Quality Management

Table of Contents

Osenc Magnet Co.,Ltd is a neodymium magnet supplier that prefers quality over cost-effectiveness since the day it was founded. And we have obtained the ISO 9001 certification in order to be better and better.

If quality management is one of your top priorities, you should definitely consider sending an email to Osenc. Especially, if the performance of the magnets has a significant impact on the results of your projects, then let Osenc make sure the magnets you receive will be up to par, rather than falling short of your standards, which brings unexpected issues to your entire schedule.

Certification

Needless to say, it is important to work with a certified supplier. However, it is equally important to understand the limits of certification. A supplier with ISO 9001 doesn’t guarantee you a product without quality issues.

For many suppliers, getting an ISO 9001 certification is like an exam. Although one of the targets for the ISO 9001 standard is the “continuous improvement” concept, there is no real quantification of this continuous improvement or simply of maintaining it after certification is acquired.

There is a common misunderstanding about ISO 9001 certification – believing that acquiring a standard certification by a company is the same as the product quality standard that a company delivers.

This is a mistake to think so because the standard doesn’t determine product quality itself, since certification only looks at the company’s internal behaviors, and processes, etc.

Quality management Needs Solid Foundation

Osenc people deeply understand quality is a systematic project, and ISO 9001 certification alone doesn’t guarantee product quality. Quality management begins with the top management of a company.

The competitive strategies that they choose determine the overall quality level of their products. If they decide to compete with a strategy that emphasizes quality, reliability, and long-term success, then they will lay a solid foundation for their product quality.

On the contrary, if they decide to compete with a strategy that focuses on cost-effectiveness, it will be very likely the first action will be to reduce the cost of materials, skip procedures, etc. And this direction will surely lead to a lower overall quality level.

Quality Originates from Optimum Materials

No matter what quality management method you apply to your products and production, one thing will remain unchanged. That is, good quality comes from optimum materials.

You can never achieve good quality by using cheaper but worse materials. This is the same as making a meal. If you use rotten apples, how can you make a cup of delicious apple juice?

As for Osenc as a magnet supplier, we prefer to focus on the best type of material – neodymium magnets for various types of production. From regular shapes to irregular shapes , from micro magnets to giant sizes magnets, all are made with this superior material, so that they have better performance for the users.

It is always our biggest honor to hear our customers are happy with what they buy from us!

Sub-Suppliers for Quality

It is rare for a supplier to do every procedure regarding manufacturing a product. Doing everything alone is technically and finally illogical. It is a common practice to work with material sub-suppliers and outsource procedures to technique providers.

The key point is what kind of partners you choose to work with. For Osenc, our principle is to work with those who focus on quality, reliability and efficiency. Therefore, one of the basic criteria is to pick those also with certificates of ISO 9001 and ISO16949.

In this way, we will be able to build a complete supply chain that opts for quality and performance. And it will minimize the risk of potential magnet defeats that are only noticeable in the long term.

Full-time quality inspectors

Many manufacturers do have a complete quality management system. Unfortunately, it is common for manufacturers to assign employees to take quality inspection as a part of their work, rather than function as full-time quality inspectors, which can lead to compromised quality.

Unquestionably, it is the people that get things done. As one of the fundamental management practices, it is necessary to assign the right people to do the right things in the right way.

At Osenc, we have people who function solely as quality engineers, and they only do things regarding quality inspections. Their tasks include inspections for incoming inspections, during production inspections, and pre-shipment inspections.

Measure to Evaluate Quality Properly

Magnets look simple. It is almost impossible to evaluate the quality of magnets properly with naked eyes and bare hands. You will need quite a few devices and instruments to obtain some data for technical analysis (That’s why we can see many magnet buyers complain what they receive from their suppliers fall short of standard).

Therefore, you should definitely consider working with a supplier who measures their magnets. Ask them to give you some numbers about the magnets, rather than only adjectives like good, strong, powerful, etc.

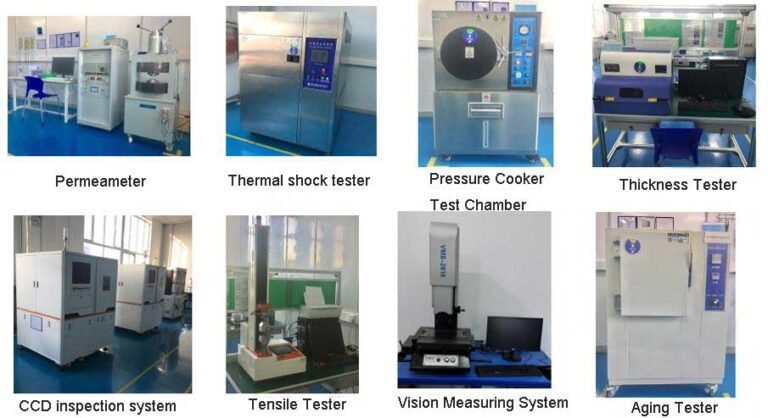

Osenc has invested in some of the most important testing facilities for evaluating magnets’ quality. With these facilities, we can reveal the real performance of magnets.

The inspection instruments include 3 types:

Magnetic performance: Permeameter, Helmholtz coil, Gauss meter, and magnetic declination tester

Appearance & dimension: Precise calibrator, micrometer, and dimension imager

Surface finishing: Salt spray chamber, coating thickness tester, and climate testing chamber.

Pre-shipment Inspection for Timely Deliveries

Besides producing good magnets, it’s equally important to deliver on time. And the last important thing before leaving our warehouse is to do pre-shipment inspections. Especially, make sure the packages comply with the requirements of IATA regulations.

Magnets are special goods for shipping since they have magnetism and will interfere with the proper functions of various meters on airplanes. Improper packing and failures on IATA tests can result in denials of shipping requests by the government and shipping companies.

Osenc always does pre-shipment inspections to make sure the packages are under the mandatory minimum value of magnetic impact. And we will also obtain the IATA reports for your magnets. They will assure smooth deliveries of magnets to you!

Inspection Tool