The strongest types of permanent magnets are neodymium (NdFeB) magnets used in motors, sensors, and tools. However, their strength has a disadvantage, which means that they rust readily. They are porous and contain a lot of iron; hence they readily exhibit oxidation when exposed to air or water. When you understand how rust develops, it’s easier to prevent it and extend magnet life.

Why NdFeB magnets can rust?

Neodymium magnets are very sensitive to moisture and oxygen. In the absence of protective plating, the corrosion begins rapidly and degrades the surface and the strength.

What neodymium magnets are made of? (Nd-Fe-B core + porous microstructure)

The core and microstructure are porous (Nd-Fe-B core + porous microstructure). These magnets are made of neodymium, iron, and boron and are porous due to sintering. Minimal cracks hold moisture, which results in internal rust when uncoated.

Why iron content + porosity = Corrosion risk without protection?

Humidity combines quickly with iron, and the pores of the magnet allow the moisture to diffuse inside. This leads to pitting and flaking and therefore uncoated NdFeB magnets are very susceptible to corrosion especially in wet or marine environments.

Does rust weaken a magnet?

Yes. Rust directly weakens a neodymium magnet by damaging its surface and lowering magnetic output. Corrosion shortens lifespan and reduces performance over time.

Demagnetization at the surface and loss of working flux

When rust forms, it breaks the smooth magnetic lines of flux, causing localized demagnetization. Affected areas lose pull force first, reducing overall field strength and efficiency, especially in precision uses like sensors or motors.

When corrosion becomes irreversible vs. recoverable?

Early rust can sometimes be cleaned and stabilized. But once corrosion reaches the magnetic grains, the loss is permanent. The structure changes, making full re-magnetization impossible, and replacement becomes the only option.

Common corrosion triggers

The neodymium magnets are very reactive and can easily rust in the presence of moisture, salt or adverse weather conditions. The knowledge of these corrosion triggers can be used to choose the appropriate coatings and maintenance techniques.

Saltwater and high-chloride environments

Neodymium magnets are easily corroded by exposure to toxic saltwater or air with a high content of chlorides. Protective coats are broken by chloride ions that reach the metal surface and cause oxidation.

High humidity, sweat, and condensation cycles

Magnets kept in rainy temperatures or touched with wet hands are subjected to constant dampness. The repetition of the condensing and drying process promotes rusting in edges or micro cracks even when under protection layers.

Heat + moisture (accelerated oxidation)

Oxidation accelerates tremendously when there is heat and moisture present. The high temperature causes the coating pores, which admit oxygen and water vapor to the metal core and enhances corrosion activity.

Mechanical damage that cracks coatings

Magnet coating can be chipped or scratched by physical impact or friction. When damaged, the exposed iron surfaces oxidize instantly, spreading the corrosion below the plating and undermining the strength and outlook.

Coatings that resist rust

The core materials in the neodymium magnets are easily oxidized by the presence of moist air or salt; hence, effective protective coating is needed. The coating serves as protection between the magnet and the surroundings, and it does not allow oxygen and water to get in touch with the magnet.

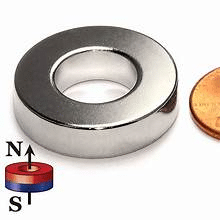

Ni-Cu-Ni (nickel) plating

A nickel, copper, and nickel triple layer coating is the most common on the neodymium magnets. It provides a bright metallic finish, good corrosion resistance and medium hardness. But when the coating cracks or chips, the moisture will be able to enter the core, and rusting will begin.

Zinc plating

Zinc plating offers a matte gray finish, which has excellent adhesion but poor corrosion resistance. It is cheap and appropriate in dry indoor environment, and in wet or sea environment, it can corrode quicker than nickel finish.

Epoxy (Black/colored)

The epoxy coatings are a smooth, colored, and waterproof film produced in an area surrounding the magnet. They have excellent resistance to chemicals and durability. Epoxy can be used when it is wet or even outdoors, but might scratch when it is handled roughly.

Parylene / PTFE/ Polymer encapsulation

These coatings create a thin, smooth polymer layer that is chemically inert and highly moisture resistant. Parylene and PTFE have medical, marine or food applications where it is important to be totally insulated against both air and water.

Stainless steel shell and fully sealed housings

Covering magnets with stainless steel or putting them in sealed cases keeps out water and air, stopping rust and damage completely.

How to prevent rust in use?

To maintain the neodymium magnets without corrosion, proper handling and storage are major requirements. The choice of the appropriate coating and the safeguarding of moisture is the guarantee of the long-lasting functioning of the piece in hard conditions.

Choose the right coating for environment (indoor, outdoor, marine, food)

Find the matching coating to the conditions of use. Nickel is used indoors, epoxy or PTFE in wet and moist environments and stainless steel is used in marine or food grade application.

Fully encapsulate and pot magnets for wet applications

When used in humid or submerged conditions, it is possible to seal magnets inside epoxy resin, rubber, or plastic covers to prevent water infiltration. This helps in the away oxidation, increases life expectancy and maintains the magnetic performance.

Avoid edge chipping: handle with spacers and soft contact surfaces

Weak points are being coated in with edges. Insert spacers, foam covers, or soft liners to avoid impacts and scratches that reveal the metal and precipitate the development of rust.

Dry, ventilated storage with desiccants; bagging and VCI options

Keep the magnets of a store in a low-humid and well-ventilated place. Use silica gel, VCI bags or sealed pouches to prevent corrosion by absorbing the moisture during shipping or long-term storage.

Waterproofing and encapsulation methods

Neodymium magnets are only able to withstand exposure to moisture when sealed. Waterproofing provides an external coating, which prevents humidity, condensation, and contact with chemicals, guaranteeing long-term stability and strength.

PVC/TPU overmolding and plastic sleeves

Covering neodymium magnets with PVC or TPU adds a waterproof and flexible layer. These plastic coatings seal out moisture, protect against scratches, and make magnets safer to handle in wet or outdoor conditions.

Epoxy potting and two-part resins

Epoxy is used to encapsulate the magnets in a water-tight hard shell. Two-part resin systems close the cracks and borders, thus making them suitable in sensors, under-water motors, and equipment that are constantly in contact with wetness.

Rubber/ silicone over-coats for impact + moisture

Impact cushioning and humidity blocking are performed by rubber or silicone layers. They are flexible, protective, and increase the magnet life when subjected to vibration, motion, or moist high-friction temperatures.

Corrosion testing and standards

Corrosion testing will make sure that the neodymium magnets can endure adverse or wet conditions without being weakened. It assists manufacturers in verifying the validity of coating and protective layers.

Saltspray / salt fog (ASTM B117) basics

ATM B117 test subjects coated magnets to a controlled salt mist during hundreds of hours. This is a quicker test that mimics years of exposure to salty air or marine conditions, and it assists in the testing of the effectiveness of such coating as nickel or epoxy against corrosion damage.

Humidity and cyclic corrosion tests (overview)

The humidity and cyclic corrosion tests are interchanged by wet, dry and warm conditions to simulate weather change conditions in the real world. Such cycles allow the identification of micro cracks or weakening of the coating before it is used in the field, and it is a more valid performance analysis than the simple statical tests.

Maintenance and troubleshooting

Regular cleaning ensures that the magnets are not rusty and that they last longer. Corrosion on the surface can be checked by timely inspection and drying before spreading and interfering with magnet performance.

Early signs of coating failure and what to do?

Coating failure is characterized by discoloration, bubbling, or dull spots. When observed, wipe the surface with a clean cloth, keep the magnet dry, and apply a corrosion inhibitor/sealant at once to prevent oxidation.

Cleaning, drying, and safe storage after exposure

When in contact with water, wipe dry magnets with a soft cloth. Keep them in a low-humidity well ventilated place, ideally with desiccant or VCI bags. Do not pile them up roughly; this will chip or coat the cracks.

Conclusion

Corrosion should be prevented as this would safeguard the strength, appearance, and life of neodymium magnets. Not only do proper coatings, handling and maintenance prevent rust, but they also provide consistent performance of the magnet across the industrial, marine and ordinary applications.

FAQs

Will neodymium magnets rust in fresh vs. saltwater?

Yes, the two are both corrosive; however, saltwater rusts at a high rate because of chloride ions.

Are “waterproof” neodymium magnets truly waterproof?

It is only waterproof when completely encapsulated; it is not entirely waterproof when just coated.

Can a rusted magnet be restored?

Rust on the metal can be washed; however, deep rust makes it weaker.

Do ceramic or samarium-cobalt magnets rust?

No, they are more resistant to oxidation, as they do not have any raw iron materials.

How long will a neodymium magnet lasts?

It can take decades until it decays, in case it is well coated and stored.

What are the disadvantages of neodymium magnets?

They are easy to corrode, are brittle, and weaken at high temperatures.

How to keep a magnet from rusting?

Apply thick coatings, keep it dry, and put it where it will not be touched by any material.

Will a neodymium magnet rust?

Yes, it will rust unless it has a good protective coating or is completely sealed.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.