You demagnetize a permanent magnet by messing up the alignment of its magnetic domains. If you ask, “how do you demagnetize a permanent magnet,” you can heat it, hit it, or use an alternating current. Each way changes how the magnet acts. When you ask, “how do you demagnetize a permanent magnet,” always look at what kind of permanent magnet you have. Neodymium magnets need special care. If you ask, “how do you demagnetize a permanent magnet,” remember that it can be forever or just for a short time. “How do you demagnetize a permanent magnet” safely? Always follow the steps, especially if the magnet has a special cover or a special job. 🧲

Demagnetization Methods for Permanent Magnets

Using Alternating Current

You can demagnetize a permanent magnet by exposing it to an alternating magnetic field generated by a coil that is specifically sized for the magnet’s shape and material.

This method works for many materials, including neodymium magnets, using a coil and a power source that provides a strong alternating current. As a general guideline, the field can be set between 50 and 100 kA/m with a low frequency of about 1 to 8 Hz, and each demagnetization cycle typically lasts 6 to 20 seconds depending on the magnet size and grade.

⚡ Tip: Always wear safety goggles and gloves when using electrical tools, and make sure the demagnetizer or coil is properly grounded and rated for the current you plan to use.

Step-by-step instructions:

- Put the magnet fully inside the center of the coil so that the entire magnet is inside the strongest part of the field.

- Turn on the alternating current and confirm that the current, frequency, and temperature stay within the recommended limits for your magnet type.

- Slowly reduce the current to zero in small steps, because a gradual decrease helps randomize the domains more evenly than a sudden shutoff.

- Take the magnet out of the coil and measure its strength with a gauss meter or a simple pull-force test to confirm that the demagnetization level meets your needs.

This process gradually randomizes the magnetic domains, causing the magnet to lose most or all of its magnetism. According to Osenc, this method is suitable for magnets with special coatings such as PTFE or Parylene, which help protect the magnet surface during demagnetization.

In workshop tests and small production lines, this AC method is often used to demagnetize tools, jigs, and neodymium components before assembly so that they do not attract metal dust or interfere with nearby sensors.

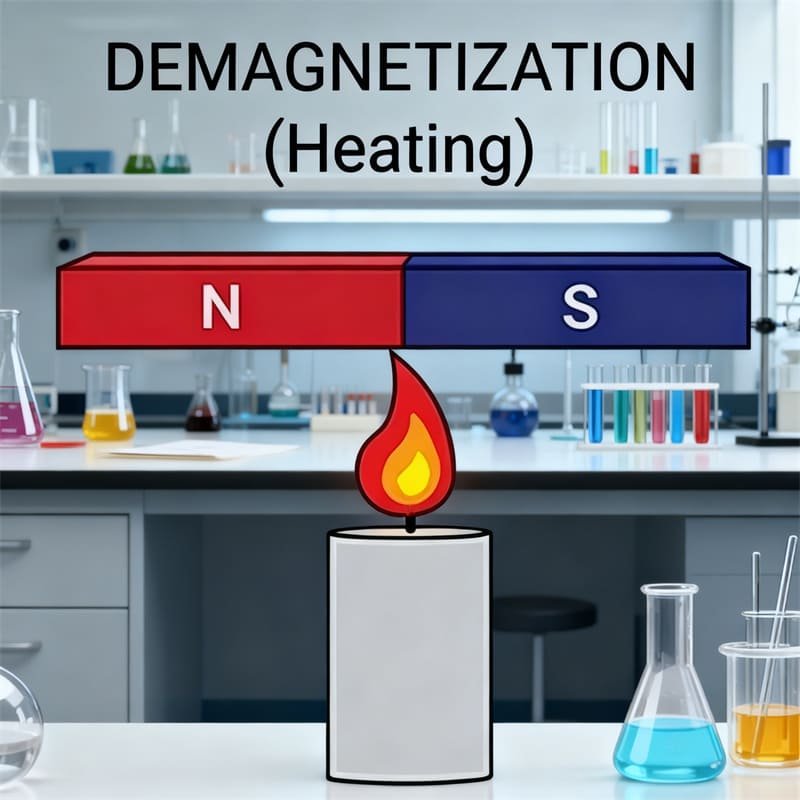

Heating Above Curie Temperature

Heating a magnet above its Curie temperature will completely remove its magnetism, but this is usually only used in controlled industrial or recycling processes because the magnet cannot be restored afterward.

The Curie temperature is when the magnet stops being magnetic. For neodymium magnets, it is between 310°C and 370°C. For samarium cobalt, it is 700°C to 800°C. Ferrite magnets lose magnetism at 450°C.

| Material | Curie Temperature (°C) |

|---|---|

| Neodymium (NdFeB) | 310-370 |

| Samarium Cobalt | 700-800 |

| Ferrite | 450 |

Step-by-step instructions:

- Put the magnet in an oven that controls temperature.

- Heat the magnet above its Curie temperature.

- Let the magnet cool down slowly.

🔥 Note: Wear heat-resistant gloves and keep a fire extinguisher close. Do not heat magnets with flammable coatings.

Osenc’s neodymium magnets with PTFE or Parylene coatings are designed for demanding conditions, but you should always confirm the coating’s maximum temperature and chemical stability before using heat as a demagnetization method.

Physical Impact

Striking or dropping a magnet can cause partial demagnetization by disturbing the alignment of its domains, but the effect is hard to control and is mostly used as a rough method for older AlNiCo magnets rather than for modern neodymium parts.

Hitting or dropping messes up the magnetic domains. This works best for AlNiCo magnets. It can lower magnetism by up to 30%.

Step-by-step instructions:

- Put the magnet on a strong surface.

- Hit the magnet gently with a tool that is not metal.

- Check the magnet’s strength after each hit.

🛡️ Tip: Always wear safety goggles and gloves. Use plastic wedges for big magnets.

Osenc’s coatings like nickel and epoxy help stop magnets from chipping when hit.

Striking The Magnet

You can reduce a magnet’s strength by striking it with a hammer or dropping it from a height, especially if it has robust coatings like nickel or epoxy to prevent chipping.

Safety precautions:

- Wear safety goggles and gloves.

- Slide magnets apart, do not pull.

- Use plastic wedges to separate.

- Keep magnets far apart.

- Store in a dry, cool place.

- Never drill or cut magnets.

- Keep away from heat.

- Store away from children.

Step-by-step instructions:

- Hold the magnet on a flat surface.

- Hit the magnet with a hammer.

- Look for cracks or chips.

🧤 Alert: Neodymium magnets break easily. Osenc’s coatings help stop breaking, but always be careful.

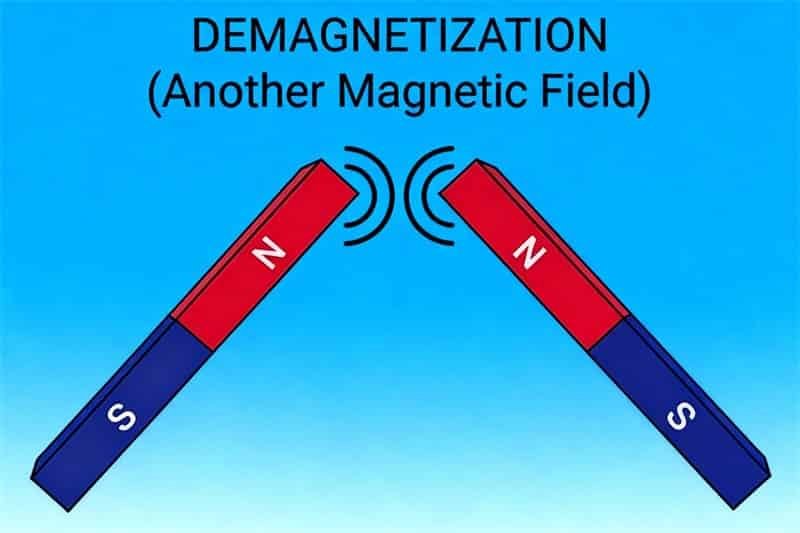

Reverse The Magnetic Field

Applying a reverse magnetic field can demagnetize a permanent magnet by using a strong field in the opposite direction, which drives the domains into a less ordered state. A uniform coating helps this method work more effectively. Osenc’s treatments, such as PTFE and gold, provide smooth, corrosion-resistant surfaces that support stable demagnetization.

Step-by-step instructions:

- Put the magnet in a demagnetizer or coil.

- Use a strong reverse magnetic field.

- Slowly lower the field strength.

🧲 Note: Smooth coatings and fewer flaws make demagnetization easier and better.

How coatings affect demagnetization:

- Coatings make surfaces smooth and stop chipping.

- Nickel plating makes magnets stronger.

- Coatings that stop rust keep magnets safe.

- Good coatings help magnets demagnetize evenly.

Summary Table: Effectiveness of Demagnetization Methods

| Method | Effectiveness | Suitable for Neodymium | Notes |

|---|---|---|---|

| Heating above Curie temperature | High | Yes | Magnetism lost forever |

| Alternating current | High | Yes | Needs exact field settings |

| Physical impact | Moderate | Yes | Only some demagnetization |

| Striking | High | Yes | Be careful; coatings help protect |

| Reverse field | High | Yes | Even coating is important |

😊 Tip: Osenc designs and tests neodymium magnets with different coatings in real industrial projects, so their engineering experience can help you choose a demagnetization method that is both safe and effective for your specific application.

Magnetising and demagnetising magnetic materials

You change the magnetic properties of materials by magnetising or demagnetising them. Magnetising makes a material act like a magnet. Demagnetising takes away or lowers its magnetic power. You can use heat, hitting, or magnetic fields for both.

When you magnetise something, you line up its magnetic domains. You do this by putting the material in a strong magnetic field. You can use an electromagnet or a permanent magnet for this. The domains inside the material move and point the same way. This gives the material strong magnetism.

Demagnetizing does the opposite by disrupting the alignment of the domains so they no longer point in the same direction. You can use heat, hit the material, or use an alternating magnetic field. The demagnetization curve shows how much magnetism is left after these steps. This curve shows how magnetic strength drops when you change things.

Many industries need to magnetise and demagnetise materials repeatedly, so engineers rely on tested procedures, measured performance data, and safety standards to choose the right method. You see this in:

- Electric motors

- Medical devices

- Data storage technologies

Electric motors need magnets that are strong and work well. Medical devices need magnets that can be cleaned and used again safely. Data storage needs magnets that can save and erase information exactly.

The demagnetization curve helps engineers predict how a magnet behaves after repeated use or heating, and real test data based on this curve is often used to set process limits in motors, sensors, and medical devices. For example, some neodymium magnets can lose around 20–30% of their strength after repeated demagnetization cycles, so engineers usually track flux density or pull force before and after each process.

You can use tables to see how different materials react:

| Material | Magnetising Ease | Demagnetising Ease | Typical Strength Loss (%) |

|---|---|---|---|

| Neodymium | High | Moderate | 30 |

| Ferrite | Moderate | High | 20 |

| AlNiCo | High | Low | 10 |

🧲 Tip: Always check what kind of magnet and coating you have before you start. This helps you pick the best way and keeps your magnet safe.

How Do You Demagnetize a Magnet Safely?

You can safely demagnetize a magnet if you follow safety rules and pick the right way for your permanent magnet.

Safety Precautions

When you work with permanent magnets, especially strong neodymium magnets, you need to protect both yourself and your equipment from injury and damage. Here are some important safety tips:

- 🧤 Wear safety glasses and gloves to keep your eyes and hands safe.

- 🚫 Do not let kids or pets near magnets. They could swallow them.

- 🩺 Stay at least 20 cm away from pacemakers and other medical devices.

- 📱 Keep magnets away from phones and computers so they do not get ruined.

- ⚠️ Be careful not to pinch your skin. Magnets can snap together fast and trap your fingers.

- 🧭 Store magnets far from compasses and navigation tools.

- 🧑🔬 If you are allergic to nickel, do not touch nickel-coated magnets for a long time.

| Injury Type | Description |

|---|---|

| Pinching Hazards | Magnets can catch your fingers or skin and hurt you. |

| Equipment Damage | Magnets can break or damage machines if they snap together. |

| Medical Device Interference | Strong magnets can mess up pacemakers and other medical electronics. |

Choosing the Right Method

You need to pick the best way to demagnetize a magnet by looking at its size, coating, and what you use it for. Small neodymium magnets work well with alternating current. Big magnets might need to be heated above their Curie temperature. If your permanent magnet has a special coating like PTFE or Parylene, check if it can handle heat and chemicals before you start.

What your magnet is made of and its grade change how it acts. For example, neodymium magnets with dysprosium can take more heat. This makes them good for cars or planes. If you use magnets in medical tools, pick ways that keep coatings safe and let you use the magnet again.

💡 Osenc helps with custom magnet projects and gives advice. You can ask for help to pick the right way to demagnetize your permanent magnet, especially if you need a special solution.

Is Demagnetization Permanent?

Demagnetization can be permanent or reversible, depending on how the magnet is treated, the magnet material (such as neodymium, ferrite, or AlNiCo), and the operating environment. If you heat a magnet above its Curie temperature, it loses magnetism for good. Strong impacts can also make it lose magnetism forever. If you use a weaker method, you can often get the magnet’s strength back.

Factors Affecting Permanence

Many things decide if demagnetization stays:

- Heat: Heating a magnet above its Curie temperature for a long time causes permanent loss. If you heat it for a short time and let it cool, some magnetism may come back.

- Physical Shock: Dropping or hitting a magnet can mess up its domains. Sometimes you can fix this, but strong hits often cause damage that stays.

- Opposing Magnetic Fields: Strong outside fields can mess up domain alignment. You might fix this if you use the right method.

- Time and Corrosion: Over time, magnets get weaker as domains move. Uncoated neodymium magnets lose magnetism faster because of rust.

- Magnetic Aging: New magnets may lose about 1% of their flux over 100 years, and rare-earth magnets such as neodymium lose even less because of their high coercivity.

- Energy required: The energy needed to demagnetize a magnet depends on its size, material, and temperature.

🧲 Tip: High heat can cause losses that you can or cannot fix. Always check your magnet’s material and coating before you try to demagnetize it.

| Factor | Reversible Loss | Permanent Loss | Notes |

|---|---|---|---|

| Heat (below Curie) | Yes | No | Magnet gets better when cooled |

| Heat (above Curie) | No | Yes | Magnetism gone forever |

| Physical Shock | Sometimes | Sometimes | Depends on how hard the hit is |

| Opposing Field | Sometimes | Sometimes | Strong fields do more damage |

| Corrosion/Aging | No | Yes | Slow loss that stays |

Remagnetizing a Permanent Magnet

You can often make a magnet strong again with easy steps:

- You can often restore a weak magnet’s strength with simple steps, such as rubbing a strong magnet along its surface to realign the domains.

- You can also wrap copper wire around the magnet and connect the wire to a battery, creating an electromagnet that helps restore the magnet’s field.

- Use a magnetic energizer tool. These tools send pulses to restore magnetism.

⚡ Note: If you work with big magnets, Osenc uses special tools to model and improve remagnetization. These tools show how magnets react to currents and fields. They help you get magnetism back in the way you want.

| Remagnetization Method | Effectiveness | Best Use Case |

|---|---|---|

| Strong Magnet Rubbing | Moderate | Small magnets at home |

| Electromagnet (Wire + Battery) | High | Medium or large magnets |

| Magnetic Energizer Tool | High | Magnets used in factories |

| Circuit Design & Simulation | Very High | Custom magnet assemblies |

😊 Tip: If you need help with remagnetizing magnets for motors, sensors, or medical devices, Osenc’s team can help you from start to finish.

The safest and most effective ways to demagnetize permanent magnets are alternating-current fields and heating above the Curie point. 🧲 Always consider the magnet’s type, coating, and application before choosing a method.

In engineering projects, teams usually start with AC or reverse-field demagnetization tests on sample magnets, record the before-and-after flux or pull force, and then define standard settings for the production line. This kind of testing-based approach reduces risk and makes sure the chosen method really fits the magnet and the application.

Here is a quick guide:

| Method | Effectiveness | Safety Risk | Best For |

|---|---|---|---|

| AC Field (Degausser) | Very High | Low | Sensitive applications |

| Heat (Curie Point) | Very High | High | Lab, bulk processing |

| Impact/Vibration | Low | Medium | Old, weak magnets |

- Put on gloves and goggles.

- Pick the right tools for the job.

- Mark parts that are demagnetized.

Osenc helps you with custom magnets and gives expert advice for any project.

FAQ

How can you tell if a magnet is demagnetized?

You can check with a paperclip or compass.

If the magnet cannot pick up a paperclip or move a compass needle, it lost most of its strength. You may see up to 90% less pull force.

Can you remagnetize a demagnetized magnet?

Yes, you can remagnetize most magnets.

Use a strong magnet or an electromagnet. Rub the weak magnet with a strong one. For best results, use a magnetic energizer tool.

Does dropping a magnet always demagnetize it?

No, dropping only reduces strength by about 10–30%.

You may see a small loss in power. Strong coatings help protect the magnet from damage.

Is it safe to heat a magnet to demagnetize it?

Heating works but can be risky.

High heat above the Curie temperature (e.g., 310°C for neodymium) removes magnetism forever. Always wear gloves and goggles. Never heat magnets with flammable coatings.

Which method is best for neodymium magnets?

Alternating current works best for neodymium magnets.

This method gives you control and protects coatings. Osenc recommends this for magnets with PTFE, Parylene, or gold coatings.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.