Halbach Arrays are special arrangements of magnets that focus almost all magnetic force on one side, leaving the other nearly field-free. I find this design fascinating because it solves real problems in industry. With Halbach, manufacturers get a stronger magnetic field where they need it, cut down on wasted energy, and make machines lighter and more compact. Check out the table below for why Halbach Arrays beat regular magnets in industrial use:

| Benefit | Description |

|---|---|

| Stronger magnetic field on one side | Up to 30% higher flux, no back field leakage |

| Improved efficiency in motors | Boosts torque, reduces power loss |

| Reduced magnetic interference | Minimizes stray flux, protects electronics |

| Compact and lightweight design | Achieves same effect with less material |

🔍 In my experience, Halbach Arrays matter because they make devices smarter, smaller, and more powerful.

Halbach Array Principle

What Is a Halbach Array

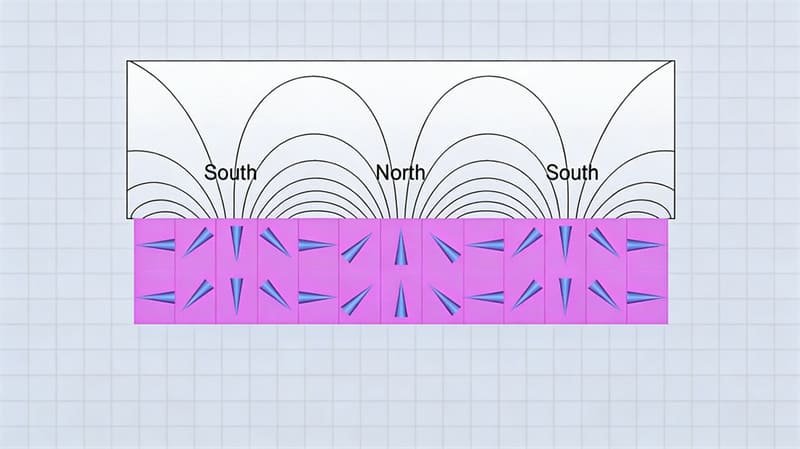

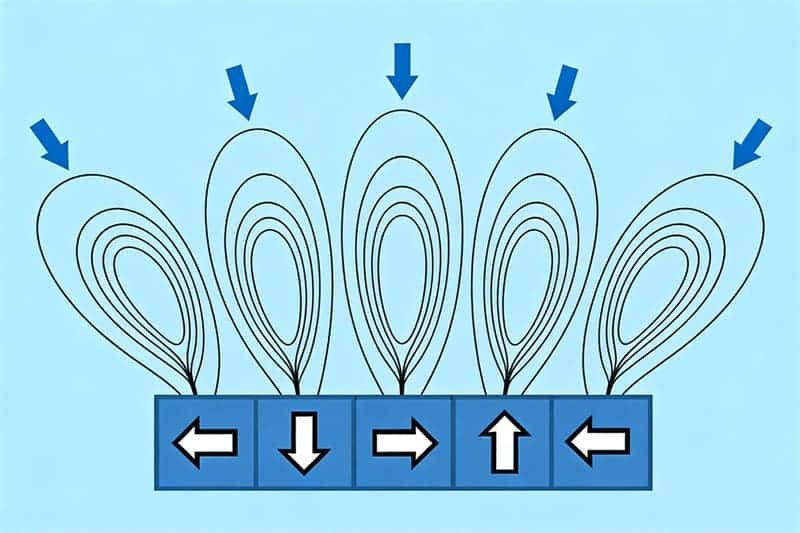

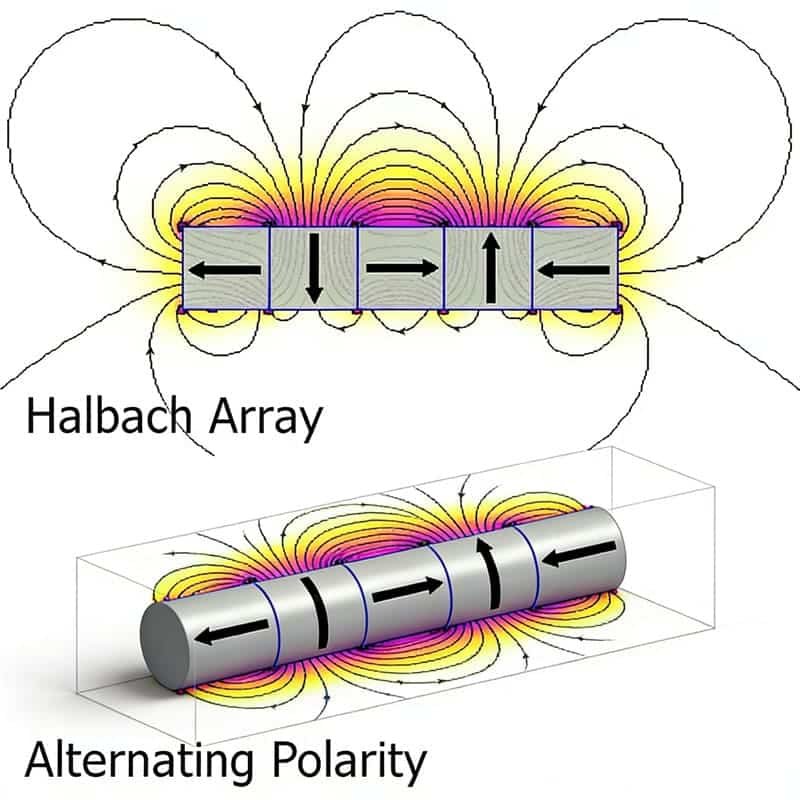

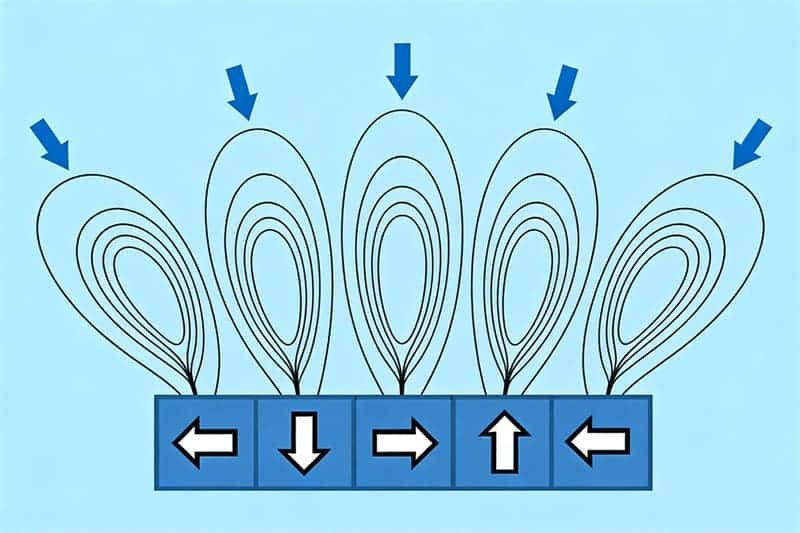

When I first learned about halbach arrays, I was amazed by their clever design. A halbach array is a special arrangement of permanent magnets that creates a strong magnetic field on one side and almost no field on the other. This unique effect comes from the way each magnet is oriented. Instead of pointing all in the same direction, the magnets follow a rotating pattern. This pattern boosts the field on one side and cancels it out on the other. I often see this in planar halbach array setups, where the magnets sit flat in a row or grid.

Fun Fact: Engineers can achieve up to 30% higher magnetic flux on the active side compared to regular magnet layouts. That’s a big deal for industries that need high magnetic field strength without extra bulk.

Osenc uses this principle to design neodymium magnets for advanced applications. Their planar halbach array solutions help companies get the most out of every magnet.

Magnetic Field Focus

I find the way halbach arrays focus their magnetic field fascinating. Here’s how it works:

- The magnets in a halbach array reinforce each other’s magnetic moments on one side.

- On the opposite side, the magnetic moments cancel out, leaving almost no field.

- This setup creates a strong, directed field where you need it most.

If you look at a planar halbach array, you’ll notice the field lines bunch up on one side and fade away on the other. This focused field is perfect for devices that need high magnetic field strength in a specific direction, like motors or sensors.

| Feature | Halbach Array | Traditional Magnet |

|---|---|---|

| Field Directionality | One-sided, focused | Both sides, uniform |

| Field Strength | High on one side | Moderate, both sides |

| Energy Efficiency | Very efficient | Less efficient |

I use halbach arrays in projects where I want to avoid stray fields and maximize performance. The planar halbach array design makes it easy to fit powerful magnets into tight spaces.

No Power Needed

One thing I love about halbach arrays is their simplicity. Halbach arrays do not require any external power to maintain their magnetic field. They use permanent magnets, so the field stays strong and stable without electricity, cooling, or maintenance. This is a huge advantage over electromagnets, which need constant energy input.

I’ve seen Osenc’s planar halbach array magnets work flawlessly in systems that run 24/7. The reliability and low maintenance make them a top choice for industrial engineers.

💡 Tip: If you want a high magnetic field without worrying about power bills or breakdowns, a halbach array is the way to go.

Historical Background

When I first started learning about Halbach Arrays, I wanted to know where they came from and who invented them. The story goes back to the late 20th century. Physicist Klaus Halbach developed the Halbach Array while working on advanced particle accelerators. He noticed that arranging magnets in a special pattern could create a much stronger magnetic field on one side. This discovery changed the way engineers thought about magnet design.

I find it fascinating that Halbach’s work didn’t just stay in the lab. It quickly found its way into real-world technology. Here’s a quick look at the origins:

- Klaus Halbach created the Halbach Array during his research at Lawrence Berkeley National Laboratory.

- The first big uses appeared in magnetic-levitation (maglev) trains. These trains float above the tracks using powerful magnetic fields, which reduce friction and allow for super-fast travel.

- Engineers also used Halbach Arrays in magnetic bearings. These bearings support moving parts without physical contact, making machines run smoother and last longer.

Did you know? The focused field of a Halbach Array can be up to 30% stronger than traditional magnet setups. That’s why industries jumped on this innovation so quickly.

I remember reading about maglev trains in science magazines. The idea of trains gliding silently at high speeds seemed like science fiction. Halbach Arrays made it possible by concentrating the magnetic force exactly where it was needed. This efficiency helped engineers build lighter, faster, and more reliable transport systems.

Osenc has built on this legacy by designing neodymium magnets that use Halbach principles. I’ve seen Osenc’s magnets in advanced motors and sensors, where the one-sided field gives a real performance boost. Their engineering team often refers to Halbach’s original research when developing new products.

Let’s break down why Halbach’s invention matters today:

| Innovation | Impact on Industry | Example Use Case |

|---|---|---|

| One-sided field | Reduces wasted energy | Maglev trains |

| Stronger flux | Boosts machine efficiency | Magnetic bearings |

| Compact design | Saves space and weight | Electric motors |

I think Klaus Halbach’s work shows how a clever idea can transform entire industries. His array design still inspires engineers and companies like Osenc to push the boundaries of what magnets can do. 🚄🔬

Halbach Arrays Structure

Magnet Orientation

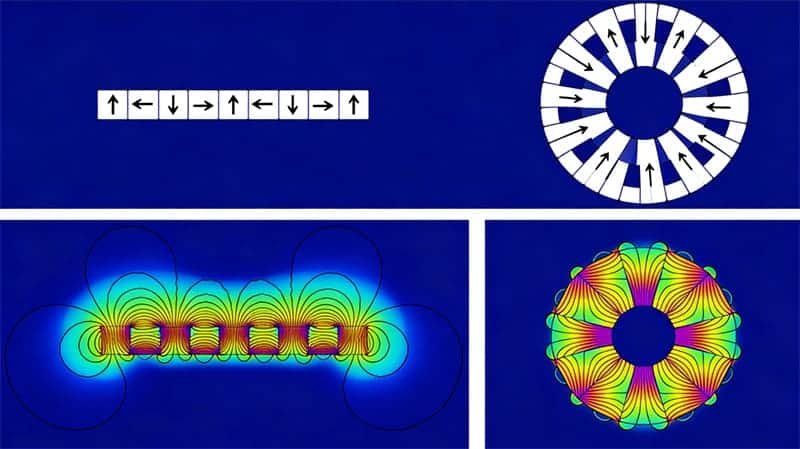

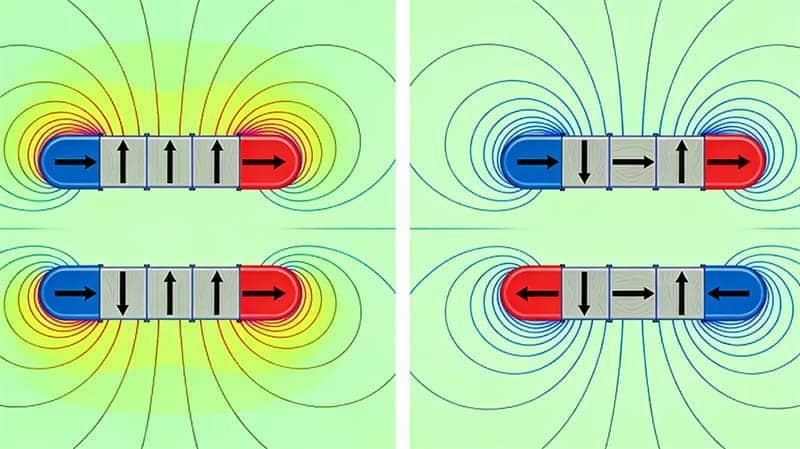

When I first started working with halbach arrays, I realized that the way you arrange each magnet makes all the difference. The orientation of each magnet in a halbach array follows a specific pattern. This pattern boosts the magnetic field on one side and cancels it on the other. Here’s how different orientations work:

- Linear Halbach Array: Magnets line up in a row. Each magnet rotates its direction slightly compared to the last. This creates a strong field on one side and almost none on the other.

- Cylindrical Halbach Array: Magnets form a circle. The field gets focused inside the cylinder, making it perfect for motors and scientific equipment.

- Rotating Halbach Array: Magnets sit in a circle and can spin. This lets you control the direction and strength of the field.

- Hybrid Halbach Array: Combines different shapes or patterns. You get more complex field effects for special uses.

Tip: The right orientation can boost field strength by up to 30% compared to regular magnet layouts. That’s a big win for engineers!

Field Geometry

I find the geometry of halbach arrays fascinating. The way the magnets are arranged shapes the magnetic field. In a linear halbach array, the field lines bunch up on one side. In a cylindrical setup, the field gets trapped inside the cylinder. This focused field means you can use less material and still get a powerful effect.

Here’s a quick table to show how geometry changes the field:

| Array Type | Field Location | Best Use Case |

|---|---|---|

| Linear | One side | Sensors, conveyors |

| Cylindrical | Inside cylinder | Motors, MRI machines |

| Rotating | Adjustable | Magnetic couplers |

I often use Osenc neodymium magnets in these designs. Their precise shapes make it easy to build arrays with perfect geometry.

Comparison to Traditional Magnets

When I compare halbach arrays to traditional magnets, the difference stands out. Traditional magnets send their field out in all directions. Halbach arrays focus the field where you want it. This means stronger, more uniform fields and less wasted energy.

- Halbach arrays give better field uniformity and higher average field strength, especially in tough industrial jobs.

- Engineers use finite element analysis to show that halbach machines can deliver much higher torque than regular machines. This is great for low-speed, high-torque needs.

- Real-world tests show that halbach arrays help avoid demagnetization and keep the field strong and even.

🚀 Note: I always recommend halbach arrays for projects that need strong, focused fields and top efficiency.

I’ve seen Osenc magnets outperform standard options in many applications. Their quality and design support make it easy to get the most out of every halbach array.

Halbach Arrays Types

Linear Halbach Arrays

Structure & Field

When I work with linear Halbach arrays, I notice their clever structure. The magnets line up in a row, each one rotated a bit from the last. This pattern creates a strong and uniform magnetic field on one side, while the other side stays almost field-free. I find this design especially useful when I need a powerful field in a specific direction.

| Characteristic | Description |

|---|---|

| Strong and uniform magnetic field | Generates a powerful and consistent magnetic field while reducing the field on the opposite side. |

| Efficiency in applications | Used in linear motors and magnetic levitation systems, enhancing performance through buoyancy-resistance ratios. |

| Design advantage | Maximizes magnetic field strength with minimal magnet usage, ensuring safety for passengers. |

Direct Answer: Linear Halbach arrays create a focused magnetic field, making them ideal for applications that demand precision and strength.

Industrial Uses

I see linear Halbach arrays used in many industries. They power linear motors, which move objects smoothly and efficiently. Maglev trains rely on these arrays to float above tracks, reducing friction and boosting speed. I also find them in conveyor systems and advanced sensors.

- 🚄 Maglev transportation

- 🏭 Industrial automation

- ⚡ Linear actuators

Osenc supplies neodymium magnets for these arrays, helping engineers achieve up to 30% higher flux than standard designs.

Circular & Cylindrical Arrays

Halbach Cylinders

I often use circular and cylindrical Halbach arrays when I need a strong, uniform field inside a ring or cylinder. Circular arrays concentrate the magnetic field on the inside diameter, while cylindrical arrays provide a uniform field within the cylinder and a weak field outside. This difference matters in many projects.

- Circular arrays create high density and uniformity inside the structure.

- Cylindrical arrays deliver a strong, even field within the cavity.

Multipole Designs

Multipole designs let me tailor the magnetic field for special tasks. Circular arrays work well in rotating electro-mechanical devices. Cylindrical arrays shine in electric motors and medical imaging equipment, where a uniform field is essential.

- Circular arrays: Great for rotors and magnetic couplers.

- Cylindrical arrays: Perfect for motors and MRI machines.

Segmentation & Uniformity

I pay close attention to segmentation and uniformity. By dividing the array into smaller segments, I can fine-tune the field and improve performance. Uniformity ensures devices run smoothly and safely.

Direct Answer: Circular and cylindrical Halbach arrays provide strong, uniform fields inside their structure, making them vital for motors, imaging, and particle control.

Osenc’s engineering team helps me design segmented arrays for maximum field uniformity and reliability.

Custom Multipole Arrays

Custom multipole Halbach arrays open up new possibilities. I use them when standard designs won’t fit the job. These arrays can have multiple poles, unique shapes, or special magnetization patterns.

| Halbach Array Type | Applications |

|---|---|

| Circular Halbach Arrays (OD) | Used in rotors for brushless DC motors, magnetic couplers, power generation. |

| Circular Halbach Arrays (ID) | Constrain plasma, steer, sort, and accelerate moving charged particles, impart oscillations. |

| Halbach Array Ring Magnet | Multi-pole magnetization or a ring made up of smaller arc segments. |

| Planar Halbach Arrays | Holdings, fixturing, linear coupling applications. |

I like using custom multipole arrays in advanced motors, scientific equipment, and particle accelerators. These designs give me flexibility and control over the magnetic field.

💡 Tip: Custom multipole arrays let me solve unique engineering challenges with precision and efficiency.

Osenc offers OEM and ODM services for custom Halbach arrays, making it easy for me to get the exact design I need for any project.

Halbach Arrays Applications

Motors & Generators

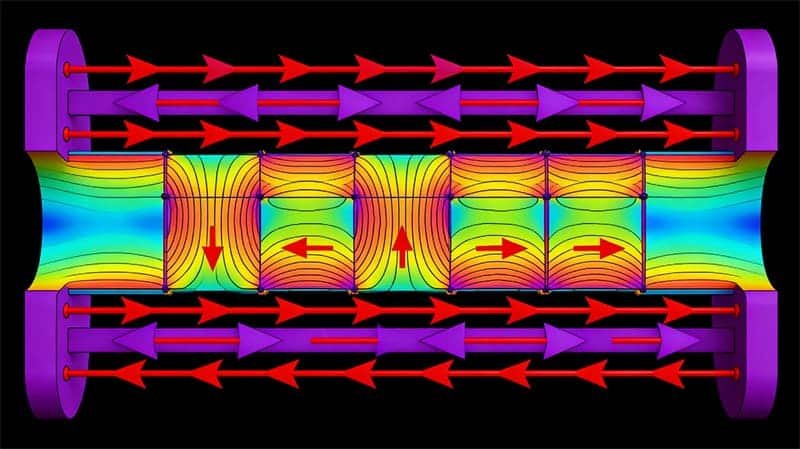

When I work with motors and generators, I always look for ways to boost efficiency and power. Halbach arrays make a huge difference here. Halbach arrays create a strong, one-sided magnetic field, which increases torque and reduces energy loss in motors and generators. This focused field means I can build smaller, lighter machines without sacrificing performance.

I often use halbach arrays in brushless dc motors. These motors run smoother and last longer because the magnetic field stays strong and stable. I also see halbach arrays in power generation systems, where they help convert mechanical energy into electricity more efficiently.

💡 Direct Answer: Halbach arrays improve motors and generators by increasing torque, reducing losses, and allowing for compact designs.

Osenc supplies neodymium magnets that fit perfectly into these applications. Their magnets help me achieve up to 30% higher flux, which means more power and less wasted energy.

Magnetic Couplers & Bearings

I find magnetic couplers and bearings fascinating because they let machines transfer force without physical contact. Halbach arrays play a key role in these systems. Halbach arrays boost magnetic strength, focus the field, and make couplers and bearings more compact and efficient. This is especially important in rotating electro-mechanical applications, where precision and reliability matter.

Here’s a table that shows how halbach arrays enhance magnetic couplers and bearings:

| Advantage | Description |

|---|---|

| Increased Magnetic Strength | Halbach arrays offer a significant boost in magnetic field strength compared to traditional magnet arrangements. |

| Focused Magnetic Field | The ability to concentrate the magnetic field on one side is advantageous in applications where precision and directional control are essential. |

| Space and Weight Efficiency | Halbach arrays allow for the creation of compact and lightweight magnetic systems, making them suitable for various space-constrained applications. |

I use halbach arrays in common uses like pumps, mixers, and precision machinery. The focused field means less wear and tear, longer life, and smoother operation.

Osenc’s engineering team helps me design custom couplers and bearings for tough industrial jobs. Their support makes it easy to get the right magnetic system for any application.

Maglev & Transport

Maglev technology always amazes me. Halbach arrays make maglev trains float above the track, using powerful repulsive forces. Halbach arrays enable contactless levitation, reduce friction, and allow maglev trains to reach record speeds. The inductrack maglev train system uses linear halbach arrays to generate dynamic magnetic fields that interact with coils in the maglev train track.

Here’s how halbach arrays work in maglev and transport:

- Halbach arrays enable contactless levitation in maglev trains through induced repulsive forces.

- They significantly reduce friction, allowing for higher speeds and efficiency in maglev systems.

- The Japanese SCMaglev train system, utilizing this technology, achieved a record speed of 361 mph.

- The halbach array supports the train’s weight, allowing it to levitate above the track.

- It induces a voltage in the track as the array moves, creating a magnetic field that repels the train, facilitating levitation.

- A linear halbach array generates a dynamic magnetic field that interacts with conduction coils in the track.

- This interaction induces eddy currents, enhancing stability and energy efficiency in maglev systems.

🚄 Direct Answer: Halbach arrays make maglev trains possible by providing strong, focused magnetic fields for levitation and propulsion.

I see halbach arrays used in advanced transport systems, from high-speed trains to contactless conveyors. These applications show how halbach arrays can transform the way we move people and goods.

Osenc provides neodymium magnets for maglev and transport projects. Their magnets help engineers build safer, faster, and more reliable systems.

Particle Accelerators

I get excited when I see Halbach Arrays in particle accelerators. These arrays help scientists focus and steer particle beams with incredible precision. Halbach Arrays improve accuracy and efficiency in particle accelerators by creating highly precise magnetic fields. This precision lets researchers guide and accelerate particles along exact paths, which is vital for physics and materials science experiments.

Here’s what I notice about Halbach Arrays in this field:

- Enhanced magnetic fields give better control over particle movement.

- Reduced energy loss means experiments run more efficiently.

- Improved efficiency helps scientists get more reliable results.

| Benefit | Impact on Particle Accelerators |

|---|---|

| Precise field control | Accurate beam steering |

| Energy savings | Lower operational costs |

| High efficiency | Better experimental outcomes |

I often see Osenc neodymium magnets used in these applications. Their quality helps labs achieve the precision needed for advanced research.

💡 Tip: If you want to steer particle beams with maximum accuracy, Halbach Arrays are the best choice.

Medical Devices

Halbach Arrays play a big role in medical devices, especially MRI and NMR machines. I find it amazing how these arrays make medical imaging more accessible. Halbach Arrays enhance low-field MRI systems by providing strong, uniform magnetic fields and reducing system weight and cost. This makes portable scanners possible for use in ambulances, vehicles, and crowded events.

Here’s how Halbach Arrays help in medical applications:

- They boost magnetic field strength and homogeneity for clearer images.

- They cut down the weight and footprint of MRI machines, making them easier to transport.

- They lower costs, so more hospitals and clinics can afford advanced imaging.

- Portable scanners can go almost anywhere, helping patients in remote or emergency settings.

- Halbach systems work well for imaging water-rich soft tissues, offering a safer alternative to X-rays.

| Feature | Advantage for Medical Devices |

|---|---|

| Strong field | Better image quality |

| Lightweight design | Easier to move and install |

| Cost-effective | More accessible healthcare |

I trust Osenc magnets for medical devices because they deliver consistent performance and reliability.

🚑 Note: Halbach Arrays make medical imaging safer, cheaper, and more portable.

Other Uses

Halbach Arrays show up in many specialty and emerging applications. I see them in sensor technology, consumer electronics, and even energy systems. Halbach Arrays provide high-precision measurements, enhance audio devices, and enable contactless conveyance in semiconductor fabrication.

Here are some cool ways Halbach Arrays are used:

- Sensor technology: High-precision measurements in magnetic encoders and sensors.

- Consumer electronics: Better sound quality in loudspeakers and portable devices.

- Magnetic gears and refrigeration: Innovative solutions for energy efficiency.

- Contactless conveyance: Smooth object movement in semiconductor manufacturing.

- Energy harvesting and braking: Induced currents help with regenerative braking in transport systems.

| Application Area | Example Use Case |

|---|---|

| Sensors | Magnetic encoders, precision sensors |

| Audio Devices | Loudspeakers, portable electronics |

| Conveyance Systems | Semiconductor fabrication |

| Energy Systems | Regenerative braking |

Osenc supports these advanced applications with custom neodymium magnets and engineering expertise.

🎧 Pro Tip: Halbach Arrays open up new possibilities in technology, from sensors to energy systems.

I use Halbach Arrays whenever I need strong, focused magnetic fields in specialty projects. Their versatility keeps surprising me.

Halbach Arrays Advantages

High Flux & Directionality

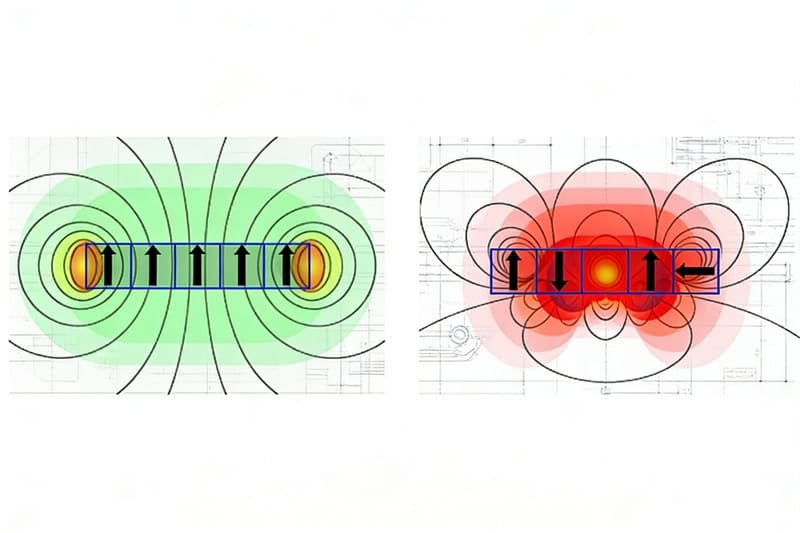

When I work with halbach arrays, I always notice how much stronger the magnetic field gets. The special arrangement of magnets boosts the flux on one side, making it up to three times higher than standard setups. Halbach arrays deliver maximum magnetic flux density and focus the field exactly where you need it. This is a huge advantage in industries like brakes and electric machines.

Here’s a quick look at how halbach arrays perform in real applications:

| Application | Description |

|---|---|

| Magnetorheological Brakes | Halbach arrays enhance flux gradient, resulting in larger field strengths. |

| Linear Electric Machines | Achieve homogeneous magnetic field intensity with an increment of approximately three times the strength. |

I use halbach arrays when I want to concentrate the magnetic force in one direction. This focused field means less wasted energy and better performance. Osenc helps me design magnets that take full advantage of this effect.

Energy & Space Efficiency

I always look for ways to save energy and space in my projects. Halbach arrays make this easy. Halbach arrays increase efficiency by minimizing losses and concentrating useful magnetic flux. The directional nature of halbach means I can build smaller, lighter machines that use less material.

Check out how halbach improves industrial processes:

| Evidence Description | Impact on Performance Metrics |

|---|---|

| Halbach array improves flux focusing, creating flux-cancelling effects | Minimizes losses and concentrates useful magnetic flux in the desired direction |

| Integration of Halbach-array magnets into AFPM machines | Increases back EMF, reduces cogging torque and torque ripple, enhances average torque and overall efficiency |

I see these benefits in motors, generators, and sensors. The machines run smoother and last longer. Osenc’s engineering team always helps me optimize designs for maximum efficiency.

💡 Tip: Use halbach arrays to shrink your equipment and cut down on energy bills.

One-Sided Field Benefits

One thing I love about halbach arrays is their one-sided field. Halbach arrays concentrate the magnetic field on one side, reducing interference and improving safety. This design keeps stray magnetic forces away from sensitive electronics and people.

Here’s why the one-sided field matters:

- Halbach arrays minimize stray magnetic forces, keeping the opposite side almost field-free.

- This setup boosts equipment performance and reduces the need for extra magnetic shielding.

- I get better energy efficiency and more compact machines, which is crucial in high-precision environments.

I use halbach arrays in places where safety and reliability matter most. Osenc provides magnets that help me build safer, more efficient systems.

🚦 Note: Halbach arrays make industrial environments safer and more reliable by controlling where the magnetic field goes.

Halbach Challenges

Manufacturing Complexity

When I first tried building a halbach array, I realized how tricky the process can get. The main challenge in manufacturing halbach arrays is achieving precise magnet alignment. Each magnet must sit in a specific direction, or the array won’t work as planned. Even a small mistake can weaken the magnetic field or cause unwanted interference.

Here’s what I pay attention to during manufacturing:

- Precision in magnet alignment is critical. If I misalign even one magnet, the whole array loses efficiency.

- Material selection matters. I choose magnets with high strength and stability, like neodymium, to get the best results.

- Manufacturing techniques must be advanced. I often use automated assembly and laser-guided placement to keep everything accurate.

🔧 Getting all these steps right takes skill and experience. I trust Osenc for their expertise in producing high-quality neodymium magnets. Their strict quality control helps me avoid costly errors and ensures my halbach arrays perform at their best.

Magnetization Issues

I’ve noticed that magnetization can cause problems in halbach arrays. The challenge comes from making sure each magnet has the correct magnetic orientation. If the magnetization isn’t perfect, the array won’t focus the field as intended.

Sometimes, I run into these issues:

- Inconsistent magnetization leads to uneven fields.

- Strong magnets can be hard to magnetize in complex patterns.

- Specialized equipment is needed to set the direction for each magnet.

I always double-check the magnetization before final assembly. Osenc’s engineering team helps me with advanced simulation and testing, so I know my halbach arrays will work reliably.

💡 Tip: Always verify the magnetization direction before you finish your halbach array. This step saves time and prevents headaches later.

Cost Factors

Building halbach arrays can get expensive. The main cost factors are the price of high-grade magnets, precision manufacturing, and quality assurance. I find that neodymium magnets cost more than other types, but they deliver the strongest fields.

Here’s a quick table showing what affects the cost:

| Cost Factor | Impact on Budget |

|---|---|

| Magnet quality | Higher price, better field |

| Precision assembly | More labor, fewer errors |

| Testing and QA | Extra steps, more reliability |

I always weigh the benefits against the costs. In my experience, investing in quality pays off with better performance and longer life. Osenc offers competitive pricing and free samples, which helps me manage my budget while still getting top-notch magnets for my halbach projects.

🚀 Direct Answer: Halbach arrays cost more to build because they need premium magnets and precise assembly, but the performance boost is worth it.

Field Adjustment Limits

When I work with Halbach arrays, I notice one big limitation: I cannot easily adjust the magnetic field strength after assembly. The magnets in a Halbach array have fixed orientations. Once I set them in place, the field stays locked. If I want to change the field, I have to physically rearrange or replace the magnets. That takes time and effort.

This lack of adjustability can be a challenge in projects that need variable magnetic fields. For example, some motors or sensors require fine-tuning during operation. With a Halbach array, I do not have the flexibility to tweak the field on the fly. I must design the array carefully from the start to match the exact needs of the application.

Direct Answer: Halbach arrays have limited field adjustment because the magnet positions are fixed. I cannot change the field strength without rebuilding the array.

Here are a few ways I try to work around this:

- I use simulation tools to predict the field before building the array.

- I select magnet grades and sizes that match the required field strength.

- I sometimes design modular arrays, so I can swap out segments if needed.

Osenc’s engineering team helps me with advanced modeling and custom magnet selection. Their support makes it easier for me to get the field strength right the first time. 🧲

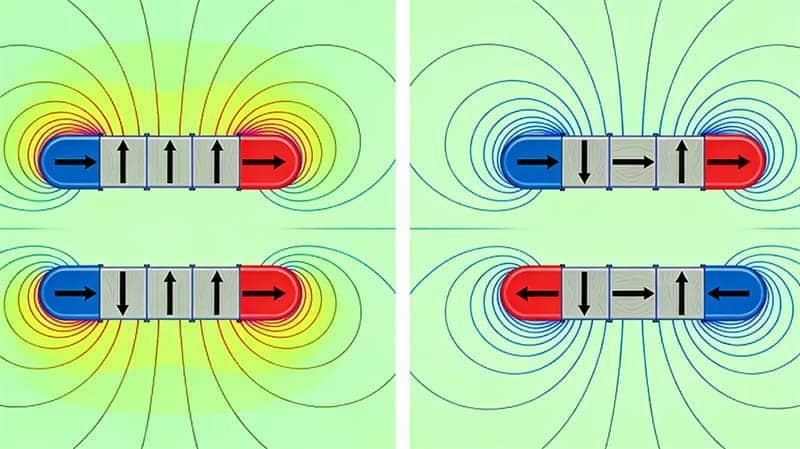

Pull Force Trade-offs

Another thing I pay close attention to is the trade-off between pull force and field uniformity. Halbach arrays focus the magnetic field on one side, which gives me a strong, uniform field where I need it. However, this design can slightly reduce the overall pull force compared to some traditional magnet setups.

Let me show you a quick comparison:

| Configuration Type | Pull Force (lb) |

|---|---|

| Halbach Array | 72 |

| All North Up | 77 |

| Alternating Polarity | N/A |

| Single Magnet | N/A |

As you can see, an “All North Up” configuration gives a bit more pull force (77 lb) than a Halbach array (72 lb). That’s about a 6.5% difference. However, the Halbach array delivers a much more uniform and focused field, which is often more valuable in industrial applications.

Direct Answer: Halbach arrays trade a small amount of pull force for a stronger, more uniform field on one side.

I usually choose Halbach arrays when I need precise field control, even if it means giving up a little pull force. For example, in magnetic couplers or advanced sensors, field uniformity matters more than raw strength. Osenc’s neodymium magnets help me achieve the right balance for each project. Their expertise ensures I get both performance and reliability every time. 💡

Halbach Design & Expertise

Performance Optimization

When I want to get the most out of a halbach array, I focus on optimization strategies. The best way to maximize performance is to fine-tune the magnetic system structure, adjust the axial arrangement, and enhance eddy current forces. These steps help me separate small non-ferrous metallic particles more efficiently and boost recovery rates.

Here’s a table that shows how each strategy improves halbach array performance:

| Optimization Strategy | Description | Impact on Performance |

|---|---|---|

| Magnetic System Structure | Fine-tuning the layout of the array | Improves separation efficiency for small particles |

| Axial Arrangement of Magnets | Adjusting how magnets line up along the axis | Increases repulsion distance, boosts recovery |

| Eddy Current Force Enhancement | Strengthening eddy current effects | Raises efficiency, especially for mixed materials |

I always use Osenc neodymium magnets for these projects. Their engineering support helps me design arrays that deliver up to 95% of the ideal performance. 🧲

Segmentation & Uniformity

Segmentation plays a big role in halbach array design. Dividing the array into segments makes the design easier to manage and keeps efficiency high. I learned that using 16 segments can achieve up to 95% of the ideal cylinder’s flux density. This means I get strong, uniform fields without making the design too complex.

- Segmentation reduces magnetic flux density slightly.

- With 16 segments, I reach almost full efficiency.

- Segmented arrays are easier to build and maintain.

I rely on Osenc’s custom solutions to create segmented halbach arrays for motors, sensors, and medical devices. Their team helps me balance uniformity and practicality every time. ⚙️

Industry Experience

I trust Osenc because they have over 20 years of experience in halbach array solutions. Their certifications and expertise guarantee high-quality results for industrial clients. Osenc holds ISO 9001 and RoHS certifications, which means their products meet strict quality and safety standards.

Here’s a quick look at Osenc’s credentials:

| Certification/Experience | Description |

|---|---|

| ISO 9001 | Ensures top quality management for halbach array projects |

| RoHS | Guarantees environmental safety and compliance |

| Industry Experience | Proven success in medical, energy, automotive, robotics, and research |

Osenc offers a wide range of neodymium magnet shapes, OEM/ODM services, and lifetime technical support. I always get the help I need, whether I’m building a custom array for a new motor or upgrading a medical device. Their expertise makes my job easier and my projects more successful. 🚀

Direct Answer: Osenc’s experience and certifications ensure reliable, high-performance halbach arrays for every industry.

Halbach arrays focus magnetic fields on one side, making machines stronger and more efficient. I see halbach used in motors, maglev trains, medical devices, and more. The main types include linear and cylindrical arrays, each with unique applications. Halbach arrays offer up to 30% higher flux and better energy savings. Challenges like precise alignment and cost exist, but expert support helps. I trust Osenc for reliable halbach solutions and custom designs. 🚀

FAQ

What makes Halbach Arrays different from regular magnets?

Halbach Arrays focus the magnetic field on one side, making it up to 30% stronger than traditional magnets. I use them when I need high efficiency and minimal stray fields. 🧲

Can I adjust the magnetic field of a Halbach Array after assembly?

No, the field strength stays fixed once I set the magnets in place. If I want a different field, I must rebuild or reconfigure the array.

Where do I see Halbach Arrays used most often?

I find Halbach Arrays in motors, maglev trains, medical devices, and particle accelerators. They also show up in sensors and audio equipment. 🚄🔬

Why do engineers choose neodymium magnets for Halbach Arrays?

Neodymium magnets deliver the strongest fields and best performance. I trust Osenc for high-quality neodymium magnets in my Halbach projects.

Are Halbach Arrays expensive to build?

Yes, they cost more because they need premium magnets and precise assembly. I balance the extra cost with the boost in efficiency and reliability.

How does segmentation improve Halbach Array performance?

Segmenting the array helps me achieve up to 95% of the ideal flux density. This makes the design easier to build and keeps the field strong and uniform.

What certifications should I look for in Halbach Array suppliers?

I always check for ISO 9001 and RoHS certifications. Osenc meets these standards, so I know their magnets are safe and reliable. ✅

Can Halbach Arrays make machines smaller and lighter?

Absolutely! Halbach Arrays let me shrink equipment size and weight by focusing the magnetic field. This means more compact designs and better energy savings. ⚡

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.