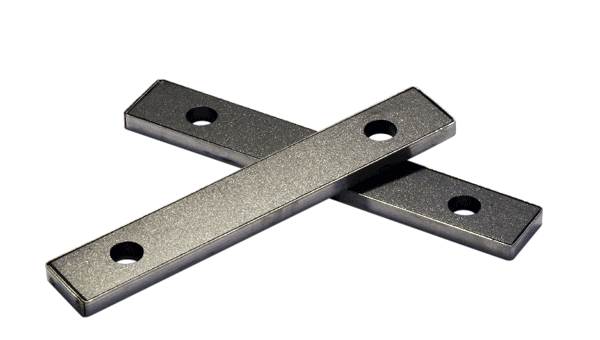

Teflon coated magnets

Two PTFE types: black (PTFE coating) and white (PTFE plastic)

Coefficient of friction < 0.1, second only to diamond

Temperature resistance: works up to 240–260 °C

PTFE coating has no pinholes, ensuring excellent chemical resistance

Teflon coated magnets

Teflon coated magnets are powerful magnets that have been coated with a layer of Teflon, a synthetic polymer known for its non-stick and high-temperature resistant properties. This coating provides excellent resistance to corrosion and chemicals, making these magnets suitable for use in harsh environments such as automotive, medical, and electronics industries. Teflon coated magnets are also highly durable and have good impact resistance, making them ideal for a wide range of applications, including medical equipment, sensors, motors, and magnetic separators.

2 types of Teflon

PTFE coating + Magnet (In regular that is black)

PTFE plastic + Magnet (In regular that is white)

We call it black PTFE magnet and white PTFE magnet

What is PTFE?

Teflon coating, also known as PTFE , or Polytetrafluoroethylene (commonly known as “the King of Plastic”). It is a synthetic fluoropolymer discovered by Roy Plunkett.

Teflon is a fluorocarbon-based polymer with multiple strong carbon-fluorine bonds. This feature makes it highly resistant to a variety of substances. For most regular consumers, Teflon is famous for its most common application on non-stick pans and other cookware.

Actually, thanks to the strength of the carbon-fluorine bonds, Teflon coatings are also widely used in containers,fluid agitation testing, and piping systems for reactive or corrosive chemicals

Advantages Of Teflon Coated Neodymium Magnets

PTFE is non-stick

Therefore, it can make PTFE-coated magnets easy to clean, and less likely for pollutants to accumulate on their surfaces. This coating is a good choice if keeping the magnets clean is an important consideration for you.

Low coefficient of friction

The coefficient of friction of PTFE coating is less than 0.1, which is only behind the diamond. This is an important feature to consider if your application will require the magnets to have smoothness to a certain extent.

Water resistance

The surfaces of neodymium magnets with PTFE coating will be shielded from water and many other liquids. Even during production, it is also difficult for them to be contaminated by various solutions, even the lubricants for machines. If there is dirt on their surface, you can clean them by gentle swiping.

Temperature resistance

PTFE coating can work properly within a wide range of temperatures, usually up to 240 °C – 260 °C without any problem. This is much higher than the working temperatures of neodymium magnets themselves. It will be an ideal solution if your applications will be under high-temperature conditions.

Wear resistance

A surface coated with PTFE will have excellent resistance against tear and wear. Just imagine how many times you will use non-stick cookware to make food. The non-stick coating will still last for years. Consider this coating if the durability of the coating is important for your applications.

Shockproof

PTFE is a highly durable plastic material with exceptional shockproof performance. It is widely used in various industries, including electronics, automotive, and aerospace, due to its excellent thermal and chemical resistance, low friction, and long-term stability.

Chemical resistance

Some other types of coating seem to completely cover the neodymium magnets inside at the first glance. However, technically speaking, this is not true. For example, for the coating of natural rubber, there are very small pinholes, which are not visible to the naked eye. Therefore, the neodymium magnets will have a faster gradual degradation.

However, PTFE coating won’t have this issue. It doesn’t have pinholes, so it has much more excellent resistance to acid and alkaline pollutants. Therefore, it can assure a longer life span for the neodymium magnets inside.