finish. The coating can be done through electroplating or E-Poxy spraying.

This coating is a shield, and it prevents the magnet from being wet or oxidized, which makes the magnet operate longer.

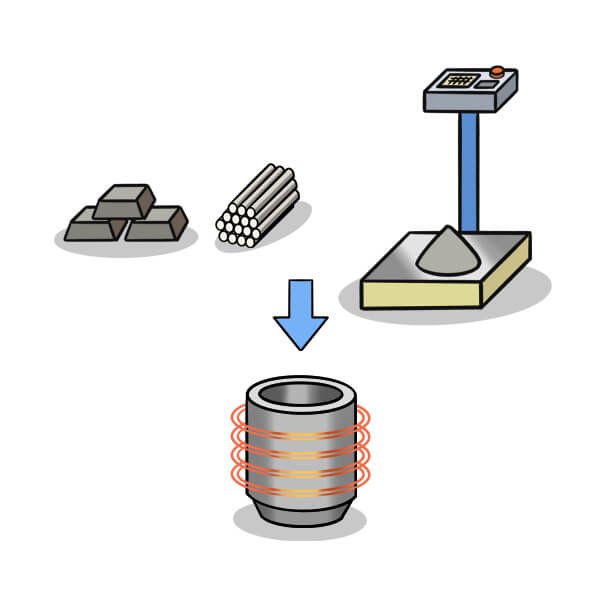

Step 9: Magnetizing

To this point, the magnets are not actually magnetic. They have to be magnetized with a very strong electromagnetic pulse.

The magnet is inserted into a coil, and a high intensity (but short) current produces a magnetic field (around 3–5 Tesla). This discipline compels the magnetic domains within the magnet to be lined up in one direction, and this endures, giving it the strength of a magnet.

After the magnet has been magnetized, it is checked for consistency, strength, direction, and then packed.

Related:

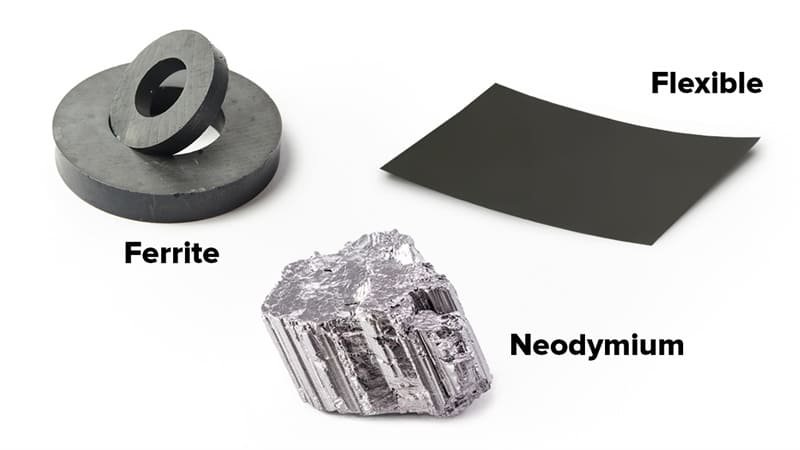

What materials are used to make neodymium magnets?

Neodymium magnets are primarily made of neodymium, iron, and boron, but often include trace elements for better performance:

• Neodymium (Nd): The element essential to the core that gives high magnetic characteristics.

• Iron (Fe): Provides structure and gives it durability.

• Boron (B): Assists in the formation of Nd₂Fe₁₄B crystalline compound.

• Dysprosium (Dy) or Terbium (Tb): Occasionally used to make it resistant to heat.

• Protective coatings: Nickel, zinc, or epoxy will stop corrosion.

A combination of all these ingredients forms an ideal balance of strength, stability, and resistance.

How are rare earth magnets produced?

Other rare earth magnets, such as neodymium and samarium-cobalt magnets are manufactured in the same manner: melting, milling, pressing, sintering and magnetizing.

The major distinction is in their material structure and thermal character. Neodymium magnets are stronger but more sensitive to heat, while samarium-cobalt magnets perform better at higher temperatures.

Both types require precise control over each step to achieve maximum strength and uniformity.

How does sintering work in magnet manufacturing?

The process of sintering is the diffusion process; the fine powder particles are warmed until they fuse. The heat results in the movement of atoms between the particle boundaries and closes the gaps to form a solid and thick material.

This is done under vacuum to avoid oxidation. What comes out is a powerful, small, and stable magnet. The material would not have been strong enough to contain the energy of a magnet and would not have been porous without sintering.

How are neodymium magnets magnetized?

The process of magnetization occurs in a special magnetizing coil. A magnetic pulse, which is short and intense, aligns the internal domains of the magnet.

When properly aligned, the magnet stays in that way, unless it is subjected to extremely high temperatures or powerful counter-magnetism. It is in the process that the magnet gets its strong and permanent pull.

How are neodymium magnets coated or plated?

Coating protects neodymium magnets from corrosion. Common coatings include:

Nickel-Copper-Nickel (Ni-Cu-Ni): Offers a bright and long-lasting finish.

Zinc plating: It provides moderate protection and is bluish in appearance.

Epoxy coating: Suited to humid conditions.

Gold plating: It is applicable in decorative or medical applications as it is biocompatible.

Each coating is applied either by electroplating or by spraying, and ensures that the magnet will last several years without rusting.

What machines are used in magnet production?

High-precision industrial machines are used to manufacture magnets, and these include:

- Alloy melting vacuum furnaces.

- Grinding in jet or ball mills.

- Powder compacting hydraulic presses.

- Sintering bonding furnaces.

- Annealing ovens for stress relief.

- Shaping is done on diamond grinders and EDM machines.

- Several coating electroplating units.

- Magnetizing coils for charging final magnets

All machines have different functions in ensuring consistency and quality.

What affects neodymium magnet quality?

The strength and quality of neodymium magnets depend on several important factors:

- Material purity: Even small impurities can lower the magnet’s performance.

- Particle size: Finer, evenly sized particles create stronger and denser magnets.

- Sintering control: If the temperature or timing is off, the magnet can crack or lose strength.

- Composition ratio: The right balance of neodymium, iron, and boron determines the magnet’s grade and power.

- Coating quality: A strong, even coating prevents corrosion and extends the magnet’s lifespan.

- Magnetizing strength: Using a powerful magnetic field ensures the magnet is fully charged.

Each step needs careful attention to produce magnets that meet top-quality standards.

Wrapping Up

Neodymium magnets are a result of precision, heat, and chemistry — from mining rare earth metals to pressing, sintering, plating, and magnetizing. Every single stage makes raw materials into one of the most powerful forces of modern technology. Our devices, our cars, and our renewable energy systems cannot operate without these magnets, which is evidence that a small amount of metal can produce a world of power.

Related:

How Strong Is a Neodymium Magnet

Where to Buy Neodymium Magnets

FAQs

Are neodymium magnets environmentally friendly?

Not entirely. Mining and refining rare earths cause pollution, but modern recycling and cleaner refining methods are reducing environmental impact.

How are rare earths recycled in magnet production?

Old or defective magnets are demagnetized and chemically processed to recover rare earth metals, which are reused to make new magnets.

How to increase the neodymium magnet strength?

Use high-quality alloys, add small amounts of dysprosium, improve sintering, and ensure proper magnetic alignment.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.