Neodymium Magnet Chamfered

You may have seen many neodymium magnets with chamfers. None of them have sharp edges and corners. Have you ever wondered why neodymium manufacturers do this?

As a custom neodymium magnet supplier, Osenc will explain how chamfers are important for neodymium magnets, and how we can make them.

1. Why neodymium magnets need chamfers?

Neodymium magnets are widely used in various fields, thanks to their high magnetic energy, remanent magnetism, and cost-effectiveness.

However, they are fragile and easy to break, so it is easy for them to be bumped during the production or application processes, which leads to broken edges and corners, etc. Especially in the process of producing large magnets. For this reason, neodymium magnets are usually chamfered.

*In the magnetic simulation, chamfering is also a factor that must be considered.

2. Benefits of chamfering neodymium magnets

1). Chamfering can avoid broken edges and corners on neodymium magnets.

Quality assurance for magnets includes various aspects. One of them is to inspect the magnets’ appearance. For Osenc, a magnet with scratches, broken edges and corners will be put aside as a defective product.

Making chamfers on the edges and corners of neodymium magnets won’t bring unacceptable negative effects on their magnetic performance. On the contrary, this design is very helpful for avoiding necessary visual quality problems.

2). Chamfers help neodymium magnets obtain better surface coating quality.

It is a process before coating applications. And chamfers can increase the surface area on the magnets’ edges and corners by eliminating sharp angles, therefore, enhancing the adhesion of the coating layer.

If the edges and corners have sharp angles – like 90 degrees – the coating will have less adhesion on those spots, which are weak spots and more likely to have issues, and then bring bigger quality issues to the whole piece of magnet.

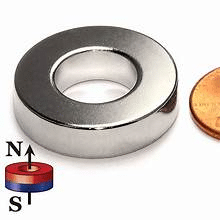

3. How neodymium magnets look like after chamfering

From the picture above, we can see that a square neodymium magnet has its right-angle edge chamfered. After chamfering, each right angle of the magnet has a certain magnitude, which will reduce the possibility of broken edges and corners during assemblies and applications.

4. How chamfers are made on neodymium magnets

There are different ways to chamfer neodymium magnets. It will depend on what the magnets actually are to choose the best fit chamfering method.

Common chamfering methods include:

Use chamfering machine

Use vibration machines for chamfering before plating

In a nutshell, chamfering can help neodymium magnet suppliers prevent unnecessary broken edges and corners. It is a fundamental step for assuring the quality of custom neodymium magnets.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.