The cost of Micro magnet

Costs For Micro Neodymium Magnets

People are curious why micromagnets are more expensive than ordinary magnets. The production of miniature magnets consumes much less material than ordinary magnets.

Is it the manufacturer who makes a high profit?

No, here are three reasons why miniature neodymium magnets cost more.

Hard To Process

Micro magnets are harder to produce mostly because they are too small to handle properly. They will require special fixtures and additional attention. Cutting and coating are the biggest challenges. It can take more time to adjust and finetune machines. In some extreme cases, it takes us 7 hours of manual work before we can produce the first qualified micromagnet.

Most of the procedures require manual processing for the magnets, resulting in lower productivity. This also adds to the production cost.

High Wastage

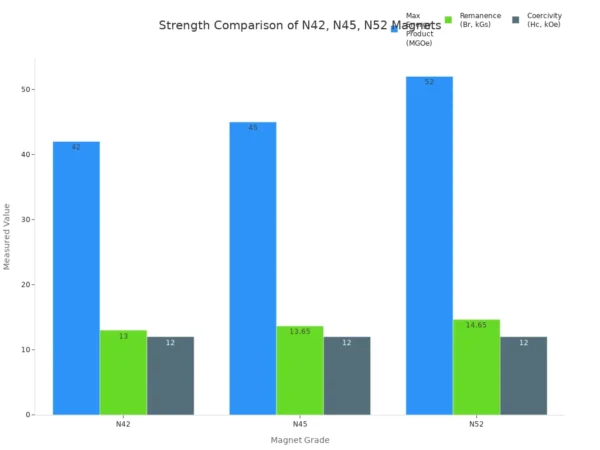

Micro magnets have a dramatically higher defective rate during production. Sometimes, we have to produce 800 – 2,000 pieces in order to obtain 50 qualified magnets. Their raw material is N52, N54, or N55, which are expensive.

Most of the defective magnets usually occur when workers are setting up and finetuning the machine. Micro neodymium magnets are too small and brittle. Even if the processing force is slightly higher, the magnets will be defective or even damaged.

Special Instruments

Production facilities for regular magnets cannot be used for micro magnets. Their tolerance will be more than acceptable. So, we need to use some special instruments. And we also have a Quadratic element measure to check the dimensions and make sure the product reaches the customer’s requirements.

Excellent Skilled Workers

Many procedures for producing micro magnets are actually manual work. Automatic machines have made great progress, but they still cannot produce some precision custom magnets. Human workers are still more flexible to suit the needs of precision work.

With our continuous efforts, Osenc has been expanding our capacities to deliver a wider range of micron magnets, and now we can process 0.2 mm magnets.

Osenc always provides long-term-stability products, which have high quality. We have achieved great development in this field.

Our products, especially our deep-hole thin magnetic rings are widely used in watches, clocks, micro-motor, meters, optical communication, and other fields.

Also, we can make a new design according to the customer’s drawing and request. Lots of customers are satisfied with our best techniques in magnetic tubes, magnetic cylinders, columnar magnets, magnetic pipe, hole magnets, magnetic ducts, pipe magnets, tube magnets, Cylinder magnets, deep hole magnets, etc.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.