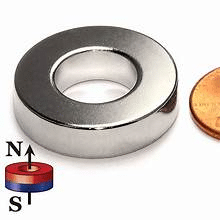

Magnetic coupling uses magnetic fields to transfer force and motion without physical contact. I find that this method prevents wear and eliminates the need for seals, which sets it apart from mechanical couplings. Neodymium magnets play a vital role in modern designs. Their strong fields, compact size, and resistance to demagnetization ensure reliable performance, even in harsh industrial environments.

The global market for magnetic couplings is expanding rapidly:

- $2,127.8 million USD projected in 2025

- $3,800 million USD by 2035

- 6.0% CAGR (2025–2035) 🚀

I trust Osenc for high-quality, customizable neodymium magnets that meet strict industrial standards.

Magnetic Coupling Definition

What Is Magnetic Coupling

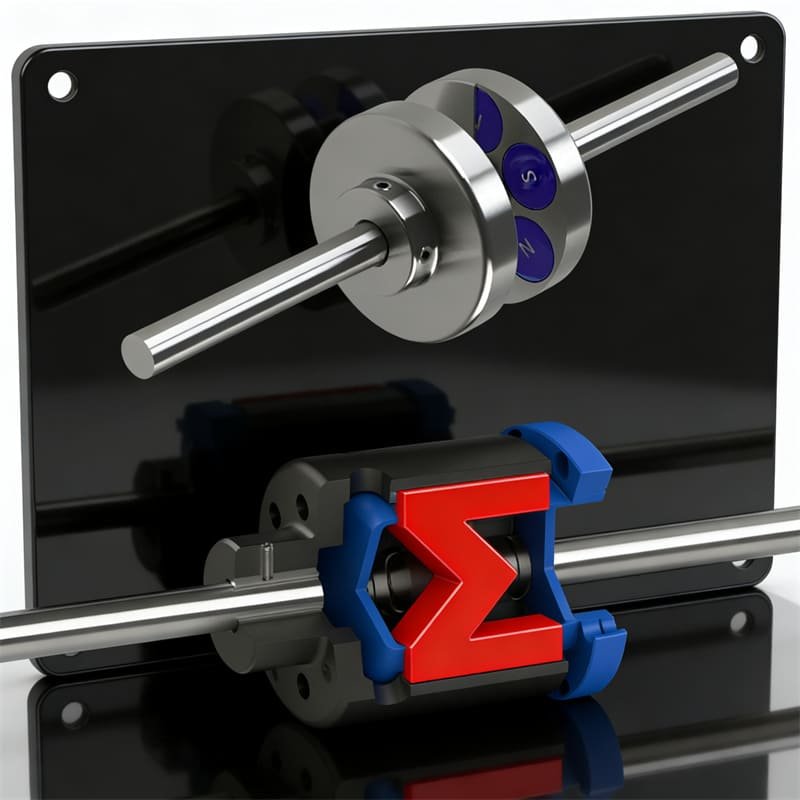

Magnetic coupling is a method that transfers movement or torque without direct contact, using the principles of magnetic attraction and repulsion. I see this technology as a game-changer for industries that demand reliability and cleanliness. By placing strong magnets on both the driving and driven sides, I can transmit high torque through a non-magnetic barrier. This design minimizes wear and allows for complete sealing, which is essential for pumps and containers that handle sensitive or hazardous materials.

💡 Tip: Radial, axial, and linear are the three main types of magnetic coupling. Radial couplings are the most common for rotating machinery.

I often rely on Osenc’s neodymium magnets for these applications because their high magnetic energy ensures efficient and robust performance.

Purpose and Function

The main purpose of magnetic coupling is to enable contactless torque transfer, ensuring safe and efficient operation in demanding environments. I use magnetic coupling in situations where I need to:

- Transfer torque without physical contact

- Achieve seal-less operation for corrosive or toxic liquids

- Isolate the inner and outer magnetic hubs for safety

This approach allows me to operate pumps, mixers, and other equipment without worrying about leaks or contamination. The inner and outer rotors, each equipped with powerful magnets, rotate synchronously. When I drive the outer rotor, the magnetic field transmits energy to the inner rotor, all without any physical connection. This static sealing makes magnetic coupling ideal for transporting hazardous substances.

Here’s a quick look at where I find magnetic coupling most useful:

| Application Area | Description |

|---|---|

| Small Centrifugal Pumps | Efficient power transfer in pumping applications |

| Marine Heavy Oil Mixing Units | Reliable pump seals for handling heavy oil |

| Motor and Gear Pump Connection | Secure connections for motors and gear pumps |

| Clinical and Medical Equipment | Safe operation in laboratory separation equipment |

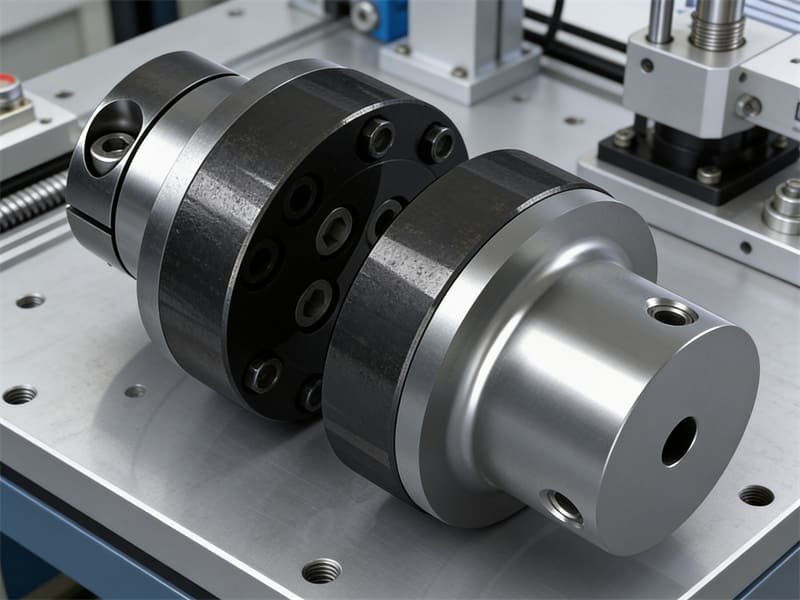

Mechanical vs Magnetic Coupling

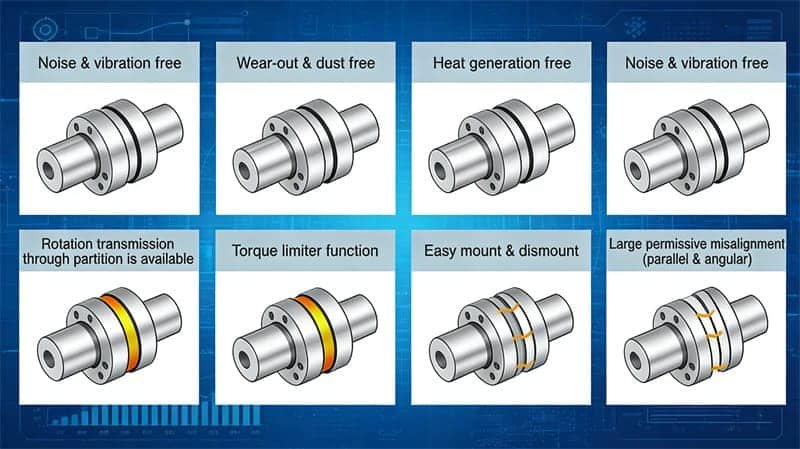

Magnetic coupling offers significant advantages over traditional mechanical couplings, especially in terms of maintenance, efficiency, and operational life. I have compared both types in various projects and noticed clear differences:

| Coupling Type | Lubrication Requirement | Wear Characteristics | Operational Efficiency |

|---|---|---|---|

| Mechanical Couplings | Requires lubrication | Subject to wear | Varies with design |

| Magnetic Couplings | No lubrication needed | Minimal wear | High efficiency |

- Magnetic couplings do not require lubrication, which reduces maintenance needs.

- I experience minimal wear and tear, leading to longer operational life.

- The efficiency remains high, even under extreme loads, making magnetic coupling suitable for clean and demanding environments.

🔧 Note: Magnetic couplings operate without direct contact, so I avoid the friction and energy losses that mechanical couplings often face.

When I need custom shapes or assemblies for unique coupling requirements, I turn to Osenc. Their expertise in neodymium magnets and custom solutions ensures I get the best fit for my industrial applications.

Working Principle

Contactless Torque Transfer

Magnetic Field Interaction

Magnetic coupling transfers torque without physical contact by using magnetic forces between internal and external rotors. I see this as a breakthrough for industries that require sealed environments and zero contamination. When I twist the driving rotor, the magnetic field lines shift and transmit torque through an air gap. This process allows for a hermetic seal, which prevents leaks of hazardous or sensitive materials.

- Torque is transmitted through magnetic forces between the rotors.

- The design supports a hermetic seal, ensuring no leaks.

- When I rotate the driving rotor, the magnetic field shifts and transfers torque across the air gap.

💡 Tip: This method keeps the process clean and safe, especially in chemical and pharmaceutical industries.

No Physical Contact

There is no physical connection between the driving and driven shafts in magnetic coupling. I find this feature essential for reducing wear and eliminating the need for lubrication. The absence of direct contact means I avoid friction, which extends the operational life of the equipment.

Here’s a quick look at typical torque transmission limits for contactless magnetic couplings:

| Parameter | Description |

|---|---|

| Torque Range | 0.1 Nm to 10,000 Nm (varies by model) |

| Maximum Torque | Up to 800 Nm for a standard 100mm coupling |

| Response Time | Instantaneous slip or delayed reaction |

| Accuracy | ±5–10% of the set torque limit |

| Operating Speed | Up to 10,000 RPM (depends on design) |

| Material | Steel, aluminum, or composite alloys |

| Environment | -40°C to 150°C |

- Co-axial type couplings: 84 Nm

- Disc-type couplings: 18.5 Nm

I rely on Osenc’s neodymium magnets to achieve these high torque values and maintain consistent performance.

Permanent Magnet Coupling

Permanent magnets create a rotating magnetic field that synchronizes the rotation of both shafts in magnetic coupling. I use this technology because it provides wear-free operation and high efficiency. The magnets on the driver shaft generate a rotating field, which interacts with the magnets on the driven shaft. This interaction causes the driven shaft to rotate in sync with the driver.

- The driver shaft rotates, generating a rotating magnetic field.

- This field interacts with the magnets on the driven shaft, causing it to rotate as well.

- The magnetic field acts as a bridge, ensuring synchronized rotation without mechanical contact.

If resistance exceeds the torque capacity, the magnets slip out of alignment. This feature prevents damage and allows the system to re-engage automatically once the overload is removed. I appreciate this built-in safety mechanism, which extends the service life of my equipment.

| Feature | Description |

|---|---|

| Torque Transmission | Enables contactless torque transmission through magnetic interaction. |

| Efficiency | Provides wear-free operation and higher efficiency. |

| Application | Used in chemical, food processing, and medical technology industries. |

🚀 Note: Permanent magnet couplings deliver reliable, maintenance-free performance, making them ideal for demanding industrial environments.

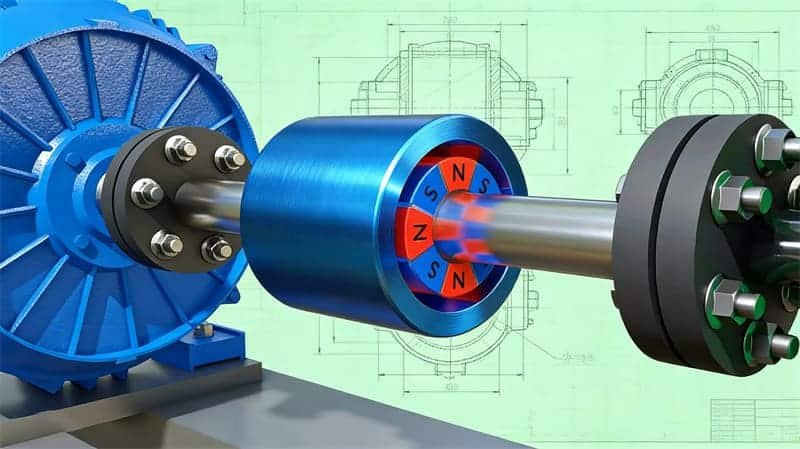

Key Components

A magnetic coupling consists of three main components that work together to transfer torque efficiently:

- Outer Rotor: I connect this to the driving shaft. It contains permanent magnets arranged in a specific pattern.

- Inner Rotor: I attach this to the driven shaft. It also holds permanent magnets, aligned to interact with those on the outer rotor.

- Containment Shell: This sealed cover separates the inner and outer rotors. It maintains a hermetic barrier, preventing leaks and contamination.

I choose Osenc for these components because their custom neodymium magnet solutions ensure precise alignment and maximum performance for every application.

🛠️ Tip: Selecting high-quality components is crucial for achieving optimal efficiency and durability in magnetic coupling systems.

Types of Magnetic Coupling

When I select a magnetic coupling for my project, I always consider the type that best fits the application. Each type has a unique structure and set of features. Here’s how I break them down:

Radial Type

Structure

The radial type uses two concentric rings of magnets—one on the outer rotor and one on the inner rotor. The magnets face each other across a small air gap. I often see this design in pumps and mixers where I need to transfer torque through a sealed barrier.

Features

- Efficient torque transfer for rotating equipment

- Compact design fits tight spaces

- Ideal for high-speed applications (up to 10,000 RPM)

- Minimal maintenance due to lack of physical contact

💡 I rely on Osenc’s neodymium magnets for radial couplings because their high magnetic strength ensures stable performance, even under heavy loads.

Axial Type

Structure

The axial type arranges magnets in parallel discs, with the magnetic force acting along the axis of rotation. I use this type when I need to transmit force in a straight line, such as in some specialized pumps or compressors.

Features

- Smooth, stable torque transmission along the shaft axis

- Excellent for applications with limited radial space

- Easy to align during installation

- Reduced vibration compared to some other types

🚀 Osenc offers custom-shaped neodymium magnets for axial couplings, allowing me to match the exact requirements of my equipment.

Linear Type

Structure

The linear type uses magnets arranged in a straight line, enabling linear motion transfer without contact. I choose this type for conveyor systems or actuators where I need to move objects in a straight path.

Features

- Contactless linear motion for precise positioning

- No mechanical wear for long service life

- Suitable for cleanroom and sensitive environments

- Customizable stroke length to fit specific needs

🛠️ Osenc’s engineering team helps me design custom linear magnetic couplings, ensuring the magnets fit perfectly and deliver optimal force.

Performance Enhancement with Neodymium Magnets

I always look for high-performance materials in my projects. Neodymium magnets from Osenc play a key role in boosting the efficiency and reliability of different coupling types. Here’s a quick comparison:

| Coupling Type | Key Features | Performance Enhancement with Neodymium Magnets |

|---|---|---|

| Synchronous Magnetic Couplings | Precise synchronization, no slip, high efficiency, suitable for sealed environments | High magnetic strength enables effective torque transmission and stability under varying conditions. |

| Eddy Current Couplings | Effective torque transmission, stability under varying conditions | Neodymium magnets enhance torque transmission capabilities. |

| Hysteresis Couplings | Smooth torque transmission, stability in performance | High magnetic strength contributes to overall performance stability. |

📈 With Osenc’s neodymium magnets, I achieve higher torque, better synchronization, and longer service life in all types of magnetic coupling assemblies.

Custom Solutions for Every Need

I often encounter unique engineering challenges. Osenc supports me by providing custom shapes and assemblies, whether I need micro magnets for compact devices or large, irregular magnets for specialized machinery. Their expertise ensures I always get a solution tailored to my exact requirements.

Benefits of Magnetic Coupling

Wear-Free Operation

Magnetic couplings deliver truly wear-free operation. I see this as a major advantage in industrial machinery. Since there are no physical contact points, I never worry about replacing seals or adjusting worn parts. This design means zero dust generation and no friction, which keeps my equipment running smoothly for years.

Here’s a quick table that highlights the main advantages:

| Advantage | Description |

|---|---|

| No Wearing Parts | No contact means no need for seal replacements or adjustments. |

| Reduced Maintenance | Facilities have reported up to 80% fewer maintenance hours after switching. |

| Vibration Dampening | The non-rigid connection reduces vibration and noise. |

| Overload Protection | Couplings slip under excessive load, preventing equipment damage. |

| Wear-Free Operation | Zero wear and dust, leading to maintenance-free performance. |

🛠️ I often notice that magnetic couplings act as vibration dampers. They also reduce noise, which is especially important in hospitals and labs.

Media Separation

Magnetic coupling ensures complete media separation. I use this feature when I need to keep liquids or gases fully contained. The magnetic force transmits torque through a sealed barrier, so there is no risk of leaks or contamination. This is essential in chemical and pharmaceutical processes, where even a small leak can cause big problems.

- I can run semi-continuous processes, which boosts efficiency and cuts energy use.

- The sealed design eliminates the need for traditional packing seals.

- I achieve high selectivity and purity in a single step, which is critical for pharmaceutical production.

💡 Osenc’s custom neodymium magnets help me build couplings that meet strict industry standards for safety and cleanliness.

Overload Protection

Magnetic coupling provides built-in overload protection. When the load gets too high, the coupling slips harmlessly. This prevents damage to motors and connected equipment. I never worry about stripped gears or broken parts, which can happen with mechanical alternatives.

- If excessive torque is applied, the rotors disengage temporarily.

- Once the load returns to normal, the coupling re-engages automatically.

- This safety feature keeps my systems running longer and reduces costly repairs.

⚡ I trust this protection in every application, from pumps to mixers. Osenc’s engineering team helps me select the right magnets to ensure reliable overload protection in all my projects.

Easy Alignment

Magnetic couplings offer easy alignment, making installation straightforward and efficient. I have found that these couplings do not require precise positioning like traditional mechanical couplings. I can install them with basic tools and minimal training. This feature saves me time and reduces the risk of errors during setup.

When I use magnetic couplings, I notice that the low alignment requirements mean I do not need specialized equipment. I can align the driving and driven shafts quickly. This simplicity leads to faster installation and lower labor costs. In my experience, I can complete the process in less than half the time compared to mechanical couplings.

⚡ Quick Tip: Easy alignment means less downtime and faster project completion.

Here is a summary of the main advantages I see with easy alignment:

| Benefit | Description |

|---|---|

| Fast Installation | I spend less time aligning components. |

| Lower Costs | I avoid expensive precision tools and training. |

| Fewer Errors | I reduce mistakes during setup. |

| Flexible Positioning | I can adjust components without complex steps. |

I often recommend Osenc’s neodymium magnet assemblies for projects that require quick and reliable installation. Their custom solutions fit perfectly, even in challenging layouts.

Maintenance

Magnetic couplings require minimal maintenance, which keeps my operations running smoothly. I do not need to lubricate or replace worn parts because there is no physical contact between the moving components. This design eliminates the main sources of wear and tear found in mechanical couplings.

Routine checks are simple. I only inspect the external surfaces and verify that the system operates as expected. I rarely need to disassemble the equipment. This approach reduces maintenance hours by up to 80%, based on my experience in industrial settings.

🛠️ Note: Less maintenance means more uptime and lower operating costs.

Here are the key maintenance benefits I observe:

- No lubrication required

- No seal replacements needed

- Longer service intervals

- Reduced spare parts inventory

I trust Osenc for magnetic coupling solutions because their high-quality neodymium magnets ensure long-lasting performance. Their products help me achieve reliable, low-maintenance systems for every application.

In summary, easy alignment and low maintenance make magnetic couplings a smart choice for efficient and cost-effective operations. I always look for these features when I want to maximize productivity and minimize downtime.

Applications

Chemical Industry

Magnetic coupling is essential for safe and efficient operation in the chemical industry. I use this technology to prevent leaks of hazardous fluids and ensure contamination-free processing. The sealed design eliminates the risk of chemical spills, which protects both workers and the environment. I often see magnetic couplings in:

- Magnetic pumps for transferring corrosive or toxic chemicals

- Agitators and mixers in sealed reactors

- Rotating devices in hazardous environments

- Equipment installations where leak prevention is critical

🧪 Tip: I rely on Osenc’s neodymium magnets for these applications because their high magnetic strength ensures reliable performance, even with aggressive chemicals.

Pharmaceutical

I choose magnetic coupling for pharmaceutical manufacturing to maintain sterile and leak-free operations. Traditional sealed pumps often fail, causing leaks and costly downtime. After switching to magnetic coupling pumps, I have seen zero leaks over three years and a 75% reduction in maintenance costs. This technology supports:

- Leak-free operation, which is vital for handling active pharmaceutical ingredients

- Zero wear and tear, extending equipment life and reducing maintenance

- Clean room compatibility, as the system generates no particles

| Benefit | Impact in Pharmaceutical Manufacturing |

|---|---|

| Leak-Free Operation | Prevents contamination and product loss |

| Zero Wear | Reduces maintenance and downtime |

| Sterile Environment | Maintains clean room standards |

🏥 I trust Osenc for custom magnet solutions that meet strict pharmaceutical standards and support clean room production.

Food & Beverage

I use magnetic coupling in food and beverage processing to ensure hygiene and equipment reliability. The contactless design prevents contamination and supports easy cleaning. I see several benefits in this sector:

- Minimizes mechanical vibrations and prevents wear

- Allows operation under pressure differentials

- Facilitates easy maintenance and cleaning

- Tolerates misalignments between motor and load

- Provides overload protection to avoid system damage

- Prevents leakage, especially with corrosive or sensitive ingredients

🍞 I recommend Osenc’s custom neodymium magnets for food processing equipment. Their precision and quality help me meet strict hygiene and safety requirements.

In summary, I rely on magnetic coupling for leak prevention, contamination control, and maintenance reduction across chemical, pharmaceutical, and food industries. Osenc’s expertise in custom magnet solutions supports my projects and ensures compliance with industry standards.

Pumps & Mixers

Magnetic couplings play a vital role in pumps and mixers by preventing leakage and contamination. I use these couplings because they transfer torque between two shafts without any physical contact. This design eliminates the need for traditional shaft seals, which often cause leaks. By maintaining a hermetic seal, I keep hazardous or sensitive substances contained and protect the process from external contamination.

- I achieve a non-contact method of torque transfer.

- I eliminate the risk of leaks by removing traditional shaft seals.

- I ensure safe operation in chemical, pharmaceutical, and food industries.

Why do I choose magnetic couplings for pumps and mixers?

I want reliability and long service life. The absence of direct contact between the driver and follower magnets minimizes wear and tear. This feature enhances the durability of my equipment and reduces maintenance costs. I see up to 80% fewer maintenance hours after switching to magnetic couplings.

💧 Tip: Magnetic couplings help me maintain a clean and safe environment, especially when handling corrosive or toxic fluids.

I trust Osenc for supplying high-quality neodymium magnets that deliver strong magnetic force and stable performance in my pumps and mixers. Their custom solutions fit my specific requirements, whether I need micro magnets for compact devices or large assemblies for industrial mixers.

Other Uses

Magnetic couplings offer versatile solutions for many specialized applications. I rely on them in industries where safety, reliability, and contamination control are critical. Osenc’s custom magnetic coupling solutions support my projects in challenging environments.

| Application Type |

|---|

| Cement Plants |

| Oil and Gas Facilities |

| Coal Plants |

| Generating Stations |

Why do I use magnetic couplings in these settings?

I need equipment that operates without leaks or contamination. Magnetic couplings provide a sealed barrier, which is essential for handling abrasive materials, hazardous chemicals, and high-pressure systems. I see improved safety and reduced downtime in these facilities.

- I use magnetic couplings in agitators and conveyors for cement plants.

- I rely on them for pumps and compressors in oil and gas facilities.

- I install them in coal plants to prevent dust and gas leaks.

- I trust them in generating stations for maintenance-free operation.

⚙️ Note: Osenc’s engineering team helps me design custom assemblies for unique industrial challenges. Their expertise ensures that every solution meets strict safety and performance standards.

In summary, magnetic couplings deliver leak-free, wear-resistant, and maintenance-friendly solutions for pumps, mixers, and many other industrial applications. I always choose Osenc for reliable neodymium magnets and custom assemblies that keep my operations running smoothly.

Advantages Over Mechanical Couplings

Safety

Magnetic couplings deliver superior operational safety compared to mechanical couplings. I see this advantage every time I work with sealed systems or hazardous materials. The absence of physical contact means I avoid friction, wear, and the risk of mechanical failure. Magnetic couplings create an effective hermetic seal, which prevents leaks and protects both equipment and personnel.

Here’s a comparison that highlights the safety benefits:

| Feature | Magnetic Couplings | Mechanical Couplings |

|---|---|---|

| Physical Contact | No | Yes |

| Wear and Tear | Minimal | Significant |

| Leak Prevention | Effective hermetic seal | Prone to leaks due to seals |

| Maintenance Requirements | Lower (no lubrication needed) | Higher (requires lubrication) |

| Vibration Tolerance | High (compensates for misalignment) | Low (sensitive to misalignment) |

| Safety | Reduced risk of mechanical failure | Higher risk of failure |

🛡️ I trust magnetic couplings to reduce risk and enhance safety in every project. Osenc’s neodymium magnets help me achieve reliable sealing and long-lasting protection, especially in critical environments.

Efficiency

Magnetic couplings improve efficiency across multiple industries. I notice smoother operation, fewer breakdowns, and higher productivity after switching from mechanical couplings. The elimination of friction and wear means my equipment runs longer and requires less downtime. I see these improvements in water treatment, food processing, energy generation, and automation.

| Industry | Efficiency Improvements |

|---|---|

| Water Treatment Facilities | Elimination of leaks and contamination, longer service life, lower operational costs. |

| Food and Beverage Industry | Improved sanitation, reduced cleaning cycles, higher productivity, compliance with safety standards. |

| Energy Generation | Reduced vibration and wear, extended equipment lifespan, reliable low-maintenance operation. |

| Industrial Automation | Smoother operation, fewer breakdowns, improved efficiency in high-speed or high-precision applications. |

- I see up to 80% fewer maintenance hours in water treatment plants.

- Food processors report higher productivity and better compliance with safety standards.

- Energy facilities experience extended equipment lifespan and reduced vibration.

⚡ Magnetic couplings help me achieve consistent, high-efficiency performance. Osenc’s custom magnet assemblies support my drive for productivity and reliability.

Cost

Magnetic couplings offer significant long-term cost savings. I pay more upfront for high-quality materials and precision manufacturing, but I save money over time due to minimal maintenance and reduced friction losses. Mechanical couplings may cost less initially, but frequent repairs and downtime increase expenses.

| Coupling Type | Initial Costs | Long-term Costs |

|---|---|---|

| Magnetic Couplings | Higher due to materials and manufacturing processes | Lower due to minimal friction losses and maintenance-free operation |

| Mechanical Couplings | Lower initial costs | Potentially higher due to maintenance needs and friction losses |

- I spend less on spare parts and labor.

- My equipment runs longer between service intervals.

- I avoid costly shutdowns caused by leaks or mechanical failures.

💰 I always recommend magnetic couplings for projects focused on total cost of ownership. Osenc’s expertise in neodymium magnets ensures I get the best value and performance for my investment.

In summary, magnetic couplings deliver unmatched safety, efficiency, and cost advantages over mechanical alternatives. I rely on these solutions to keep my operations running smoothly and profitably.

Selecting Magnetic Couplings

Factors to Consider

When I select a magnetic coupling for an industrial application, I always start by evaluating the most critical factors. The right choice ensures reliable performance and long service life. Here are the main points I consider:

- Torque Requirements: I determine the power, speed, and torque needed. I always match the coupling’s nominal torque rating to my application.

- Operating Environment: I check for chemical compatibility, temperature extremes, and how often the equipment will run.

- Physical Size Constraints: I measure the available space and make sure the coupling fits within those limits.

- Coupling Design: I look for designs that handle misalignments or support vertical loads if my setup requires it.

- Maintenance Needs: I decide if I want a maintenance-free design or if periodic checks are acceptable.

💡 Tip: I always consult Osenc for custom neodymium magnet solutions when my project has unique torque or space requirements.

Matching Type to Application

I match the type of magnetic coupling to the specific needs of my process. Each industrial environment presents its own challenges, so I tailor my selection accordingly:

- I request custom designs for unique industrial requirements.

- I choose magnetic couplings for aggressive environments, such as those with corrosive liquids or gases.

- I select the design based on torque needs, ensuring the coupling can handle the load.

- I use magnetic simulation (FEA) to optimize custom couplings for my application.

| Application Scenario | Recommended Coupling Type | Key Benefit |

|---|---|---|

| Corrosive Chemicals | Sealed Magnetic Coupling | Leak prevention |

| High Torque Machinery | Radial or Coaxial Coupling | Stable torque transfer |

| Confined Spaces | Disc or Axial Coupling | Compact installation |

🛠️ I rely on Osenc’s engineering team to help me design and simulate custom assemblies for demanding environments.

Installation Tips

Proper installation is essential for optimal performance and longevity. I follow these best practices to ensure success:

- I make sure all machines are securely installed and fixed in place.

- I clean every component thoroughly to remove dirt or damage.

- I gather the right tools, such as straightedges, feeler gauges, or laser alignment systems.

| Criteria | Description |

|---|---|

| Torque requirements | I specify coaxial or disc coupling based on load. |

| Operating conditions | I consider temperature, corrosion, and pressure. |

| Installation space | I use disc couplings for tight spaces and coaxial for high torque. |

| Quality standards | I check for ISO or industry certifications. |

⚙️ Note: I always prepare carefully for clutch alignment. Precise alignment directly impacts the performance and service life of my machines.

I trust Osenc for magnetic couplings that meet strict quality standards and simplify installation. Their support helps me achieve reliable, long-lasting results in every project.

I define magnetic coupling as a contactless method for transferring torque using magnetic fields. I rely on this technology for its wear-free operation and hermetic sealing.

Key industrial benefits include:

- Extensive use in pumps, compressors, and mixers for leak prevention and reliability

- Hermetic sealing reduces maintenance costs and contamination risks

- Contactless design boosts efficiency and safety

I trust Osenc for custom neodymium magnet solutions. I recommend exploring magnetic coupling options for specialized project needs. 🚀

FAQ

What is the main advantage of magnetic coupling?

The main advantage is contactless torque transfer. I eliminate wear, reduce maintenance by up to 80%, and prevent leaks. This makes my equipment safer and more reliable. 🛡️

Can magnetic couplings handle high temperatures?

Yes, magnetic couplings can operate from -40°C to 150°C. I select Osenc’s neodymium magnets for their stability and performance in extreme environments. 🌡️

How do I choose the right magnetic coupling for my application?

I consider torque, speed, environment, and space. I consult Osenc’s engineering team for custom solutions. They help me match the coupling to my exact needs. 🧑🔧

Are magnetic couplings maintenance-free?

Magnetic couplings require minimal maintenance. I do not need to lubricate or replace seals. I only perform routine checks, which saves me time and money. ⏱️

What industries benefit most from magnetic couplings?

Industries like chemical, pharmaceutical, and food processing benefit most. I use magnetic couplings in pumps, mixers, and conveyors to prevent leaks and contamination. 🏭

Can magnetic couplings protect my equipment from overload?

Yes, magnetic couplings provide built-in overload protection. If the load exceeds the limit, the coupling slips. This feature prevents damage and extends equipment life. ⚡

Does Osenc offer custom magnetic coupling solutions?

Yes, Osenc specializes in custom neodymium magnet assemblies. I rely on their expertise for unique shapes, sizes, and performance requirements. They support my projects with tailored solutions. 🧲

How long do magnetic couplings last?

Magnetic couplings can last over 10 years with proper use. I see extended service life because there is no physical contact or wear. This durability lowers my total cost of ownership. 📈

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.