Many buyers are currently asking one key question before placing orders:

“Do you have an export license?”

We understand why. Export controls and compliance requirements do exist in the rare-earth supply chain, and some products may trigger additional licensing or documentation.

However, an important point is often missed:

Not all magnet materials involve controlled rare-earth elements.

Export controls exist — but we can supply non-controlled formulations

In NdFeB magnet production, certain heavy rare earth elements such as Dysprosium (Dy) and Terbium (Tb) (and in some contexts Samarium (Sm)) may be used to improve high-temperature demagnetization resistance.

For many standard applications, these additives are not required.

We work with qualified manufacturing partners who can produce and supply:

✅ Dy-free / Tb-free / Sm-free magnet material options (Dy/Tb/Sm Free)

Because these formulations do not contain those controlled additives, shipments of these products typically do not require an export license, which can simplify procurement and reduce uncertainty for overseas buyers.

Note: Compliance requirements can vary by destination, HS code/classification, end use, and customs declaration details. We can provide supporting documentation and help you confirm with your broker/import team.

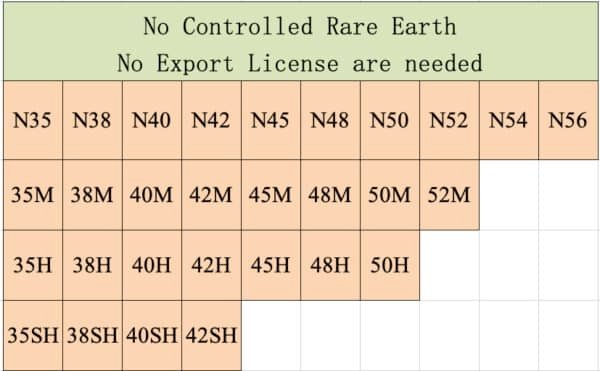

The Grades We Can Support (Example Range)

Depending on your size, temperature, coating, and application requirements, we can offer common grades such as:

-

- N35 / N38 / N40 / N42 / N45 / N48 / N50 / N52 / N54 / N56

-

- Temperature classes (subject to evaluation): M / H / SH

If your project is delayed due to export license concerns, send us your requirements and we’ll prioritize a Dy/Tb/Sm-Free solution first.

What This Means for Buyers

Choosing Dy/Tb/Sm-Free options can often deliver practical benefits:

-

- Simpler export process (no license concerns)

-

- More stable lead times (less approval uncertainty)

-

- Lower compliance friction for procurement teams

-

- More flexible sourcing for standard temperature applications

FAQ (What Buyers Usually Ask)

Q1: Are you saying export controls don’t exist?

No. Controls still exist. What we offer is an alternative supply option: magnet materials without Dy/Tb/Sm additives, which typically avoids export-license requirements related to those elements (final compliance depends on classification and regulations).

Q2: Will Dy/Tb/Sm-Free magnets be strong enough?

In many standard applications, yes. For higher-temperature use, we can review your operating conditions and recommend the best grade/structure/coating, or propose an engineering alternative. It simply makes mechanical processing more difficult.

Q3: Do the magnets can be ship by epxress or air cargo?

Yes. Neodymium magnets can be ship by both way. However, there is still a small chance that the shipment will be inspected by China customs. Such inspections can take 20-35 days. We recommend that customers adjust their procurement plans to ensure smooth production.

Send These 5 Details for a Fast Match

- Magnet size/drawing

- Target grade (or performance requirement)

- Operating temperature range

- Coating & corrosion requirements

- Quantity + delivery location/timeframe

We’ll reply with a recommended Dy/Tb/Sm-Free option and a quote range.

I’m Ben, with over 10 years in the permanent magnet industry. Since 2019, I’ve been with Osenc, specializing in custom NdFeB magnet shapes, magnetic accessories, and assemblies. Leveraging deep magnetic expertise and trusted factory resources, we offer one-stop solutions—from material selection and design to testing and production—streamlining communication, accelerating development, and ensuring quality while reducing costs through flexible resource integration.