Demagnetizing a magnet refers to decreasing or eliminating the magnetic strength of the magnet, such that it does not attract metal or disrupt other objects or devices around it. This is necessary in keeping the accuracy of the tools, electronics, and industrial equipment. Magnets can also become ineffective over time; however, controlled demagnetization keeps them safe and accurate when necessary. The most common ones are handheld demagnetizers, alternating current, and heat, all of which are effective and safe in de-magnetizing magnetic fields without harming the material.

How to demagnetize correctly?

To demagnetize correctly, you need to understand how magnetic domains work. These tiny regions create a magnetic force, and demagnetization means disrupting their alignment. The best method depends on the magnet’s type and use, whether using heat, alternating current, or handheld demagnetizers. Always proceed carefully to avoid damage. These are some common and effective methods used to demagnetize a magnet.

1. Handheld demagnetizers

The handheld demagnetizer is a convenient and effective item to small magnets or metal tools such as screwdrivers, tweezers, and bits. It operates through the creation of an alternating magnetic field, interfering with the internal alignment of the magnet. To apply, slowly pass the magnet through the device multiple times, gradually pulling it off to create a uniform distribution of residual magnetism safely.

2. Alternating Current

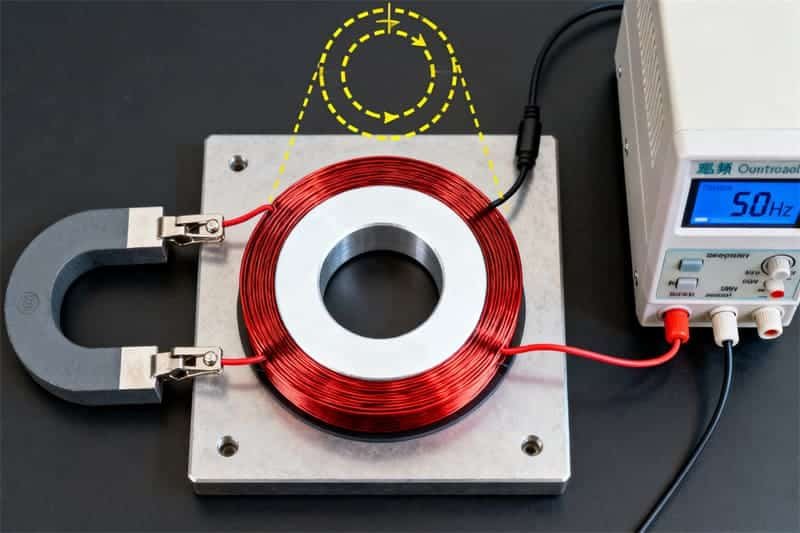

Demagnetization with alternating current (AC) is an ancient but effective technique. When a magnet is exposed to an AC field, the alternating polarity causes a repetitive rearrangement of its magnetic domains, cancelling magnetism over time. When gradually withdrawing the magnet from the field, the oscillating effect is neutralized. The technique is applied in industries and electrical applications.

3. Heating the Magnet

When a magnet is heated beyond its Curie temperature, it completely loses its magnetic properties. At this temperature, thermal energy breaks the orderly arrangement of magnetic domains, destroying magnetism. Nevertheless, this approach is non-reversible to most materials as cooling might not revert the initial structure. It is not an ordinary tool as it is designed to be used in scientific or controlled labs. For NdFeB magnets, heating can also compromise protective coatings—see common options like Nickel or Epoxy.

4. Striking the Magnet

When a hammer is used to strike a magnet or any other hard material, the internal vibrations that occur in such a strike affect the alignment of the magnetic domains. Mechanical shocks may weaken or destroy magnetism, particularly when the shocks are repeated, and when the magnets are heated at the time of the shock. It works, but is not accurate and may cause physical damage to fragile or brittle magnets—if impact risk exists, consider protected cup-style magnets instead.

5. Reverse the Magnetic Field

Applying a reverse magnetic field counteracts the magnet’s existing polarity, gradually neutralizing it. In this method, the magnet is put into an oppositely oriented controlled magnetic field, and the intensity is varied with time. It is an accurate, non-destructive technique of recalibration of sensitive instruments or reconditioning permanent magnets. Careful monitoring ensures complete demagnetization without inducing residual reverse magnetism.

6. Electromagnets

Demagnetism can be done with electromagnets and regulating the current flow. When current runs in the opposite direction or fluctuates in polarity, it disrupts domain alignment in nearby ferromagnetic materials. Reducing the current strength slowly assists the magnet in losing its charge slowly. This is particularly useful with workshop equipment and industrial machinery parts.

7. Use a Commercial Demagnetizer

Commercial demagnetizers are designed for convenience and precision. They use alternating fields or pulsed magnetic energy to remove residual magnetism from parts, tools, or assemblies, especially screw-mounted components. Most feature adjustable intensity levels and automated cycles, making them ideal for repetitive industrial applications. Simply insert or pass the object through the demagnetizer as per the manufacturer’s instructions for best results.

9. Mechanical Demagnetization

In mechanical demagnetization, the magnetic domains are randomized by some physical motion or vibration. It can be done by shaking, bending, or vibrating the material that is magnetized. This disturbance of the inner structures by the energy of these motions leads to the disappearance of magnetism. Although not as efficient as electrical techniques, it is a fast and easy way of performing light demagnetization.

10. Self Demagnetization

There are some kinds of magnets that gradually lose their magnetism over time, either as a result of temperature, magnetic fields, or age. This is a process that occurs naturally, and the domain alignment decays gradually and sporadically. Self-demagnetization, though not a process, is one of the reasons why old magnets are likely to grow weak without any treatment.

Demagnetizing Procedure

The method of demagnetizing depends on the nature, strength, and size of a magnet. The initial one is to select the right method- alternating current, heating, or a handheld demagnetizer. Introduce the magnet to the demagnetizing source gradually and press it out; this is to ensure the scan is a uniform magnetic loss. Never make abrupt turns, or ever place the magnet in your bare hands. The industrial applications often force the magnets through the coils with decreasing magnitudes. This ought to be conducted under regulated circumstances so that no residual magnetism or overheating occurs. After demagnetizing the magnet or tool the magnetic field detector should be used in order to verify full neutralization.

How the Demagnetizer Works?

The principle of a demagnetizer is that it creates a growing and contracting magnetic field, and this field destroys the magnetic field alignment between magnetic domains of a magnetized material. As a magnet is drawn across this field, the alternating, quickly changing polarity causes the domains to slide by each other until the domains become disoriented and equalize themselves. The field strength is gradually reduced in such a manner that the magnet neither acquires another polarity, but rather the field brings the magnet to a neutral condition. Most demagnetizers use coils of alternating currents to form such vibrating forces of magnetism. It relies on the principle of magnetic hysteresis, in which the regulated exposure to weakening fields leaves the object with no magnetic field and zero residual magnetism.

Why should you use a Magnetizer/Demagnetizer tool?

Demagnetizer/ magnetizer is easy and safe as it is accurate. It allows the rapid magnetization or demagnetization of metal tools without the complex arrangements and heating. Such tools may help technicians, electricians, and engineers in taking care of efficiency when working with the screws, motors, or sensors. The undesired magnetism, which may cause incorrect measurements or electronic interference, is removed by a demagnetizer. Conversely, they use magnetic tools such as screwdrivers to find it easier to hold metallic objects. When a tool can perform two functions simultaneously, it is considered to be versatile and less susceptible to equipment wear and tear. It is compact in size and easy to operate, and can also be used in industrial factories and at home.

How Does Pulse Demagnetization Work for Large Magnets?

The technique of pulse demagnetization is a highly technical procedure given to large or powerful magnets that require the regulation of extremely high accuracy. It is the flow of powerful and short electrical pulses in coils used to surround the magnet. The polarities of every pulse vary and go weaker and weaker, forcing the magnetic domains to get unorganized. This pulsed current system removes overheating and provides uniform demagnetization to the total body of material. In industrial systems, programmable controllers are common to enlarge or decrease the pulse duration and amplitude. The result is a totally demagnetized magnet with no mechanical or heat damage, which can be used in heavy equipment, motors, and sensitive measuring instruments.

Demagnetisation technology (alternating magnetic field fundamentals)

The principle of the demagnetisation technology is that of an alternating magnetic field that needs a changing current to create a magnetic flux that changes direction every time. This back-and-forth motion causes the magnetic domains in the substance to reorient themselves in non-uniform orientations, canceling the overall magnetism. Its operability is pre-determined by a set of parameters including the strength of the field, rate of current, shape of coils, and length of exposure. This is done by reducing the field step-by-step to zero in the demagnetizers used in industry to prevent left polarities. This simplistic process enables simple and consistent demagnetization of refined, non-mechanical components of gears, shafts, and fine instruments with accuracy, without creating unnecessary turbulence to magnetic sensors and electronic infrastructure.

Field strength, coil opening/length, current, number of turns

The performance of a demagnetizer depends heavily on design factors such as field strength, coil size, and number of turns. A stronger field removes magnetism more effectively, while larger coil openings accommodate bigger parts. The coil’s length and current determine how deep the demagnetizing effect penetrates. More turns increase magnetic flux but may also raise heat levels. Balancing these parameters ensures an optimal and safe demagnetization process, allowing consistent results across different materials and magnet sizes in both industrial and laboratory environments.

Conclusion

Demagnetization is essential for precision, safety, and performance in various applications. Knowing the various approaches can help you adopt the appropriate approach to suit your needs. The objective is the same, no matter what technology is applied, heat, current, or pulsed, that is neutralizing magnetic influence efficiently and safely.

FAQs

Why You Would Want to Demagnetize a Magnet?

You might need to demagnetize a magnet to avoid interference with the electronic equipment, sensors, or other equipment to allow proper and safe working.

How do I temporarily deactivate a magnet?

To temporarily inactivate a magnet, place it into an alternating magnetic field or temporarily place it in an area of a demagnetizer. The magnetic domains lose their alignment but can easily be remagnetized when they are required.

How to remagnetize a magnet at home?

It is possible to remagnetize a magnet at home, rubbing it with a strong permanent magnet or by means of a DC-powered coil. Make sure that the poles are oriented correctly to achieve maximum reactivation strength

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.