- Material goes into the drum.

- The magnetic field pulls iron or steel bits to the drum.

- The drum turns and moves the magnetic stuff away.

- Clean stuff falls out, and the drum drops the magnetic bits in a new spot.

I know how does a magnetic drum separator works helps me pick the right machine for my job. I use magnetic drum separator machines in mining, recycling, and food factories to keep things clean and safe.

I think learning about the magnetic parts and steps makes my work faster and better. 🧲🚀

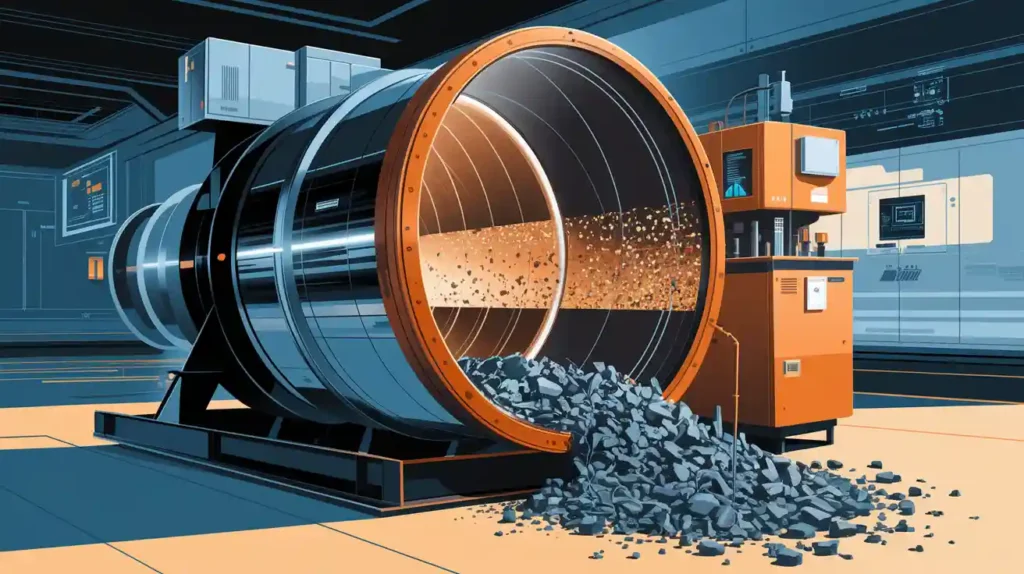

How Does The Magnetic Drum Separator Work

A magnetic drum separator works by using a spinning drum and a strong magnet to pull out metal bits from other stuff.

I see this every day in my job. When I ask myself, “how does a magnetic drum separator work,” I remember these steps:

- I put the mixed material onto the drum.

- The stationary magnet inside the drum makes a magnetic field.

- The magnetic field grabs ferrous tramp metal and other magnetic pieces.

- The drum spins and moves the magnetic stuff away from the clean material.

- The clean, non-magnetic stuff falls out in one place. The magnetic drum separator drops the metal bits in another spot.

I think the working principle is simple but very smart. The separator does not stop. It keeps pulling out metal bits all the time. This helps me work faster and safer.

Separation Process

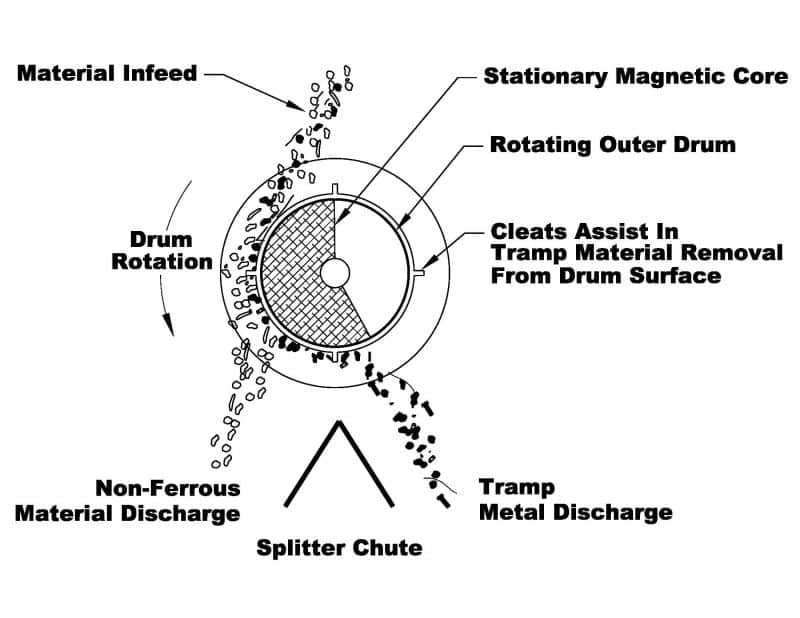

Material Entry

By feeding the raw material onto the drum surface. Sometimes the vibrating feeder to spread the material evenly. This makes sure every bit touches the magnetic field. The magnetic drum separator works best when the material is not too wet or too dry.

Magnetic Attraction

When the material touches the drum, the stationary magnet inside creates a strong magnetic field. This field pulls in all the magnetic particles. I see the contaminant attraction happen right away. Ferrous tramp metal and other magnetic bits stick to the drum. Non-magnetic stuff keeps moving forward.

Drum Rotation

The drum keeps spinning. As it turns, the magnetic particles stay stuck to the drum because of the magnetic field. The non-magnetic materials slide off and fall into a different spot. I watch the separator do this over and over. The working principle makes sure the magnetic drum separator never misses a piece.

Discharge

When the drum turns to a spot where there is no magnet, the magnetic field stops. The magnetic particles drop off the drum into a separate bin. The clean material goes out another way. I like how the separator keeps the process going without stopping. This makes magnetic separation fast and easy.

| Component | Function |

|---|---|

| Magnetic Drum | Spins fast to grab and hold magnetic particles from the mix. |

| Stationary Magnet System | Makes a strong magnetic field inside the drum to attract metal bits. |

| Splitter | Separates magnetic stuff from non-magnetic stuff at the end of the drum. |

| Vibrating Feeder | Spreads material evenly on the drum for better magnetic separation. |

The working principle of magnetic drum separators depends on many things. The size and shape of the particles, how wet they are, and how strong the magnet is all matter. I always check my separator and clean it so the magnetic field stays strong.

Types of Magnetic Drum Separators

When I choose magnetic drum separators, I see three main types. Each type works best for different jobs and materials. I want to share what I learned about them.

Dry Magnetic Drum Separator

A dry magnetic drum separator works with dry, coarse materials and does not need water.

I use dry magnetic drum separators when I have big, dry pieces. I put the material on the drum. The magnetic field pulls the metal bits to the drum. The clean stuff falls away. I like dry magnetic drum separators because they do not need water. This saves money and makes my work easy in dry places.

Here are some things I see with dry magnetic drum separators:

- I use them in mining, recycling, and food factories.

- They work fast with lots of material.

- They do not work well with very small or weak magnetic pieces.

- Sometimes, I see dust or static. I clean the machine to stop this.

😊 Tip: I use dry magnetic drum separators when I do not have water or when I want to save water.

Wet Drum Magnetic Separators

Wet drum magnetic separators work with wet or slurry materials and catch fine or weak magnetic particles.

I use wet drum magnetic separators when my material is wet or very small. I mix the material with water. The drum spins in the water. The magnetic field pulls the tiny metal bits to the drum. The clean, non-magnetic stuff goes away with the water.

I see wet drum magnetic separators in these jobs:

- I use them in mining, ceramics, and chemical factories.

- They work best with fine, wet materials.

- They need water, so I use them where water is easy to get.

- They give me very clean products.

Here is a table I made to help me remember the difference:

| Type | Best For | Needs Water | Works With Fine Material | Where I Use It |

|---|---|---|---|---|

| Dry magnetic drum separator | Dry, big pieces | No | No | Mining, recycling |

| Wet drum magnetic separators | Wet, small particles | Yes | Yes | Mining, ceramics, chemicals |

💧 Note: I use wet drum magnetic separators when I want to catch very small or weak magnetic bits.

Rare Earth Magnetic Separator

A rare earth magnetic separator uses very strong magnets to catch even the smallest and weakest magnetic particles.

I use rare earth magnetic drum separators when I need to get the cleanest product. The rare earth magnets are much stronger than normal magnets. They help me catch fine and weak magnetic pieces that other magnetic drum separators miss.

I use rare earth magnetic drum separators for:

- Mineral sands and glass making

- Cleaning ceramics and fillers

- Iron ore and gold mining

- Making very pure products

Here is what I like about rare earth magnetic drum separators:

- They work all the time and do not need much fixing.

- They save money because they do not need extra machines.

- They help me make better products faster.

🧲 Pro Tip: I use rare earth magnetic drum separators when I want the best and cleanest results.

Compare the Types

I made a list to help me choose the right magnetic drum separators:

- Dry magnetic drum separator: Best for dry, big pieces. No water needed.

- Wet drum magnetic separators: Best for wet, small pieces. Needs water.

- Rare earth magnetic separator: Best for very fine or weak magnetic bits. Makes the cleanest product.

I always look at my material and my job before I pick which magnetic drum separators to use. This helps me work faster and get better results. 😃

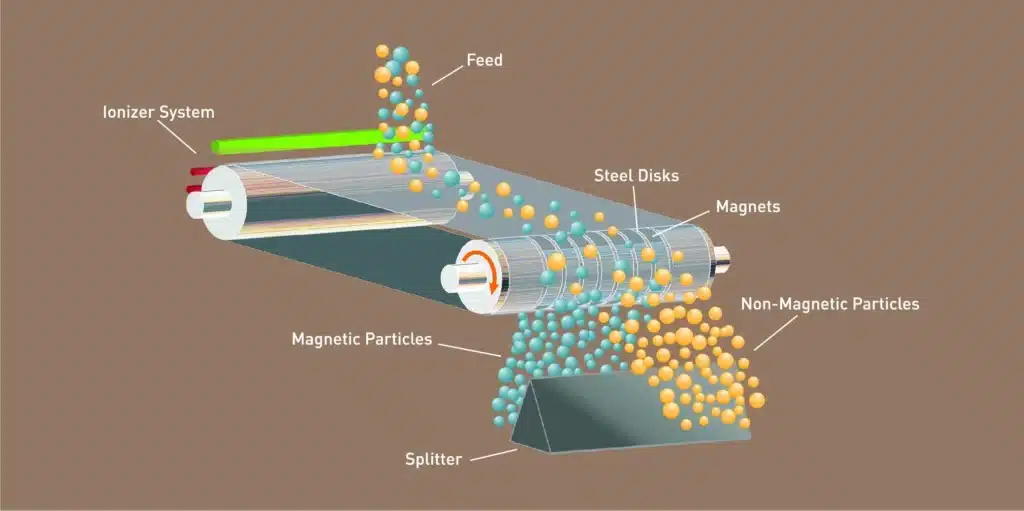

Feed and Discharge

How do the feed and discharge parts work in a magnetic drum separator?

The feed puts material into the drum, and the discharge takes out the clean and metal parts.

I see these two parts every day when I use my magnetic drum separator. They help me do my job fast and easy. Let me tell you how they work.

Feed System

The feed system is where I put the mixed material. I use a hopper or a chute. Sometimes, I use a vibrating feeder. The feeder shakes and spreads the material. This makes sure the material goes onto the drum in a thin, even layer. If the layer is too thick, the magnet cannot catch all the metal bits. If the layer is too thin, I waste time.

Here is what I do with the feed:

- I pour the material into the hopper.

- The feeder moves the material to the drum.

- The material spreads out on the drum shell.

- Every piece gets a chance to touch the magnetic field.

🧑🔧 Tip: I always check the feeder. If it gets stuck, I clean it right away. A clean feeder helps the separator work better.

Discharge System

The discharge system takes out the separated materials. I see two main discharge points:

- One for the clean, non-magnetic stuff.

- One for the magnetic metal bits.

When the drum turns, the non-magnetic material falls off first. It drops into a bin or onto a conveyor belt. The magnetic bits stay on the drum until they reach the end. When the drum moves past the magnet, the metal bits fall off into a different bin.

Applications

Mining

I use magnetic drum separators in mining to keep my minerals clean and safe.

When I work in mining, I see a lot of rocks and dirt mixed with metal bits. I want to get the good minerals out and leave the bad stuff behind. Magnetic drum separators help me do this job fast and easy.

Here is how I use them in mining:

- I put the mined material into the separator.

- The drum pulls out iron, steel, and other magnetic pieces.

- The clean minerals go to the next step in mineral processing.

- The metal bits drop into a bin for recycling or safe removal.

I like that I can change the magnetic strength. Sometimes I need to catch big metal pieces. Sometimes I want to catch tiny bits. I use high-intensity drums for fine minerals like mica or iron-coated sand. I use low-intensity drums for bigger, stronger metals.

Recycling

I use magnetic drum separators in recycling to make my work faster and cleaner.

When I work in recycling, I see a lot of mixed trash. Some things are metal, some are not. I want to get the metal out so I can recycle it and make money.

Here is how I use magnetic drum separators in recycling:

- I put the mixed recycling on a conveyor belt.

- The drum separator pulls out all the iron and steel.

- The clean plastic, glass, and paper go to other machines.

- The metal goes to the recycling industry for new products.

I like that the separator works by itself. I do not need to pick out the metal by hand. This saves me time and keeps my hands safe. The separator also helps me get more pure recycling materials. This means I can sell them for more money.

Food Industry

I use magnetic drum separators in the food industry to keep food safe and clean.

When I work with food, I want to make sure there are no metal bits in what people eat. Sometimes, machines break and drop small metal pieces into the food. I use the separator to catch these before they go into the next step.

Here is how I use them in food:

- I put the raw food on a conveyor belt.

- The drum separator pulls out any iron or steel pieces.

- The clean food goes to packing or cooking.

- The metal bits go into a bin for safe removal.

I see that using magnetic drum separators helps me follow food safety rules. I do not want to have recalls or make people sick. The separator also keeps my machines from breaking. If there is no metal in the food, my machines last longer.

Chemical Processing

I use magnetic drum separators in chemical processing to keep my powders and products clean and safe. 🧪✨

When I work in a chemical factory, I see many powders and small grains. Sometimes, these materials have tiny metal pieces inside. I do not want metal in my chemicals. It can make my products bad. It can also break my machines. I use a magnetic drum separator to fix this problem.

FAQ

What materials can a magnetic drum separator remove?

I can remove iron, steel, and other magnetic metals.

I use it for rocks, powders, food, and trash. It works best with things that have metal bits inside. 🧲

How do I clean a magnetic drum separator?

I let the drum clean itself.

The drum spins and drops metal bits into a bin. I empty the bin when it gets full. Sometimes, I wipe the drum with a cloth. 🧹

Can I use a magnetic drum separator for wet materials?

Yes, I can use it for wet stuff.

I use a wet drum separator for slurries or fine powders mixed with water. It works better for small or weak magnetic bits. 💧

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.